Burner and heat treatment facility

A heat treatment and burner technology, applied in the field of burner devices and heat treatment equipment, can solve the problems of unstable air flow, difficult combustion of mixed gas, difficulty in flame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, the burner apparatus and heat treatment facility which concerns on embodiment of this invention are demonstrated concretely based on drawing. In addition, the burner device and the heat treatment facility of the present invention are not limited to the devices and facilities shown in the following embodiments, and can be appropriately changed and implemented within the range not changing the idea of the invention.

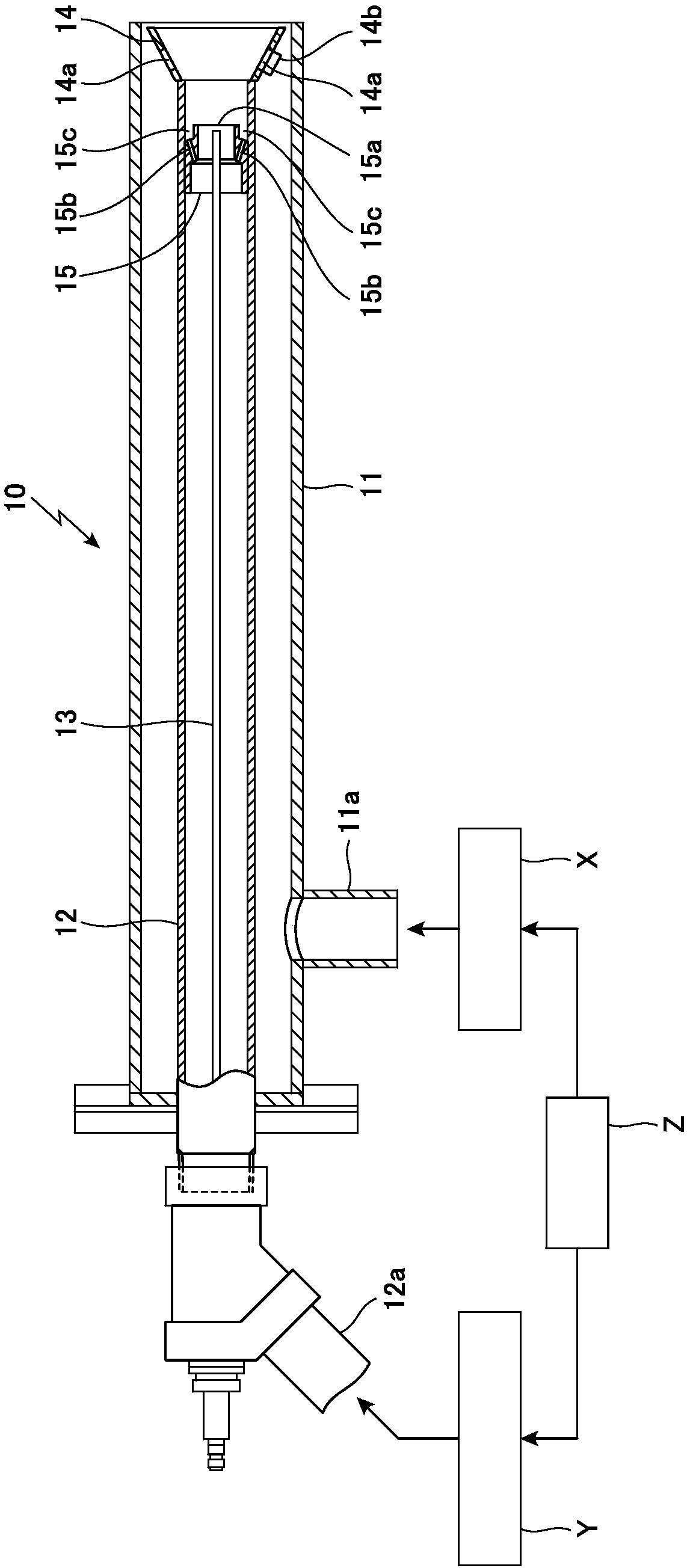

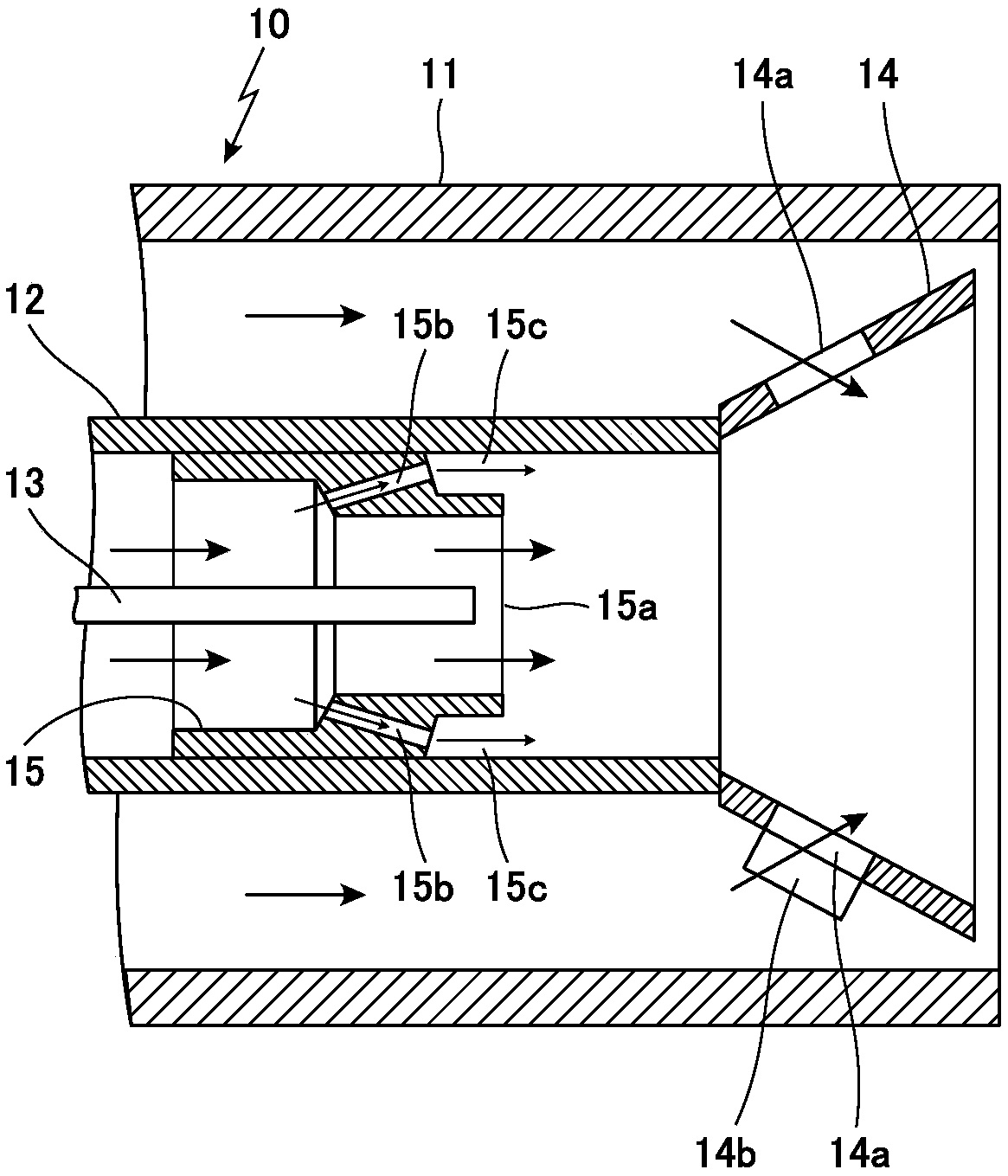

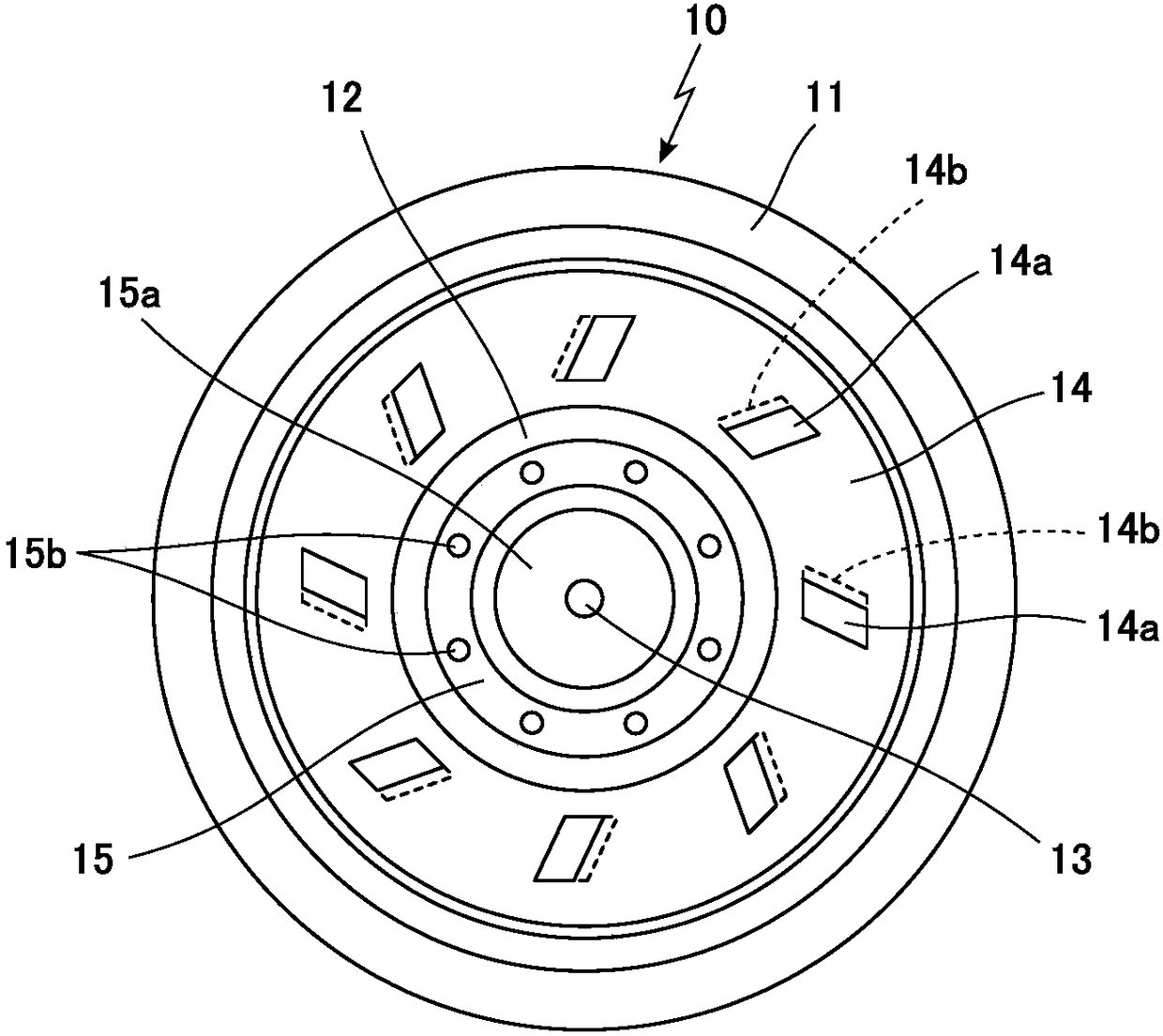

[0068] In the burner device 10 of the present embodiment, as figure 1 As shown, air is supplied from the air introduction part 11a into the air supply pipe 11 by the air supply device X, and fuel gas is supplied from the fuel gas introduction part 12a to the air supply pipe 11 arranged by the fuel gas supply device Y. In the fuel gas supply pipe 12 on the inner peripheral side, the amount of air supplied to the air supply pipe 11 by the above-mentioned air supply device X and the amount of fuel supplied to the fuel gas supply pipe 12 by the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com