Parameter adjustment method of system for supplying and recovering two types of steam in iron and steel enterprise

A steam system and parameter adjustment technology, which is applied in steam generation method, steam generation method using heat carrier, steam superheating, etc., can solve the problems such as difficult to realize waste heat steam supply and recovery, unable to guarantee pressure stability, pressure fluctuation, etc. Achieve the effects of improving stability and adaptability, improving efficiency, and increasing steam recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

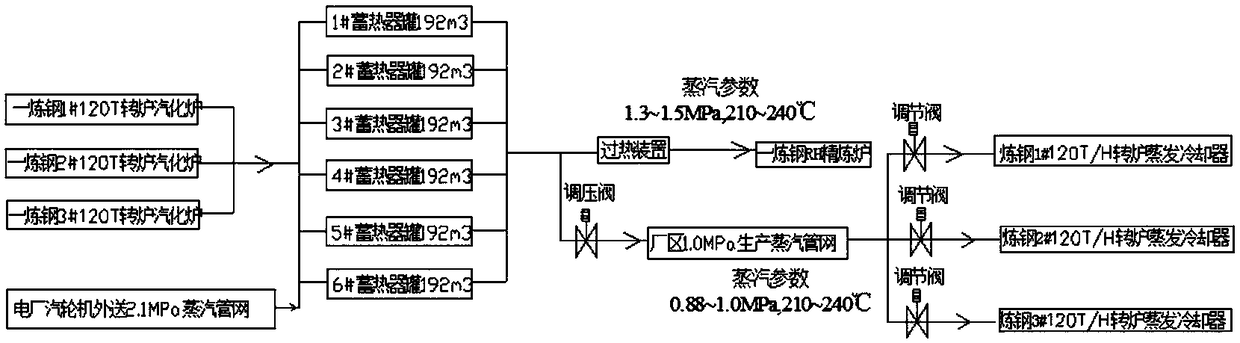

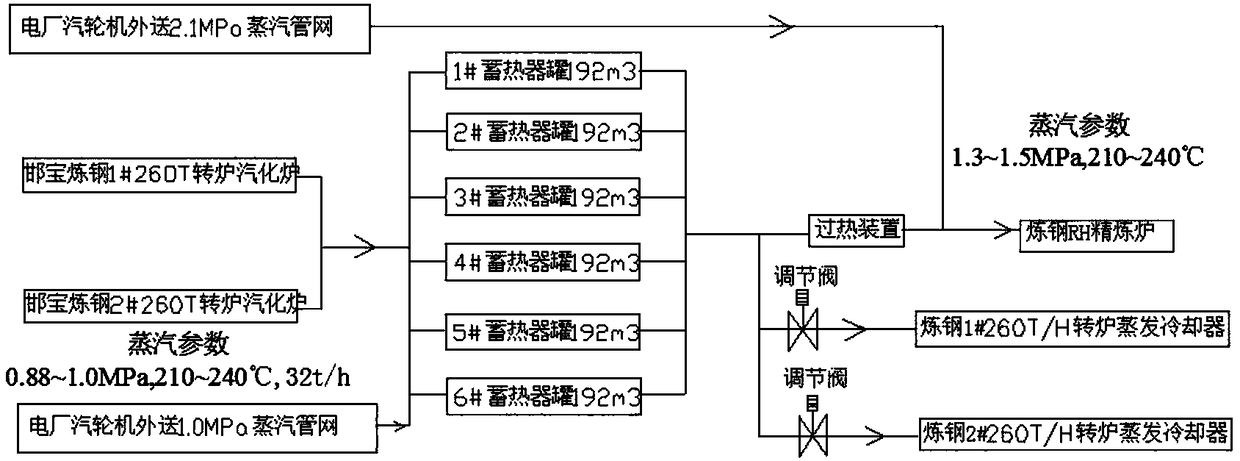

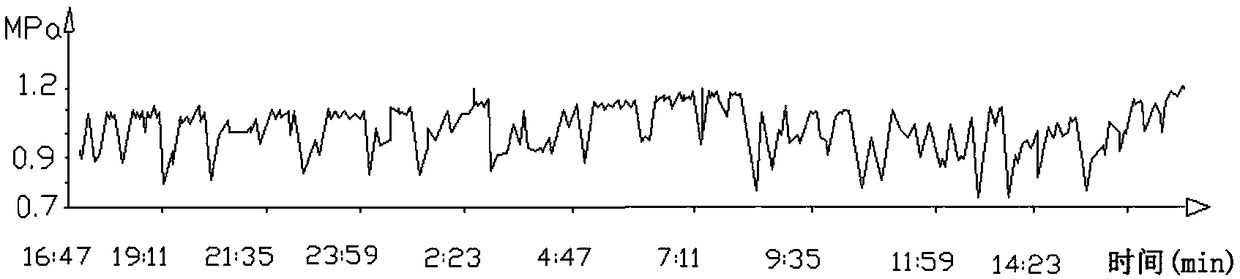

[0017] In the embodiment, in the prior art, three steam turbines in a self-provided power plant supply steam with two parameters: the first pressure is 0.95MPa and the temperature is 260°C; the second is 2.1MPa and the temperature is 290°C; sintering waste heat power generation supplies a The steam pressure of two parameters is 1.2MPa and the temperature is 260°C; the steam extraction of CDQ power generation steam turbine supplies a steam pressure of 0.5MPa and a temperature of 220°C; the steelmaking converter of Example 1 (a steelmaking converter) and Example 2 The steelmaking converter (Hanbao converter) produces steam by itself, supplying a parameter of steam pressure of 1.3MPa and temperature of 260°C. The above four steam sources supply ironmaking, steelmaking, steel rolling and other production and domestic steam through three steam pipe networks of 2.1 MPa, 1.0MPa an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com