Heat treatment method for improving residual austenite morphology and improving TRIP steel mechanical property

A heat treatment method and morphology technology, applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problem of not being reached, and achieve the effect of fast heating rate, short heat treatment cycle, high strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

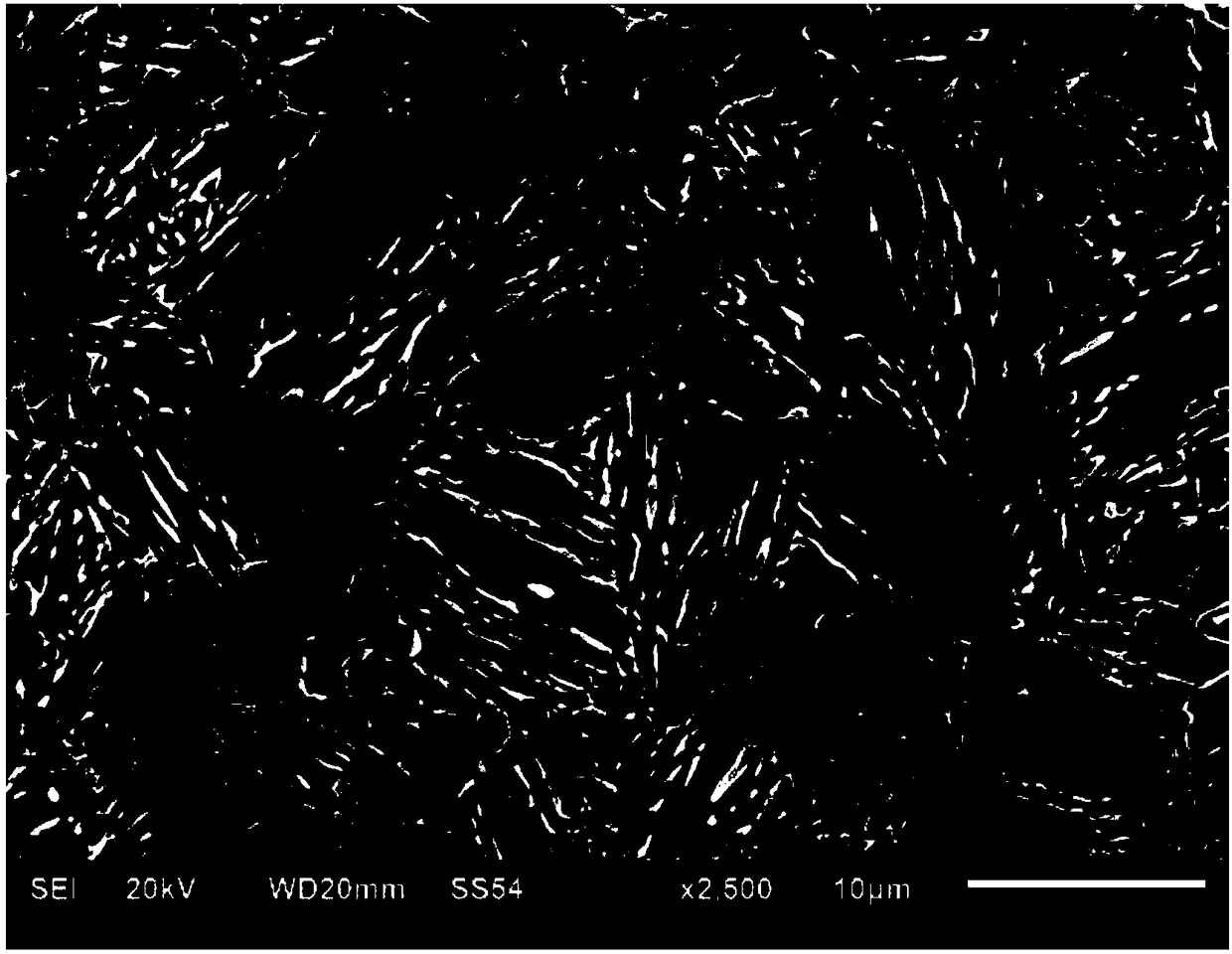

Embodiment 1

[0033] A heat treatment method for improving the para-austic morphology and improving the mechanical properties of TRIP steel, comprising the following steps:

[0034] Step 1: Austenitizing pretreatment system

[0035] Select fully cleaned TRIP780 cold-rolled sheet as the initial material, put it in a salt bath, perform austenitizing pretreatment, and then water quench to obtain austenitizing pretreated steel plate; among them, the temperature of austenitizing pretreatment The temperature is 925℃, and the time of austenitizing pretreatment is 90s;

[0036] The fully cleaned TRIP780 cold-rolled steel plate is a standard tensile test sample with a gauge length of 50mm made from a 1.2mm thick TRIP780 cold-rolled steel plate according to GB / T228-2010.

[0037] The cleaning steps for the fully cleaned TRIP780 cold-rolled sheet are: first use acetone to remove rust and oil, and then use alcohol to clean it to avoid uneven heating during heat treatment.

[0038] Step 2: Transition ...

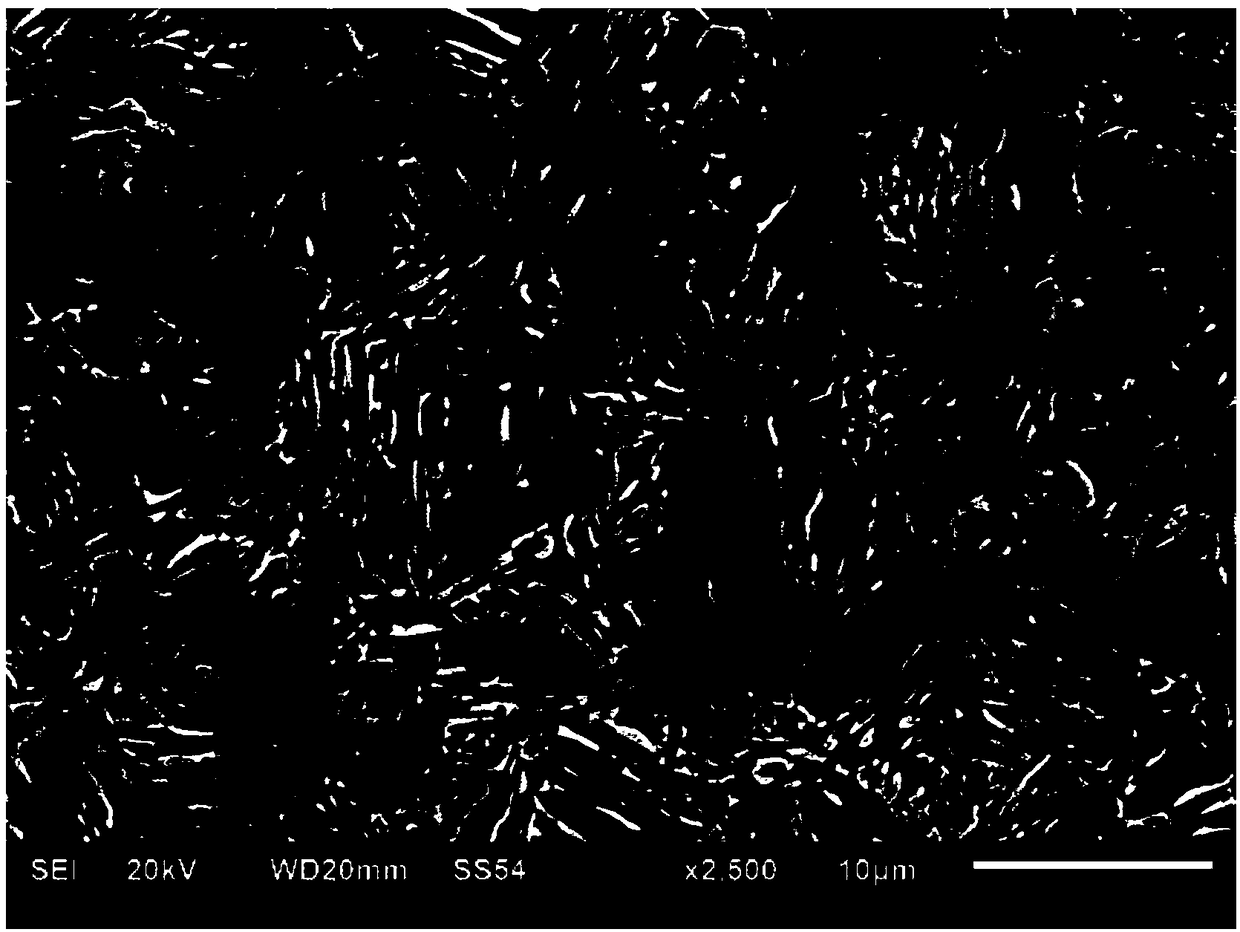

Embodiment 2

[0048] A heat treatment method for improving the para-austic morphology and improving the mechanical properties of TRIP steel, comprising the following steps:

[0049] Step 1: Austenitizing pretreatment system

[0050] Select fully cleaned TRIP780 cold-rolled sheet as the initial material, put it in a salt bath, perform austenitizing pretreatment, and then water quench to obtain austenitizing pretreated steel plate; among them, the temperature of austenitizing pretreatment The temperature is 925℃, and the time of austenitizing pretreatment is 90s;

[0051] The fully cleaned TRIP780 cold-rolled steel plate is a standard tensile test sample with a gauge length of 50mm made from a 1.2mm thick TRIP780 cold-rolled steel plate according to GB / T228-2010.

[0052] The cleaning steps for the fully cleaned TRIP780 cold-rolled sheet are: first use acetone to remove rust and oil, and then use alcohol to clean it to avoid uneven heating during heat treatment.

[0053] Step 2: Transition ...

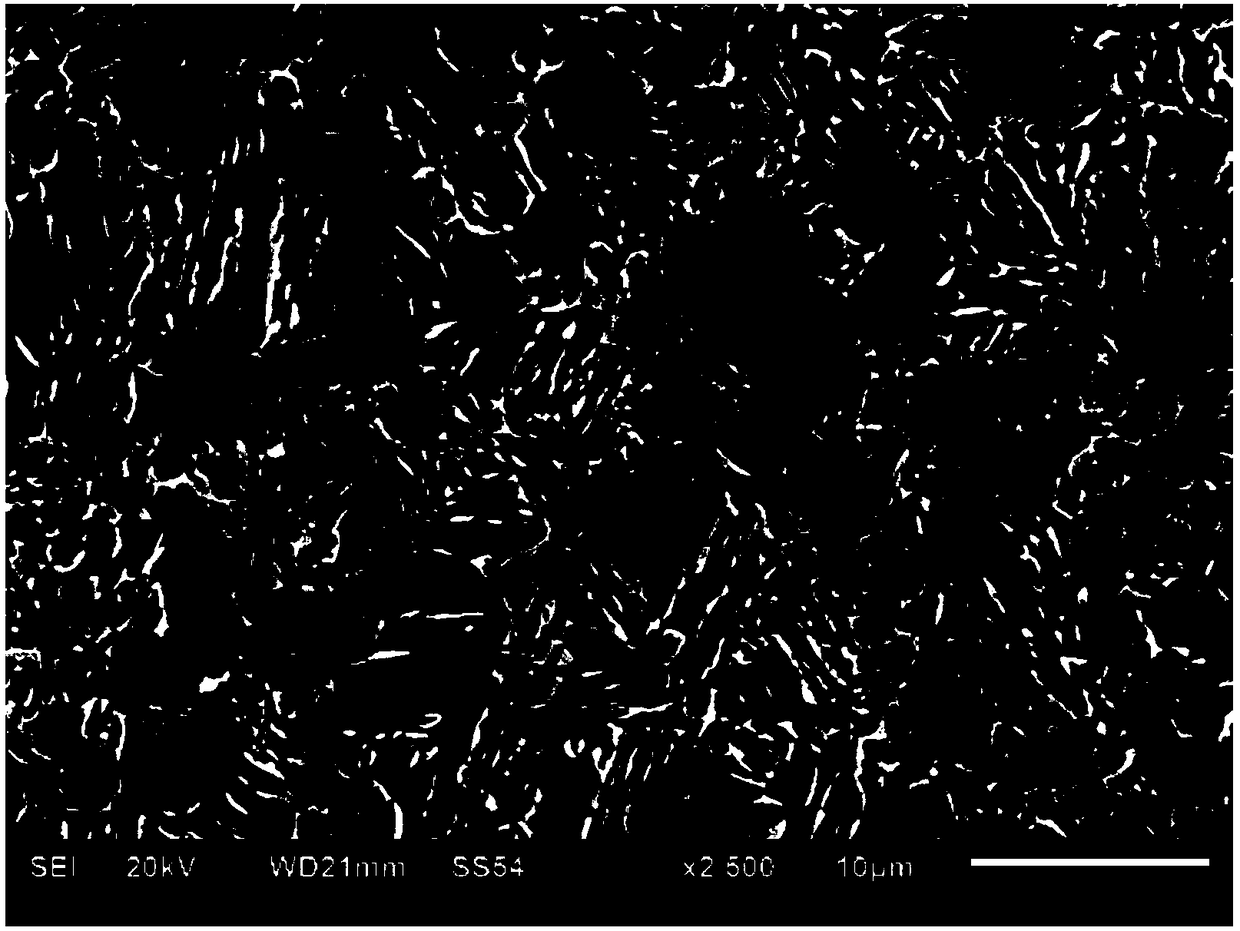

Embodiment 3

[0063] A heat treatment method for improving the para-austic morphology and improving the mechanical properties of TRIP steel, comprising the following steps:

[0064] Step 1: Austenitizing pretreatment system

[0065] Select fully cleaned TRIP780 cold-rolled sheet as the initial material, put it in a salt bath, perform austenitizing pretreatment, and then water quench to obtain austenitizing pretreated steel plate; among them, the temperature of austenitizing pretreatment The temperature is 925℃, and the time of austenitizing pretreatment is 90s;

[0066] The fully cleaned TRIP780 cold-rolled steel plate is a standard tensile test sample with a gauge length of 50mm made from a 1.2mm thick TRIP780 cold-rolled steel plate according to GB / T228-2010.

[0067] The cleaning steps for the fully cleaned TRIP780 cold-rolled sheet are: first use acetone to remove rust and oil, and then use alcohol to clean it to avoid uneven heating during heat treatment.

[0068] Step 2: Transition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com