Mixed multi-stage fermentation fish sauce and processing method thereof

A technology of multi-stage fermentation and processing method, applied in food science and other directions, can solve problems such as loss of amino nitrogen content, reduction, and reduction of salty taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

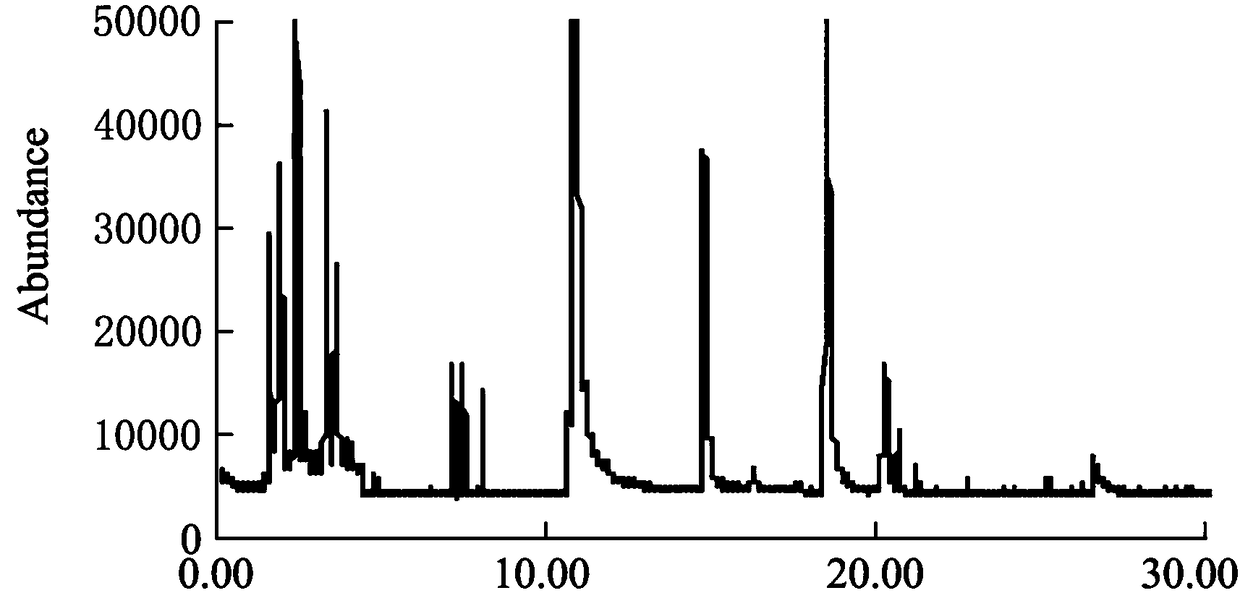

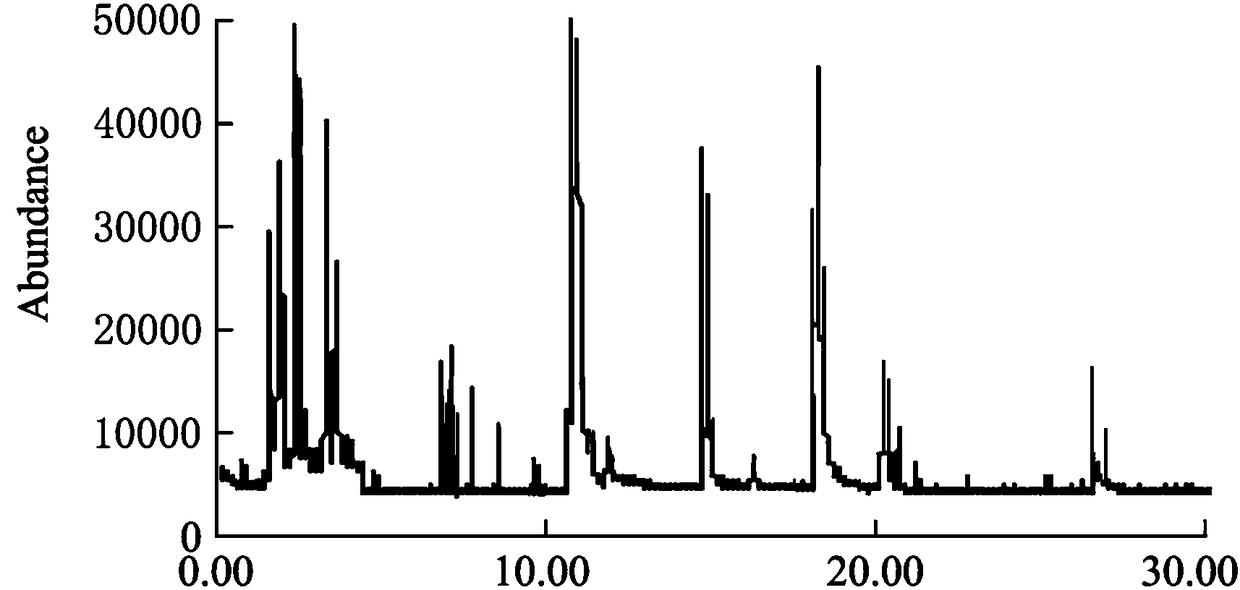

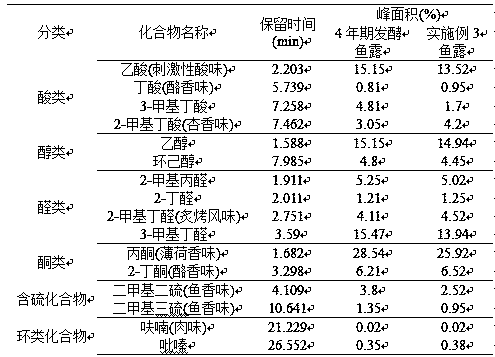

Image

Examples

Embodiment 1

[0033] The processing method of the fish sauce of mixed multistage fermentation in the present embodiment, comprises the following steps:

[0034] a) Mix and marinate a variety of fresh marine fish raw materials with salt. The weight ratio of sea fish and salt is 3.5:1, mix and place in the fermentation tank, seal with salt, and salt and ferment at room temperature to form an autolyzed state Carry out a period of pre-fermentation for 2 months;

[0035] b) Mix fresh sea fish head and viscera into a slurry, mix with about 20% of fish mash that has been fermented to an autolyzed state in the early stage, mix it at a ratio of 10:80-85, and add other ingredients to the mixed material 3% by weight of neutral protease with an enzyme activity of 50,000-80,000U, after mixing, carry out secondary mixed fermentation at room temperature for 1-2 weeks to form a protein solution;

[0036] The protein solution, the new block fresh sea fish raw material, and the rest of the pre-fermented fis...

Embodiment 2

[0042] The processing method of the fish sauce of mixed multistage fermentation in the present embodiment, comprises the following steps:

[0043] a) Mix and marinate the raw materials of anchovies and small miscellaneous fish with salt, mix sea fish and salt in a weight ratio of 3.2:1 and place them in a fermentation tank, seal them with salt, and salt them and ferment them at room temperature to form a natural 2 months of pre-fermentation in the dissolved state;

[0044] b) Fresh marine fish heads and viscera are mixed and beaten into a slurry, mixed with about 30%-35% of a period of fish mash that has been fermented to an autolyzed state in the early stage, and mixed in a ratio of 11-13:80-90, and then poured into Add 5 / 1000 of its weight neutral protease with enzyme activity of 80000-100000U to the mixed material, after mixing, carry out secondary mixed fermentation at room temperature for 1-2 weeks to form protein solution;

[0045] The protein solution, new 1-3cm 3 The...

Embodiment 3

[0051] The processing method of the fish sauce of mixed multistage fermentation in the present embodiment, comprises the following steps:

[0052] a) Mix and marinate the raw materials of anchovies and blue scads with salt, mix sea fish and salt at a weight ratio of 3:1 and place them in a fermentation tank, seal them with salt, and salt them and ferment them at room temperature to form a natural 2-2.5 months of pre-fermentation in the dissolved state;

[0053] b) Mix the head and viscera of fresh marine fish into a slurry, and mix it with about 20%-30% of a period of fish mash that has been fermented to an autolyzed state in the early stage, and mix it in a ratio of 12-15:85-95, and then pour it into the mixed Add 5 / 1000 of its weight neutral protease with enzyme activity of 80000-100000U to the material, mix and carry out secondary mixed fermentation at room temperature for 1-2 weeks to form protein solution;

[0054] Grind the protein solution and the new one to 0.3-1cm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com