Waste tire treatment tail gas purification system

A technology for exhaust gas purification and waste tires, applied in gas treatment, chemical/physical/physicochemical processes, chemical instruments and methods, etc., to achieve the effect of slowing down the wind speed and good defogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

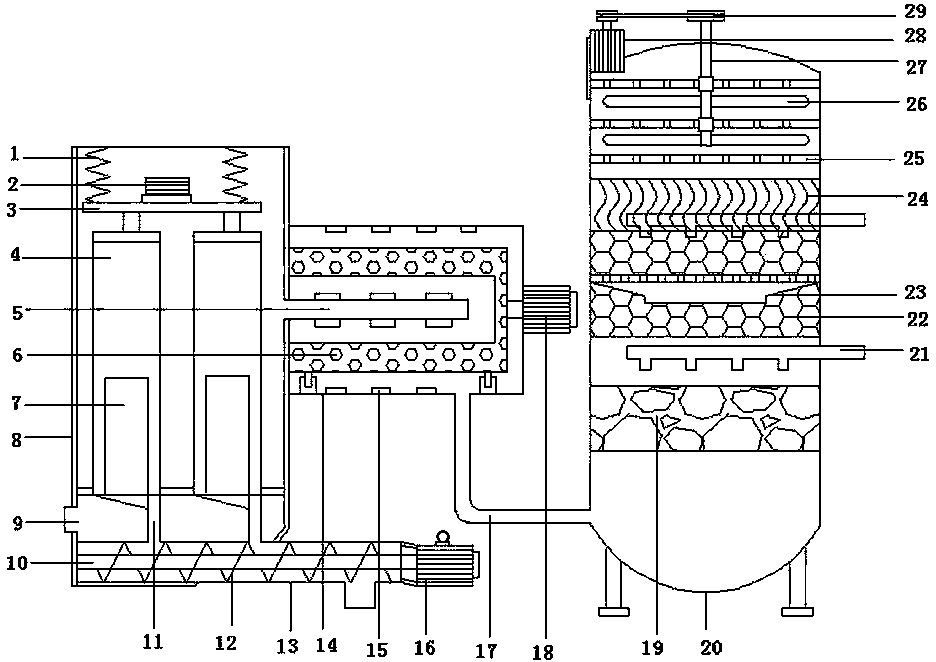

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] A waste tire treatment tail gas purification system, comprising a dust collector 8, a purifier 14, and a desulfurization tower 20, characterized in that the dust collector 8 is a hollow cuboid structure, a spring 1 is arranged on the top of the dust collector 8, and the other end of the spring 1 is arranged There is a mounting plate 3, a polarizing motor 2 is installed at the center of the upper surface of the mounting plate 3, a number of cloth bags 4 are arranged on the lower surface of the mounting plate 3, an inner pipe 7 is arranged at the lower part of the cloth bag 4, and an air inlet 9 is arranged at the lower left side of the dust collector 8 A conveyor 13 is provided at the bottom of the dust remover 8, a first motor 16 is provided at the center of the right end of the conveyor 13, a first rotating shaft 10 is provided on the left side of the first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com