A Cylindrical Transverse Flux Switched Reluctance Linear Motor with Modular Stator

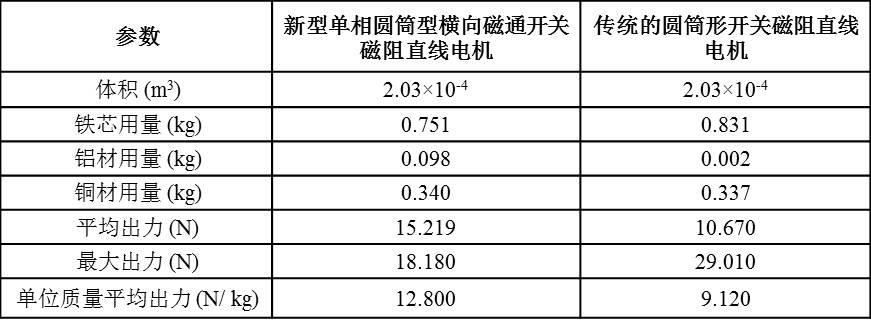

A technology of transverse magnetic flux and linear motors, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the eddy current loss of the motor, the average output of the motor is not high, and reducing the volume ratio of the motor output, so as to reduce the eddy current loss , Ease of production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

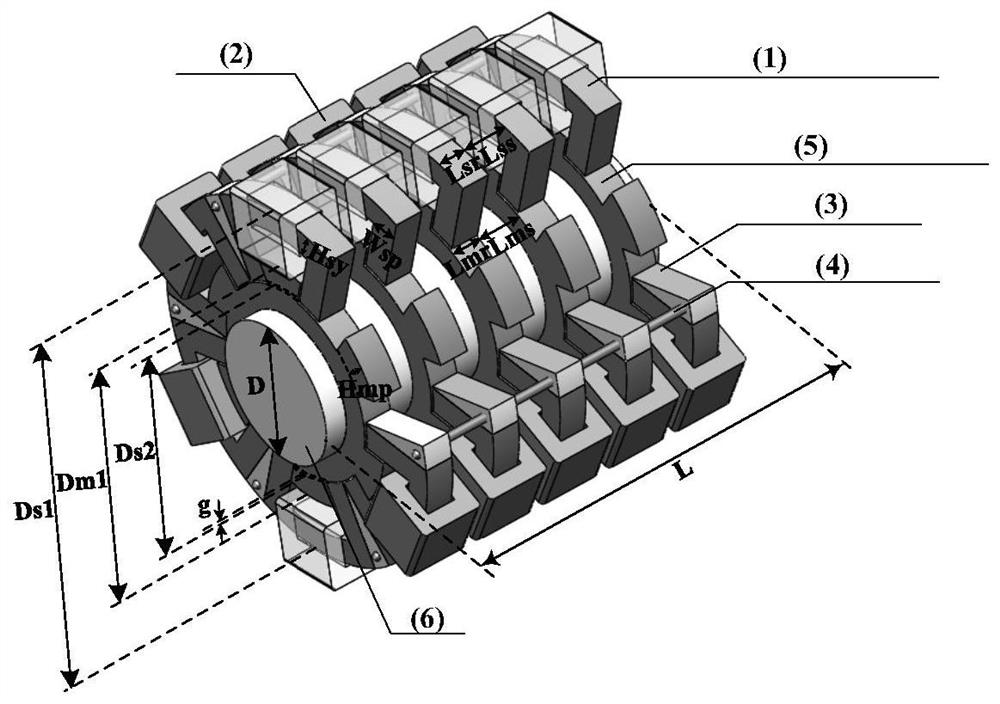

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

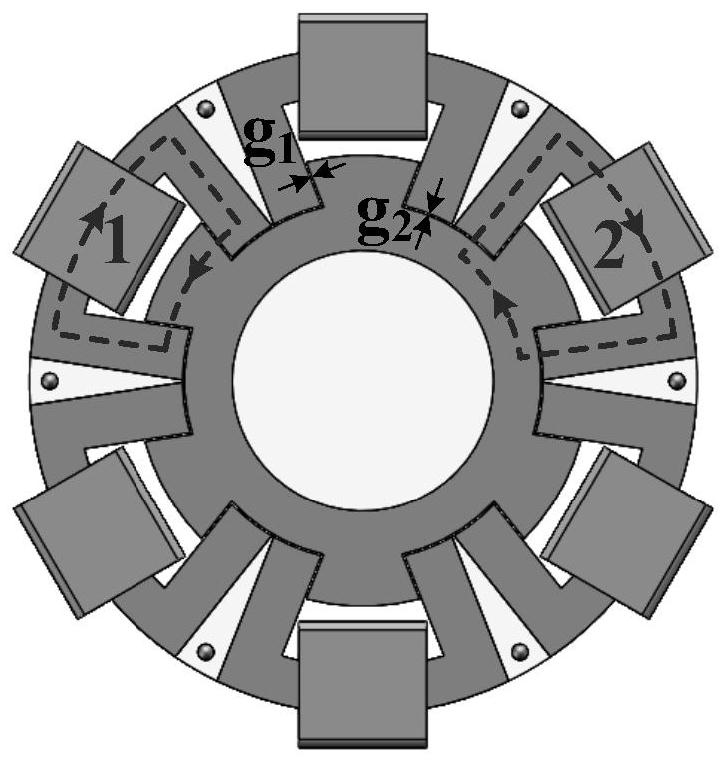

[0014] The single-phase cylindrical transverse flux switch reluctance linear motor of this embodiment consists of a U-shaped modular stator (1), a stator winding (2), a stator gasket (3), a gasket fixing screw (4), a mover Composed of a ferromagnetic ring (5) and a mover shaft (6). The modular stator and the stator gasket are placed alternately on the cross-section, the ferromagnetic ring of the mover is sleeved on the mover shaft, and the salient poles on the mover ring are buckled at the opening of the U-shaped modular stator (1); in the circumferential direction The winding direction of the two adjacent stator windings is opposite; all the windings in the longitudinal direction have the same winding direction; there are 6 windings in the circumferential direction; the angle between the two adjacent windings is staggered by 60°.

[0015] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com