Rock rip-rap concrete protection face structure and construction method thereof

A kind of fine stone concrete and concrete technology, which is applied in the direction of coastline protection and climate change adaptation, can solve the problems of high cost, slow construction progress and small landfill volume of cast-in-place concrete protection, so as to save the cost of surface protection engineering and protect Stability and safety, the effect of stabilizing the structure of the face armor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

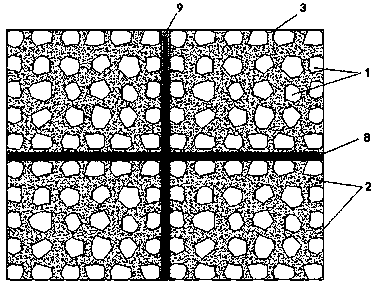

[0032] The present embodiment marble concrete face protection structure, as figure 1 As shown, it includes a number of perfusion units 3 arranged in a matrix, and a longitudinal slit 9 is provided between two adjacent horizontal perfusion units 3, and a horizontal slit 8 is provided between two adjacent vertical perfusion units 3. The splits 9 and the transverse splits 8 are vertically arranged, and the longitudinal splits 9 and the transverse splits 8 are filled with high-density low-foaming polyethylene boards.

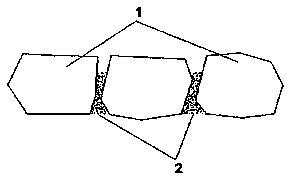

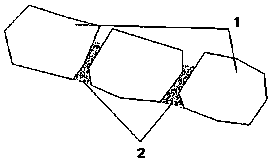

[0033] Such as figure 2 As shown in or 3, each perfusion unit 3 includes several small-volume massive rubble 1 randomly placed horizontally or obliquely, and the weight of each small-volume massive rubble 1 is not less than 25kg, and the middle thickness is not less than 15cm; There is a gap ≥ 5cm between two adjacent small-volume massive rubble 1, and C25 fine-grain concrete 2 is poured into the gap, and the pouring thickness of C25 fine-gravel concrete 2 is less...

Embodiment 2

[0035] Present embodiment is used for the construction method of large-scale enclosing sea embankment suppression platform with embodiment 1 marble concrete face protection structure, as Figure 4 As shown, the specific steps are as follows:

[0036] (1) Slope construction: Slope adjustment is carried out on the full-length mud-filled pipe bag within the scope of the surrounding seawall 4 suppression platform 5, and the bagged gravel 6 is used to build the edge of the long mud-filled pipe bag at the bottom of the outer sea side Slope, and the height ratio of the full-length mud-filled pipe bag to the slope is 1:3;

[0037] (2) Lay composite geotextile: Lay a layer of 380g / m on the long mud-filled pipe bag 2 Composite geotextile, and then lay 200mm thick bagged gravel on the geotextile for filling and leveling;

[0038] (3) Cracking: On the bagged crushed stones to be filled and leveled, the vertical joints are set every 5m, and the horizontal joints are divided every 6m. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com