High-strength tile binder

A tile adhesive and high-strength technology, which is applied in the field of adhesives and high-strength tile adhesives, can solve problems such as hollowing and low strength in use, and achieve simple and convenient use, enhanced water retention, and improved bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

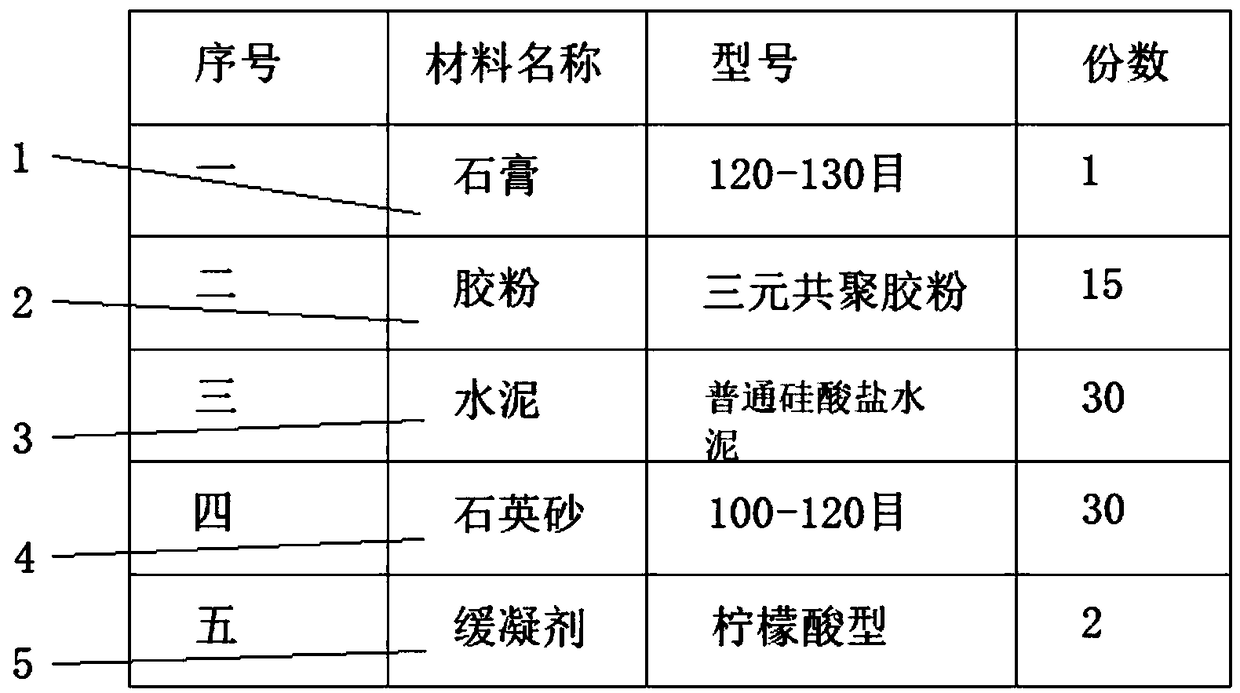

[0014] Example: such as figure 1 As shown, the present invention provides a high-strength tile adhesive, including gypsum 1, the high-strength tile adhesive includes gypsum 1, rubber powder 2, cement 3, quartz sand 4 and retarder 5, and gypsum 1 , rubber powder 2, cement 3, quartz sand 4 and retarder 5 are all fully mixed with appropriate models and appropriate parts.

[0015] In order to make this kind of high-strength ceramic tile adhesive easy to use and high in work efficiency, the gypsum 1 is β-type hemihydrate gypsum obtained by calcining at 175-180° C. The rubber powder 2 is a hydrophobic ethylene / vinyl laurate / vinyl chloride ternary copolymer powder that can be redispersed in water, the cement 3 is ordinary portland cement, and the quartz sand 4 is 100- 120 meshes of hard quartz sand, and the retarder 5 is a mixture retarder of one or more of citric acid, sodium polyphosphate, and borax. The gypsum 1, rubber powder 2, cement 3, quartz sand 4 and retarder 5 parts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com