Laminated glass curtain wall

A technology of laminated glass and curtain wall, applied in the direction of walls, building components, building insulation materials, etc., can solve the problems of lack of ventilation, poor fixation, high heating and cooling energy consumption, and achieve the ability to reduce sunlight transmission and block heat. Strong and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

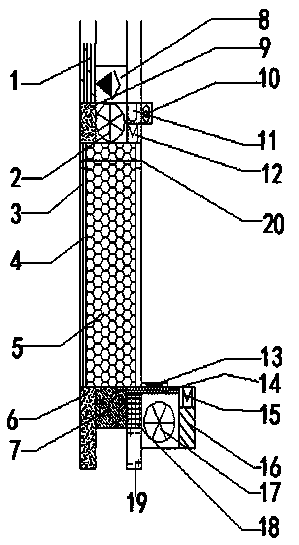

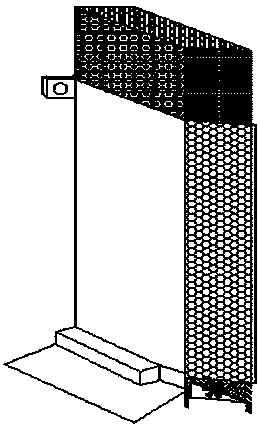

[0017] Such as Figure 1-2 Shown, a kind of laminated glass curtain wall comprises PVB encapsulation film double-layer vacuum glass 4, and described PVB encapsulation film double-layer vacuum glass 4 is coated with TIO2 inorganic film material 3, and described TIO2 inorganic film material 3 is provided with magnetic suction bar 20 , above the magnetic suction strip 20 is fixed with an embedded isolated dust-proof net 9, and above the embedded isolated dust-proof net 9 is fixed a longitudinal transverse channel steel 1, one side of the longitudinal transverse channel steel 1 and a fire alarm 8 connection, the fire alarm 8 is connected to the first fan 2, the first fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com