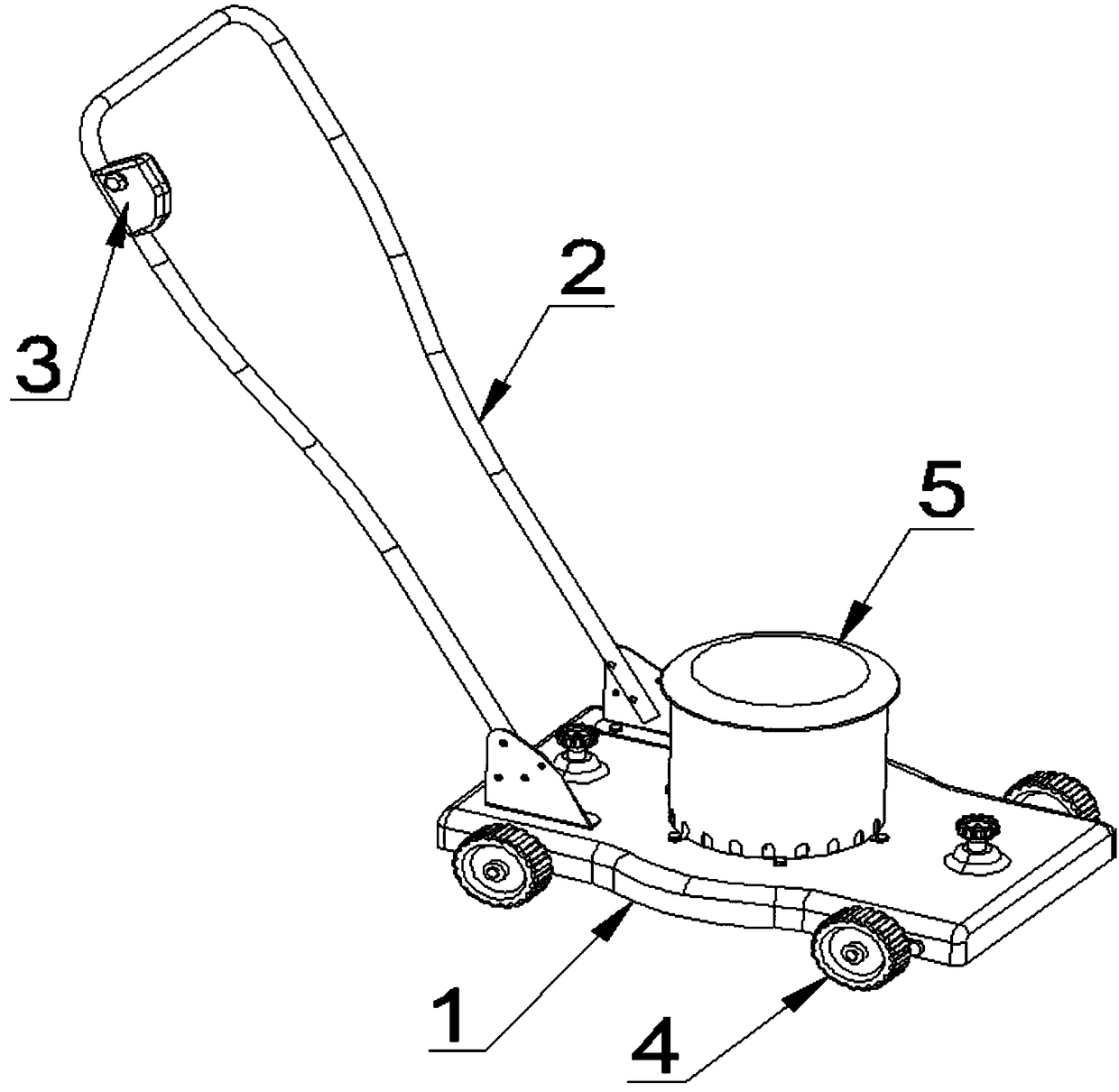

Soil heavy metal pollutant dispensing device

A technology for heavy metals and pollutants, applied in the restoration of polluted soil, etc., can solve the problems of low operating efficiency, high treatment cost, and high local accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

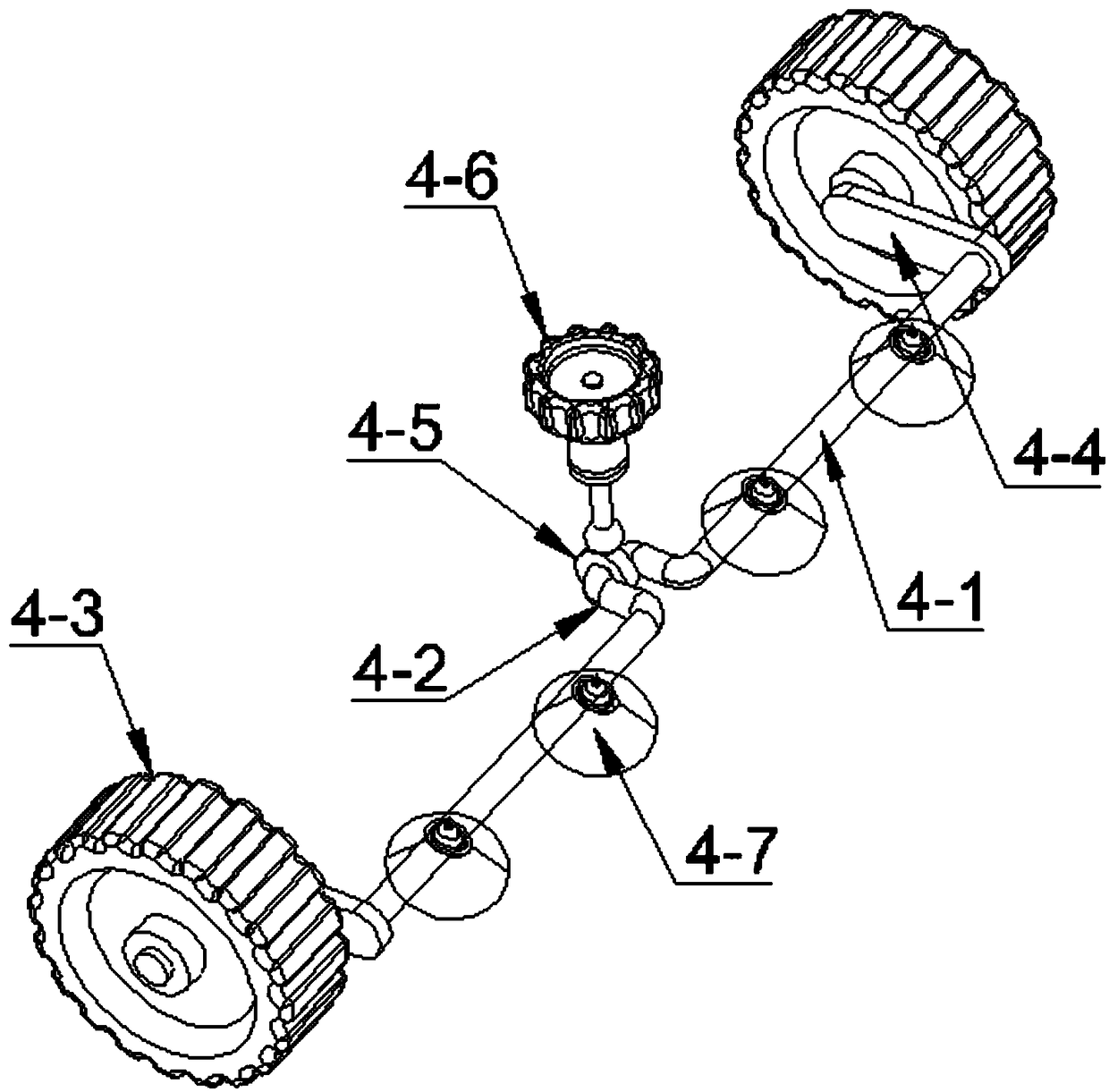

Method used

Image

Examples

Embodiment 1

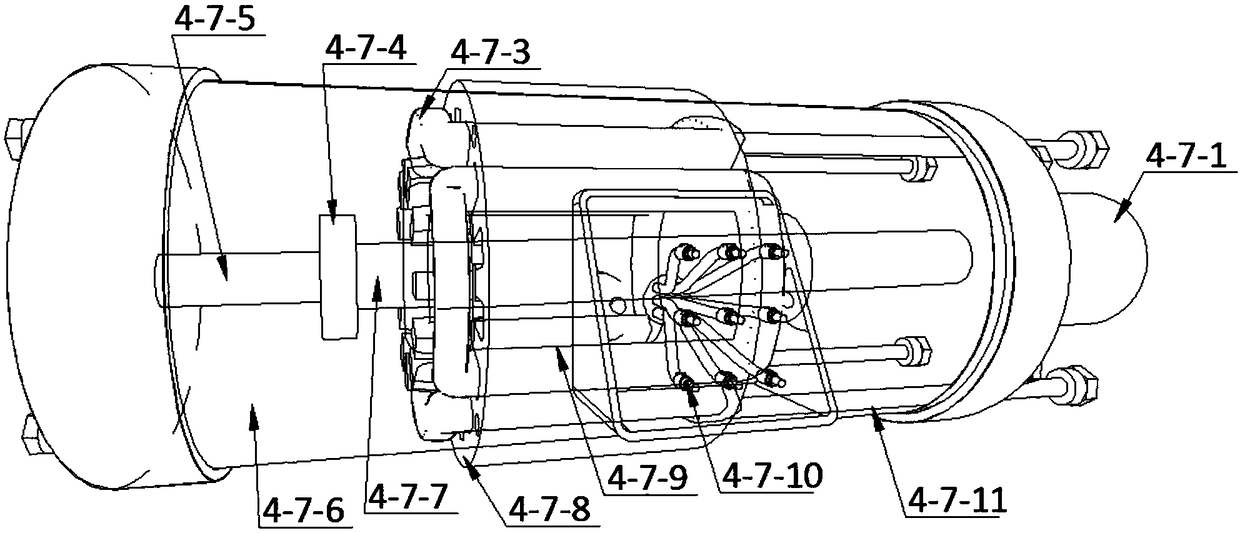

[0085] Prepare the primary impeller 4-7-1-4-5-5 of the present invention according to the following steps, and in parts by weight:

[0086] S1: In the stirred tank reactor, add 334.9 parts of pure oxygen steam vaporized water and 126.7 parts of N-methyl-N-(tetradecanoyl) glycine, start the stirrer in the stirred tank reactor, set The rotation speed is 127rpm, and the hot lubricating oil conduction heater in the stirred tank reactor is started to raise the temperature to 142.9°C;

[0087] S2: Take another 133.3 parts of berkelium nanoparticles, and add berkelium nanoparticles to 126.1 parts of polymerized naphtha with a mass concentration of 129ppm for dispersing berkelium nanoparticles;

[0088] S3: Add the dispersed berkelium nanoparticles into the stirred tank reactor, adjust the pH value at 4.7, keep warm and stir for 125 minutes; then stop the reaction and let stand for 6.59×10 minutes;

[0089] S4: Add 129.4 parts of (methoxymethyl)oxirane and stir evenly, carry out the ...

Embodiment 2

[0096] Prepare the primary impeller 4-7-1-4-5-5 of the present invention according to the following steps, and in parts by weight:

[0097] S1: In the stirred tank reactor, add 559.0 parts of pure oxygen steam vaporized water and 168.3 parts of N-methyl-N-(tetradecanoyl) glycine, start the stirrer in the stirred tank reactor, set The rotating speed is 173rpm, and the hot lubricating oil conduction heater in the stirred tank reactor is started to raise the temperature to 143.0°C;

[0098] S2: Take another 188.8 parts of berkelium nanoparticles, and add berkelium nanoparticles to 168.4 parts of polymerized naphtha with a mass concentration of 359 ppm for dispersing berkelium nanoparticles;

[0099] S3: Add the dispersed berkelium nanoparticles into the stirred tank reactor, adjust the pH value at 8.2, keep warm and stir for 192 minutes; then stop the reaction and let stand for 12.03×10 minutes;

[0100] S4: Add 238.6 parts of (methoxymethyl) oxirane and stir evenly, carry out t...

Embodiment 3

[0107] Prepare the primary impeller 4-7-1-4-5-5 of the present invention according to the following steps, and in parts by weight:

[0108] S1: In the stirred tank reactor, add 450.0 parts of pure oxygen steam vaporized water and 150.0 parts of N-methyl-N-(tetradecanoyl) glycine, start the stirrer in the stirred tank reactor, set The rotation speed is 150rpm, and the hot lubricating oil conduction heater in the stirred tank reactor is started to raise the temperature to 143.0°C;

[0109] S2: Separately take berkelium nanoparticles, and add berkelium nanoparticles to 150.0 parts of polymerized naphtha with a mass concentration of 160 ppm for dispersing berkelium nanoparticles;

[0110] S3: Add the dispersed berkelium nanoparticles into the stirred tank reactor, adjust the pH value at 6.2, keep warm and stir for 150 minutes; then stop the reaction and let stand for 7.0×10 minutes;

[0111] S4: Add 180.5 parts of (methoxymethyl) oxirane and stir evenly, carry out the reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com