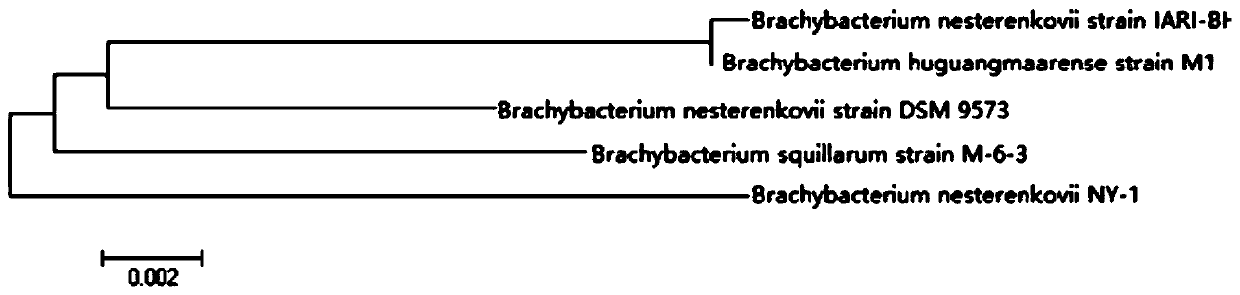

A bacterial agent comprising Brevibacterium nirzia

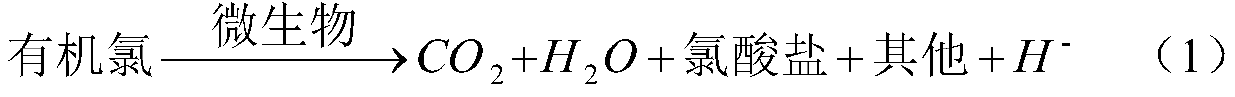

A technology of Brevibacterium nissleri and bacterial agents, applied in the field of bacterial agents containing Brevibacterium nierlii NY-1, which can solve the problems of low treatment efficiency of volatile organic chlorine, uneven loading, and packing collapse, etc. Lightweight, shortened start-up period, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: A bacterial agent for purifying exhaust gas containing organic chlorine and its application

[0043] The present invention also provides an inoculum prepared from Brevibacterium niersii NY-1, which can be used to purify exhaust gas containing organic chlorine and solve the problem of volatile organic chlorine pollution generated in processes such as pesticide wastewater treatment. The preparation method of the agent is as follows:

[0044] (1) Preparation method of fermentation broth

[0045] Brevibacterium niersii NY-1 was cultured on a slope and then connected to the liquid fermentation medium, and then scaled up and cultivated step by step according to the 10% inoculum. The fermentation and culture conditions were: 36°C, ventilation 10-100L / min, dissolved oxygen> Under the condition of 2.0mg / L, tank pressure 0.03-0.10Mpa, culture time is 48h;

[0046] The composition of the culture medium for slant culture is: glucose 0.5g, KH 2 PO 4 2.0g, NaHCO 3 2.0g, KNO 3 2....

Embodiment 2

[0053] Example 2: A bacterial agent for purifying exhaust gas containing organic chlorine and its application

[0054] The present invention also provides an inoculum prepared from Brevibacterium niersii NY-1, which can be used to purify exhaust gas containing organic chlorine and solve the problem of volatile organic chlorine pollution generated in processes such as pesticide wastewater treatment. The preparation method of the agent is as follows:

[0055] (1) Preparation method of fermentation broth

[0056] Brevibacterium niersii NY-1 was cultured on a slope, and 25% of the inoculum was inserted into the liquid fermentation medium for gradual amplification. The fermentation and culture conditions were: 36°C, ventilation 10-100L / min, dissolved oxygen > Under the condition of 2.0mg / L, tank pressure 0.03-0.10Mpa, culture time 72h;

[0057] The composition of the culture medium for slant culture is: glucose 0.5g, KH 2 PO 4 2.0g, NaHCO 3 2.0g, KNO 3 2.0g, NH 4 Cl 0.5g, MgCl 2 ·6H 2 O...

Embodiment 3

[0064] Example 3: A bacterial agent for purifying exhaust gas containing organic chlorine and its application

[0065] The present invention also provides an inoculum prepared from Brevibacterium niersii NY-1, which can be used to purify exhaust gas containing organic chlorine and solve the problem of volatile organic chlorine pollution generated in processes such as pesticide wastewater treatment. The preparation method of the agent is as follows:

[0066] (1) Preparation method of fermentation broth

[0067] Brevibacterium niersii NY-1 was cultured on an inclined plane and then connected to the liquid fermentation medium. The culture was amplified step by step according to the 15% inoculum. The fermentation and culture conditions were: 36℃, ventilation 10-100L / min, dissolved oxygen> Under the condition of 2.0mg / L, tank pressure 0.03-0.10Mpa, culture time is 24h;

[0068] The composition of the culture medium for slant culture is: glucose 0.5g, KH 2 PO 4 2.0g, NaHCO 3 2.0g, KNO 3 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com