A main and auxiliary spring assembly of equal cross-section blades

A main and auxiliary spring, equal-section technology, applied to leaf springs, spring assemblies composed of several springs, springs, etc., can solve the problems of short life, low fuel efficiency, and high quality of leaf springs, so as to improve life and improve Fuel efficiency, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

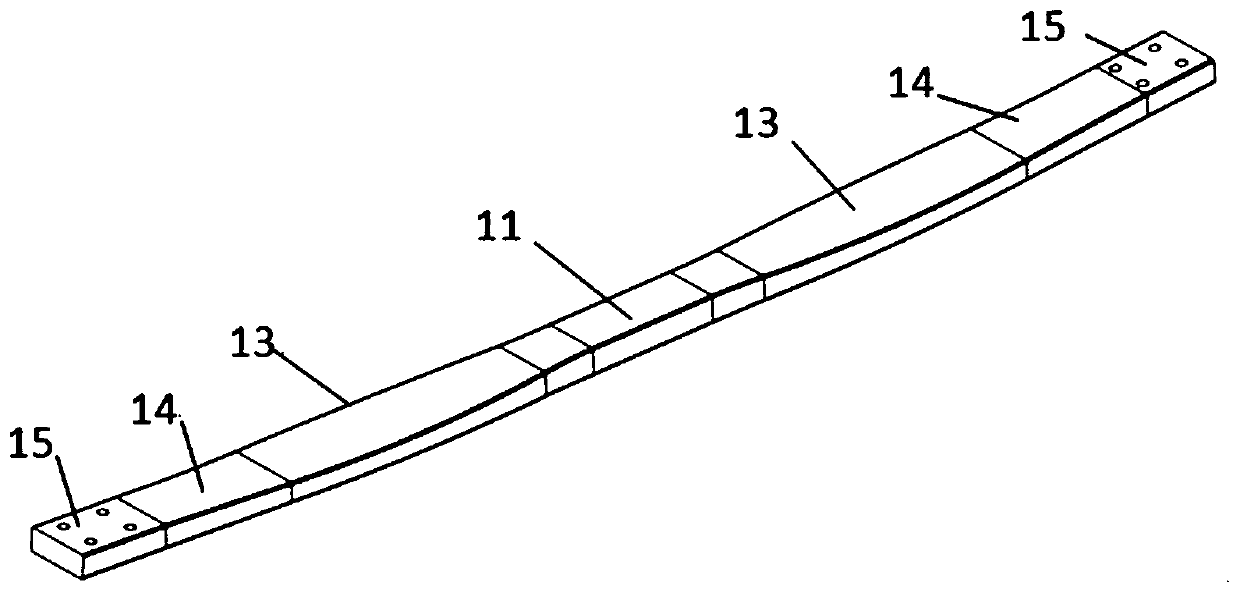

[0052] The technical solutions of the present invention will be described in detail by the following examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

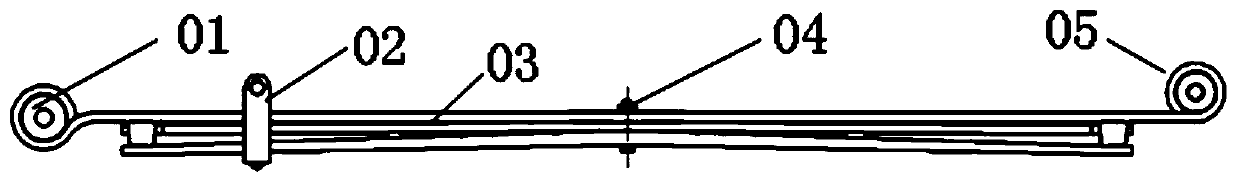

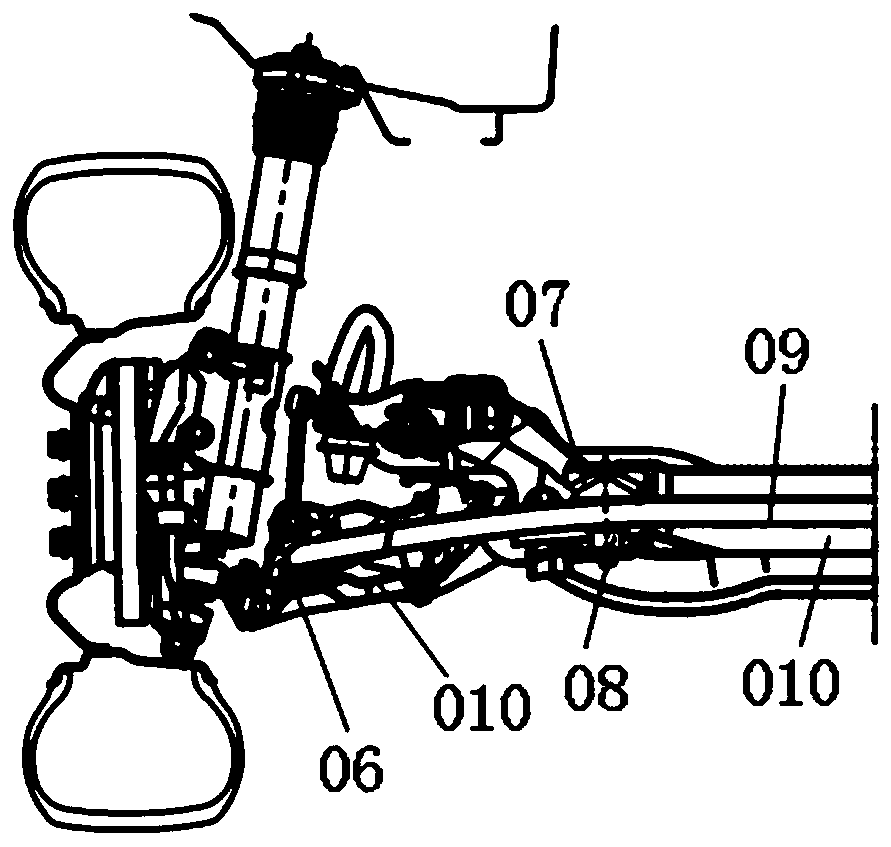

[0053] The present application provides an equal-section blade main and auxiliary spring assembly, such as Figure 3 to Figure 15 As shown, it includes FRP main spring blades, roll ears, front bushing, upper cover plate, lower backing plate, rear bushing, soft backing plate and FRP secondary spring blades.

[0054] Two ends of the FRP main spring blade are respectively fixed with a roll ear; the front bushing and the rear bush are respectively arranged in the roll ear.

[0055] The FRP auxiliary spring blade is arranged on the FRP main spring blade, and is fixedly connected through the upper cover plate and the lower backing plate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com