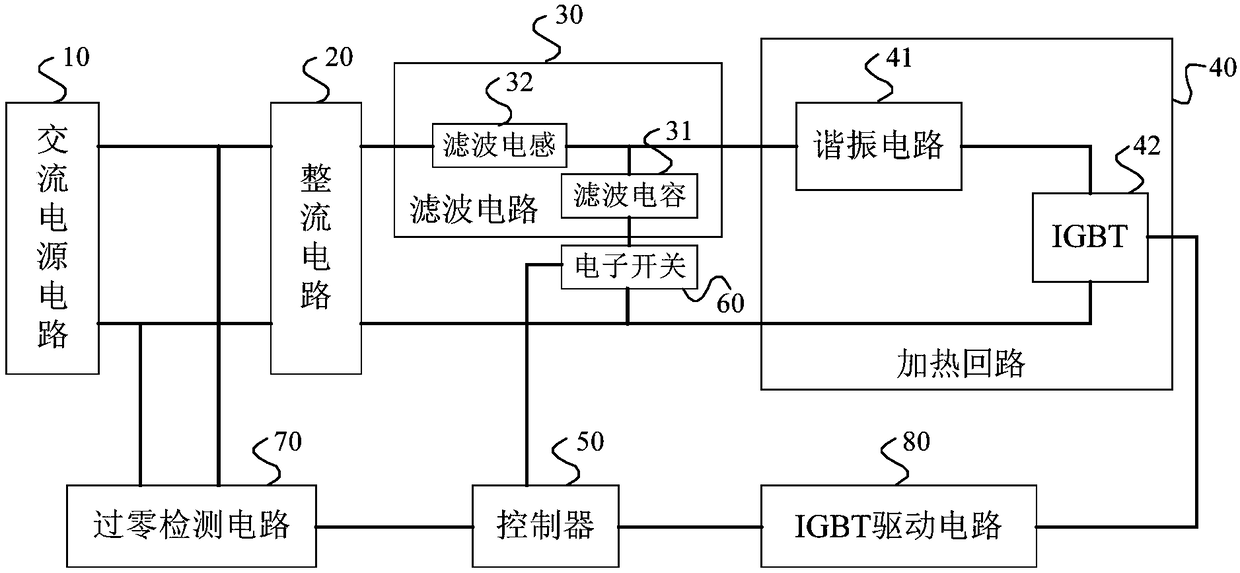

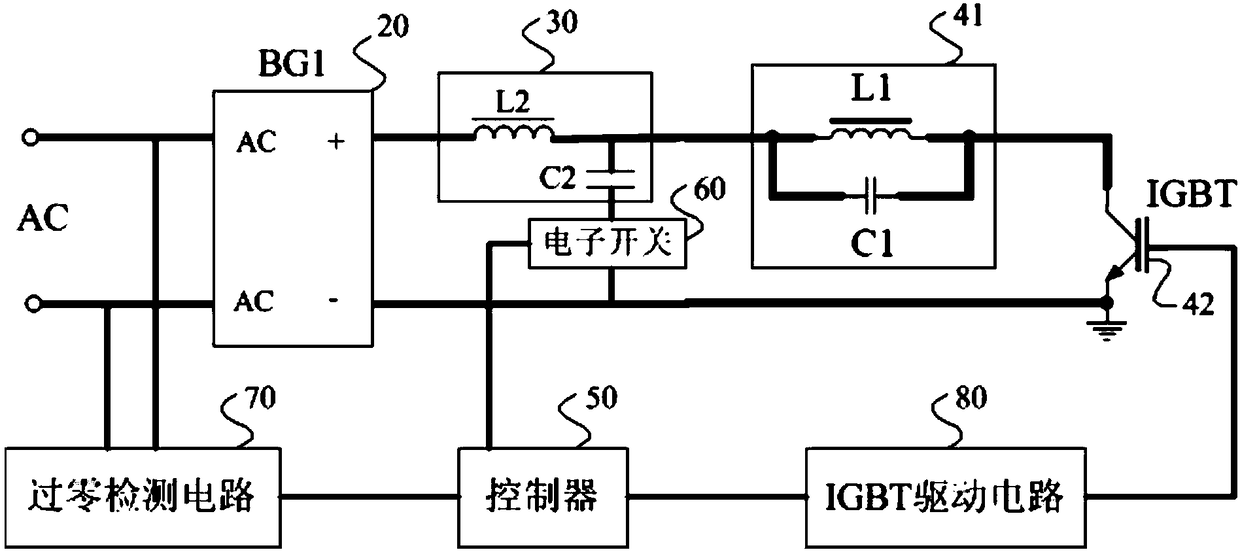

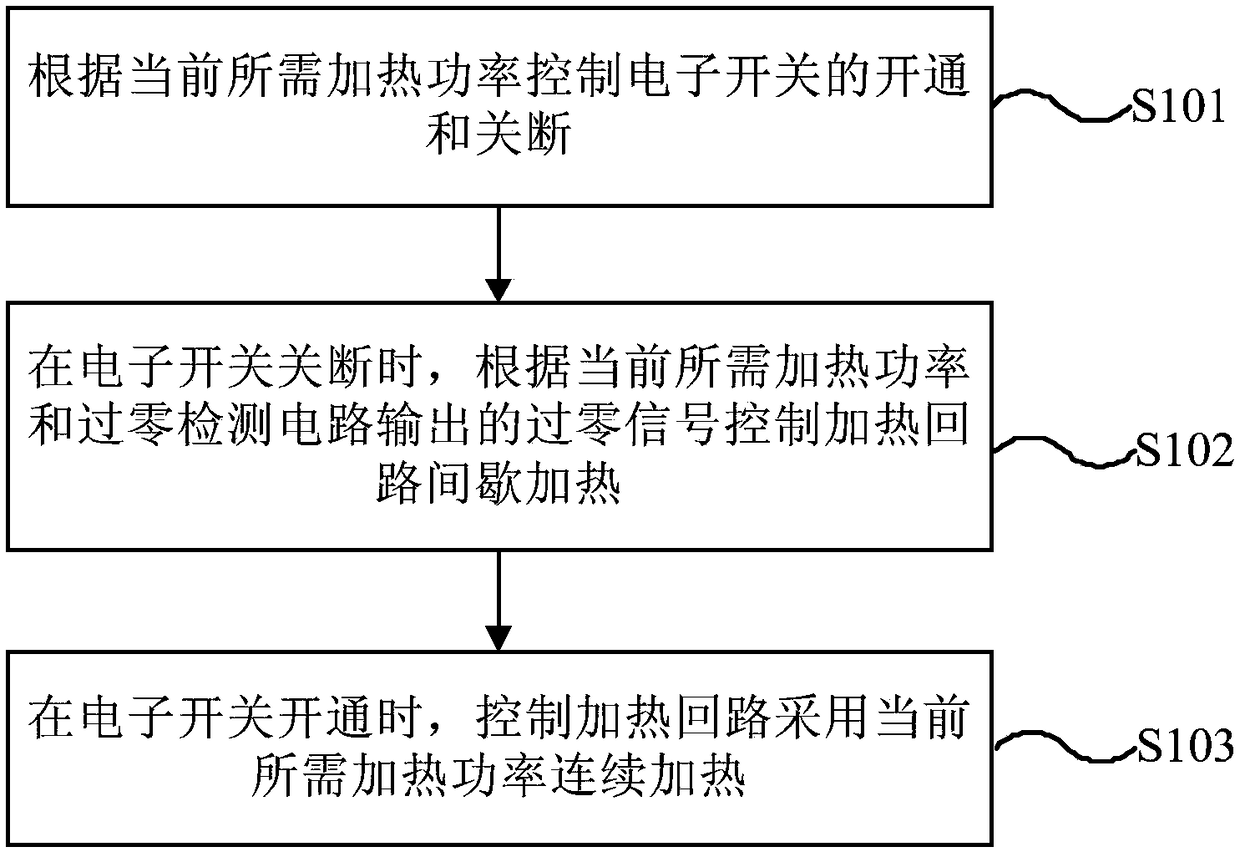

Electromagnetic heating device and power control method

An electromagnetic heating device and heating power technology, applied in the direction of electric heating device, induction heating control, electric/magnetic/electromagnetic heating, etc., can solve the problems of large loss, large IGBT heat generation, too small power, etc., to achieve extended service life, increased power range, avoiding the effects of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the current low-power heating method of the electromagnetic heating device, the resonant capacitor is switched. During low-power heating, the resonant frequency is very high, resulting in a large IGBT heating; the lower the power, the smaller the resonant capacitor, and the higher the resonant frequency. , the greater the heat generation of the IGBT, therefore, in the actual implementation, in order to ensure the safe operation of the circuit, the minimum power can only be 300W; and when the mains voltage is high, the IGBT overheating protection is easy to occur, the reliability is low, and the actual power is far away. Much higher than 300W. The way of relay + diode chopping, through the unidirectional conductivity of the diode, closes half a cycle, so that the electromagnetic heating device works for 10ms and stops for 10ms, and the power is halved; when realizing lower power heating, it is necessary to greatly reduce the electromagnetic For example, when the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com