Printing method of rayon elastic fabric

A printing method and elastic fabric technology, which is applied in the dyeing method, fabric elongation, textile material processing, etc., can solve problems such as easy curling, achieve printing effect, good permeability, and improve pilling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

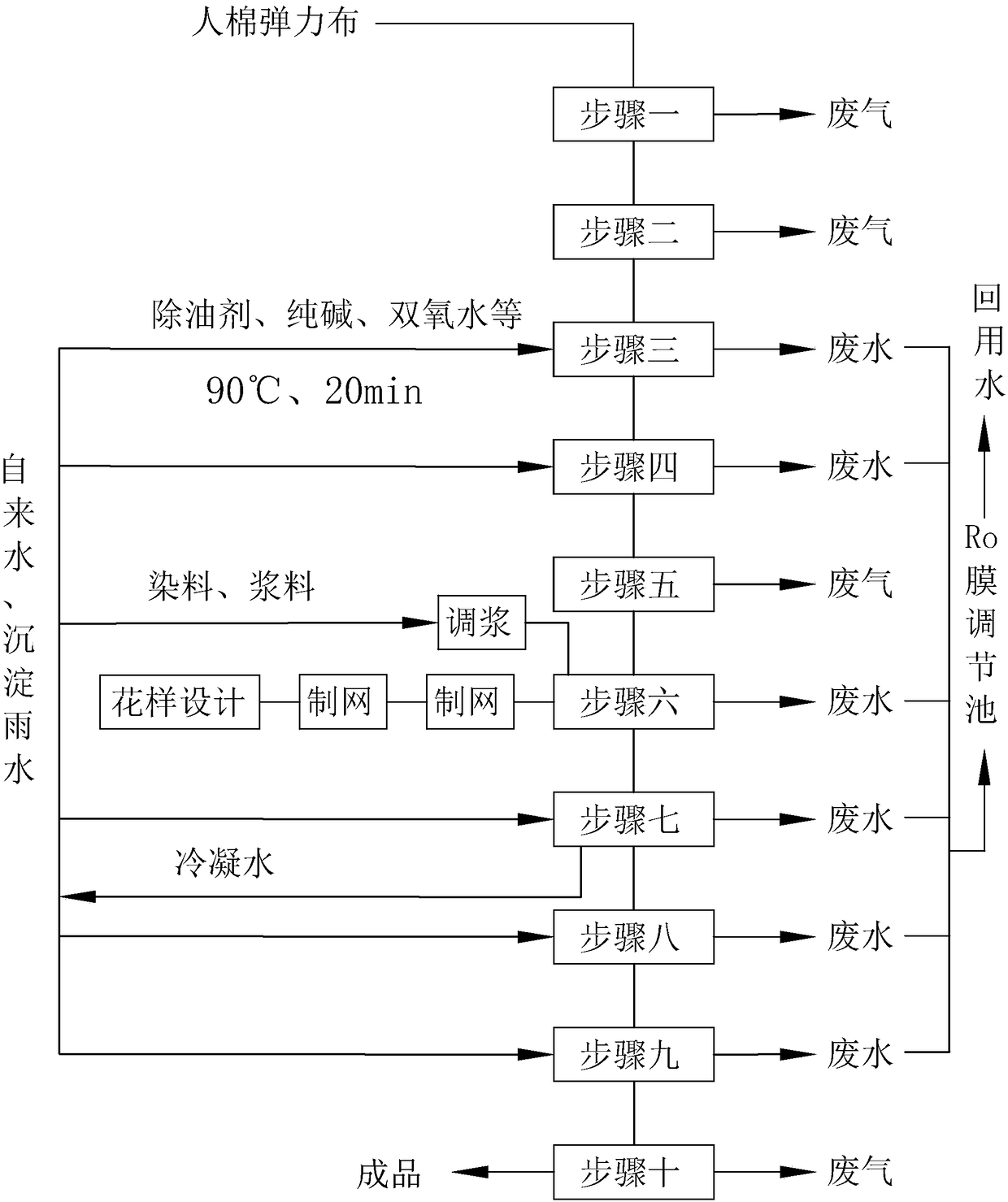

[0030] A printing method for rayon elastic cloth, comprising the following steps;

[0031] Step 1: Pass the rayon elastic cloth through the gas singeing machine in open width;

[0032] Step 2: Using a sizing machine to pre-size the rayon elastic cloth treated in step 1;

[0033] Step 3: Pre-printing the rayon elastic fabric treated in step 2 to remove the oil agent, size and dirt adsorbed and contaminated during the weaving, storage and transportation process on the rayon elastic fabric;

[0034] Step 4: remove the cotton wool produced by the rayon elastic fabric treated in step 3;

[0035] Step 5: Use a sizing machine to pre-set the rayon elastic fabric treated in step 4 again;

[0036] Step 6: Design the pattern according to the drawing, then draw the draft, then make the screen with the rotary screen, and finally use the rotary screen printing machine with different patterns and color pastes to process the rayon elastic fabric treated in step 5. printing;

[0037] Step ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap