Pressure sensor, manufacturing method of pressure sensor, pressure sensor module, electronic apparatus, and vehicle

A technology of a pressure sensor and a manufacturing method, applied in the field of moving objects, can solve the problems of different measurement values, hysteresis, and reduced pressure detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0051] First, the pressure sensor according to the first embodiment of the present invention will be described.

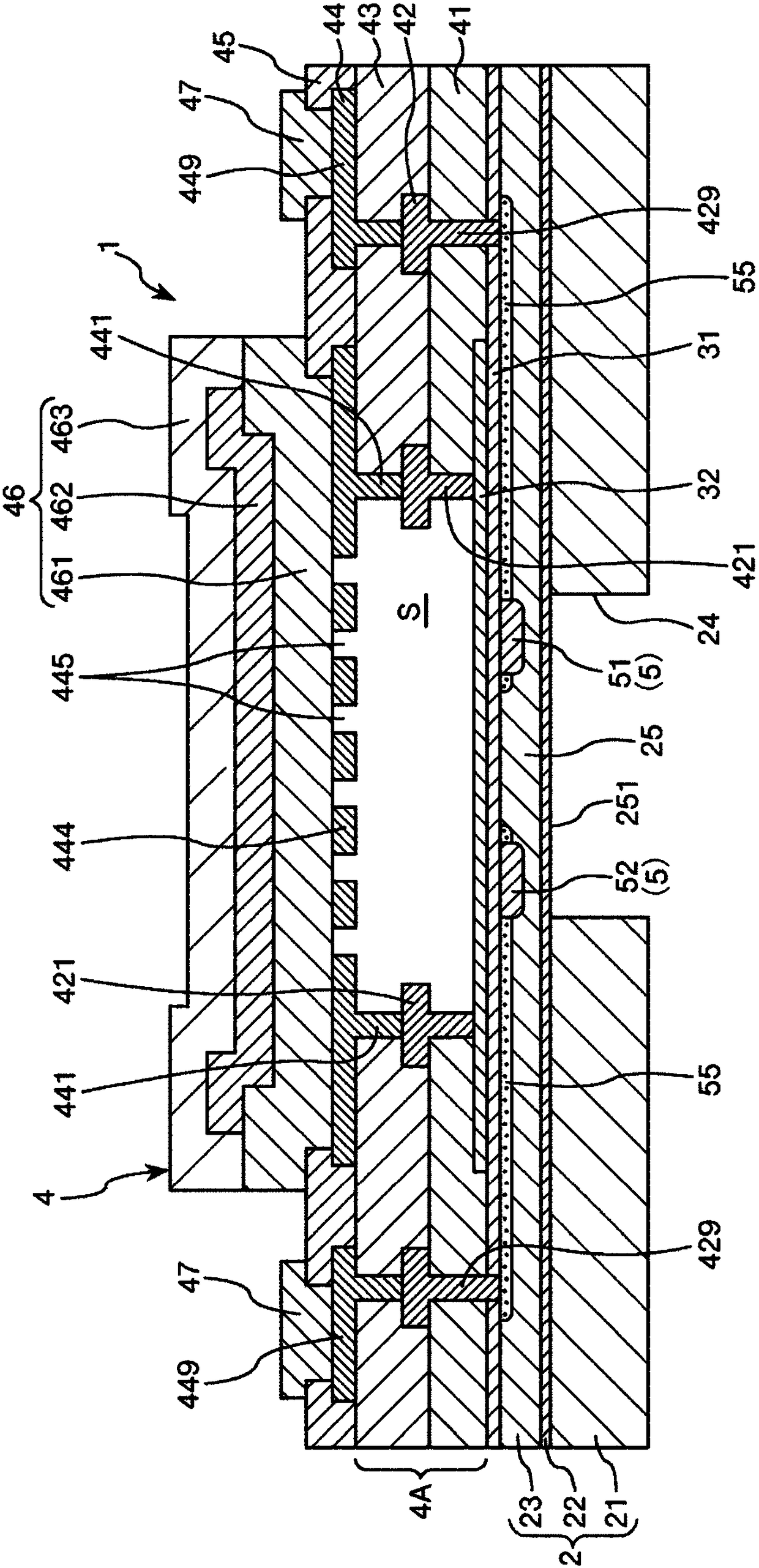

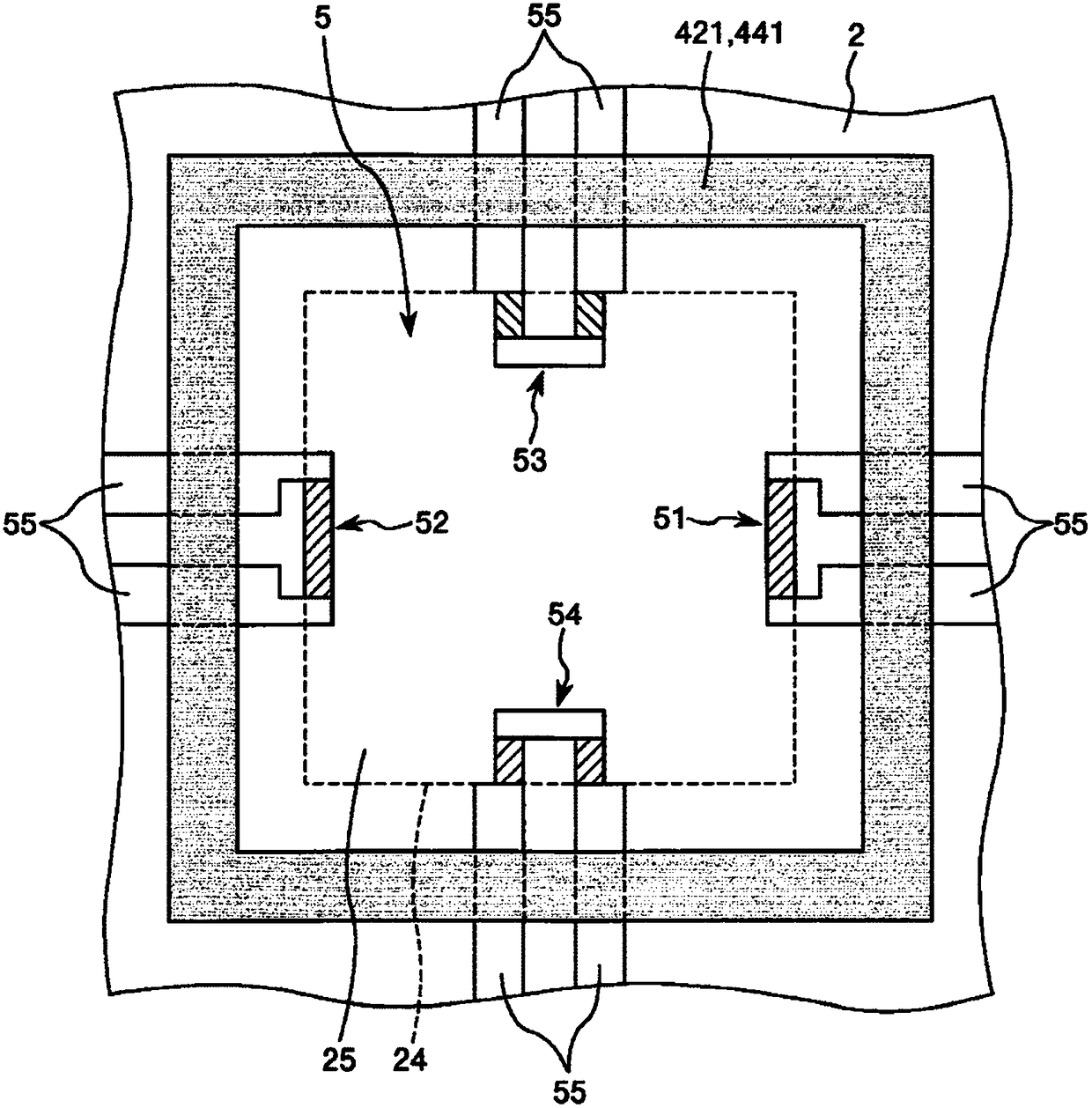

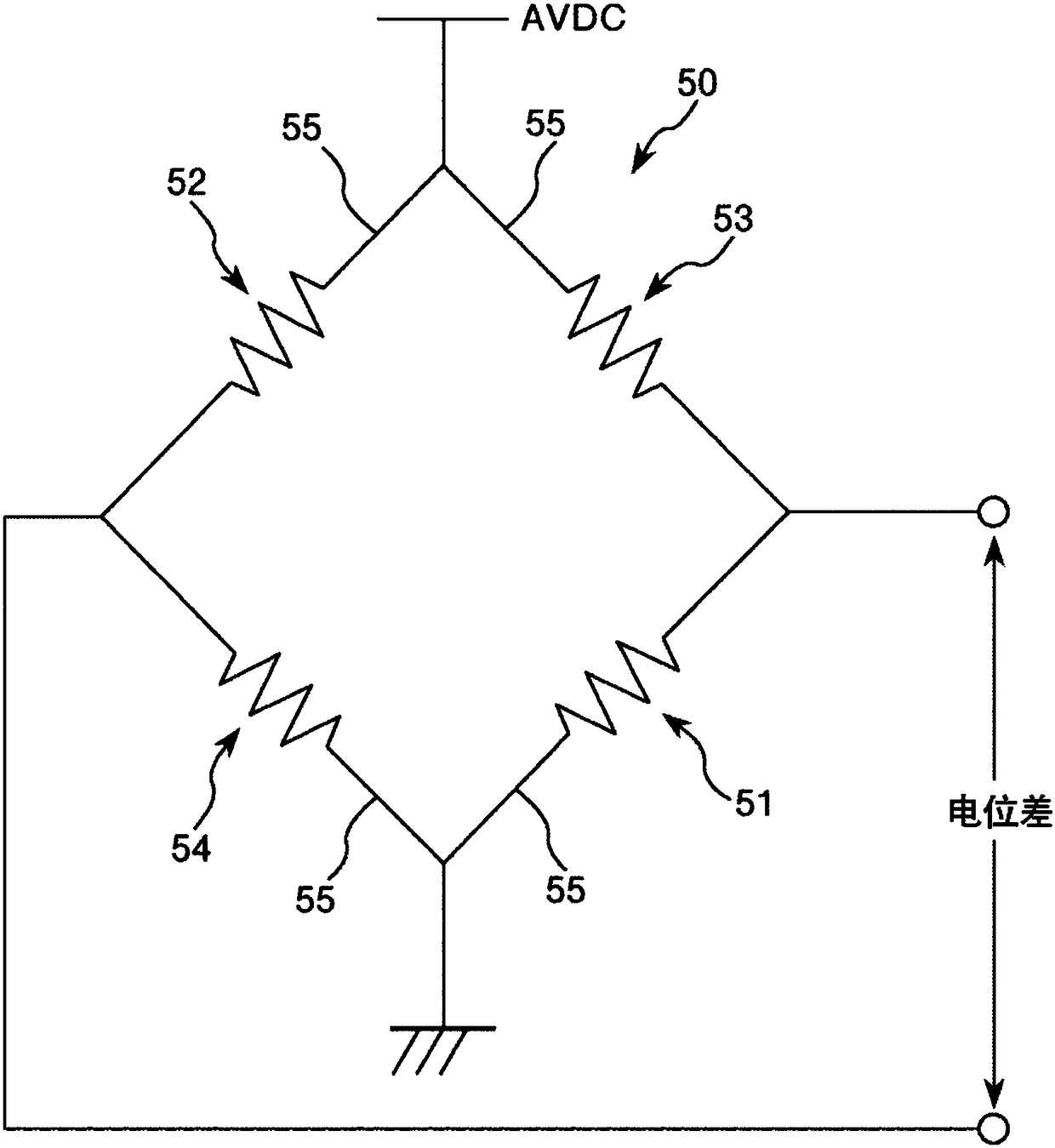

[0052] figure 1 It is a cross-sectional view of the pressure sensor according to the first embodiment of the present invention. figure 2 Yes means figure 1 A plan view of the pressure sensor part of the pressure sensor shown. image 3 Yes means include figure 2 The diagram of the bridge circuit including the pressure sensor section shown. Figure 4 Yes figure 1 An enlarged cross-sectional view of the sealing layer of the pressure sensor shown. Figure 5 as well as Image 6 Respectively means figure 1 A cross-sectional view of a modified example of the pressure sensor shown. Figure 7 It is a graph showing the stress change of the silicon oxide film due to moisture adsorption. Picture 8 Yes means figure 1 The flow chart of the manufacturing process of the pressure sensor shown. Figure 9 to Figure 17 Are used to figure 1 A cross-sectional view explaining the manufactu...

no. 2 approach

[0107] Next, the pressure sensor module according to the second embodiment of the present invention will be described.

[0108] Figure 18 It is a cross-sectional view of the pressure sensor module according to the second embodiment of the present invention. Figure 19 Yes Figure 18 A plan view of the supporting substrate included in the pressure sensor module shown.

[0109] Hereinafter, the pressure sensor module of the second embodiment will be described centering on the differences from the above-mentioned embodiment, and description of the same matters will be omitted.

[0110] Such as Figure 18 As shown, the pressure sensor module 100 has a package 110, a support substrate 120, a circuit element 130, a pressure sensor 1, and a filling part 140. The package 110 has an internal space S1, and the support substrate 120 is configured to be drawn out from the internal space S1 To the outside of the package 110, the circuit element 130 and the pressure sensor 1 are supported by the ...

no. 3 approach

[0123] Next, the electronic device according to the third embodiment of the present invention will be described.

[0124] Figure 20 It is a perspective view showing an altimeter as an electronic device according to the third embodiment of the present invention.

[0125] Such as Figure 20 As shown, the altimeter 200 as an electronic device can be worn on the wrist like a watch. In addition, the pressure sensor 1 (pressure sensor module 100) is mounted inside the altimeter 200, and the display unit 201 can display the altitude from the altitude of the current position, the atmospheric pressure of the current position, and the like. In addition, the display unit 201 can display various information such as the current time, the user's heart rate, and the weather.

[0126] An altimeter 200 as an example of such an electronic device has a pressure sensor 1. Therefore, the altimeter 200 can enjoy the effects of the pressure sensor 1 described above, and can exhibit high reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com