Kitchen equipment linking noise reduction system and visual inspection system and linkage method thereof

A noise reduction system and visual detection technology, applied in mechanical equipment, lighting and heating equipment, heating methods, etc., can solve problems such as false alarms, false alarms, and inability to recognize smoke on the stove, and achieve instant/timely noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

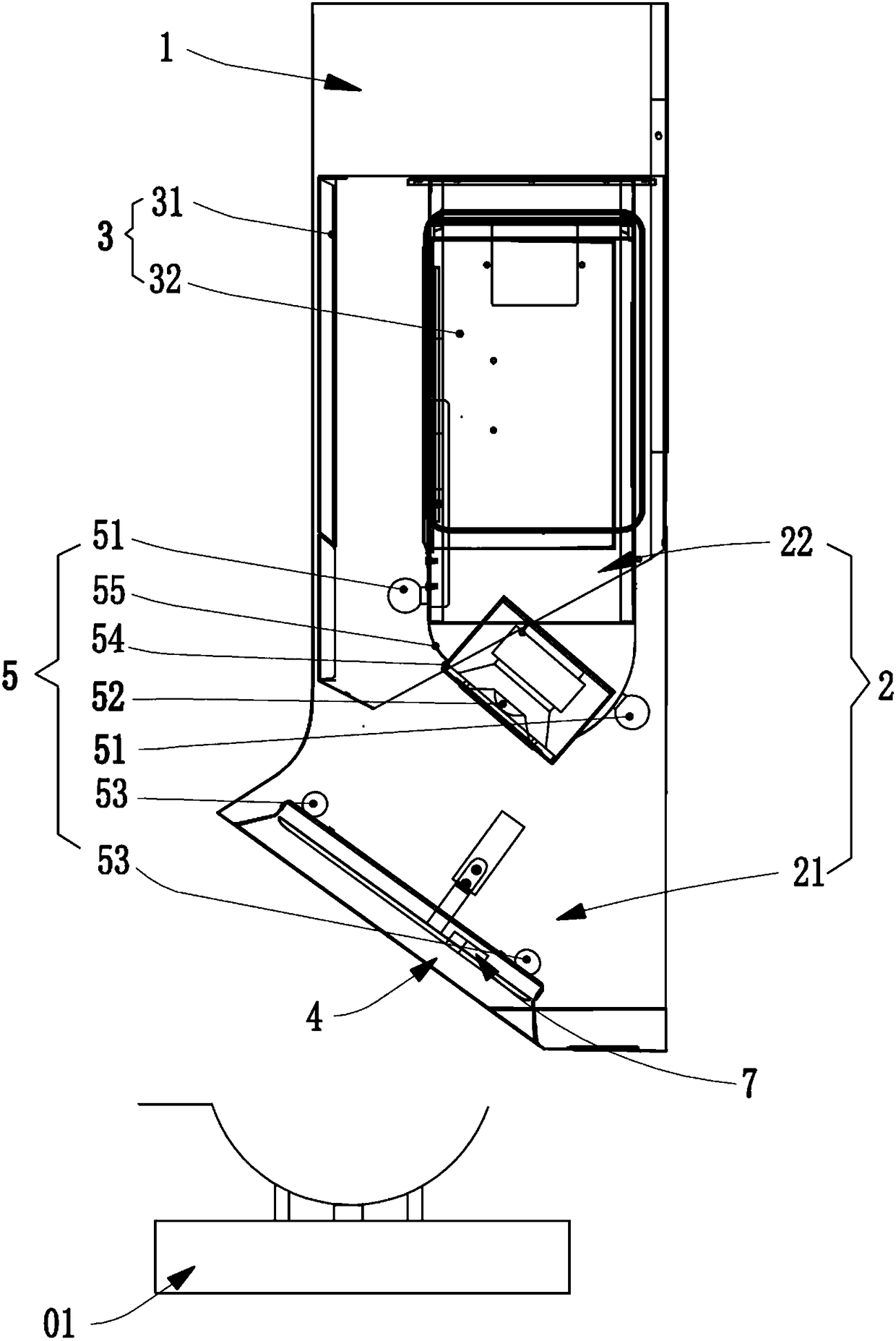

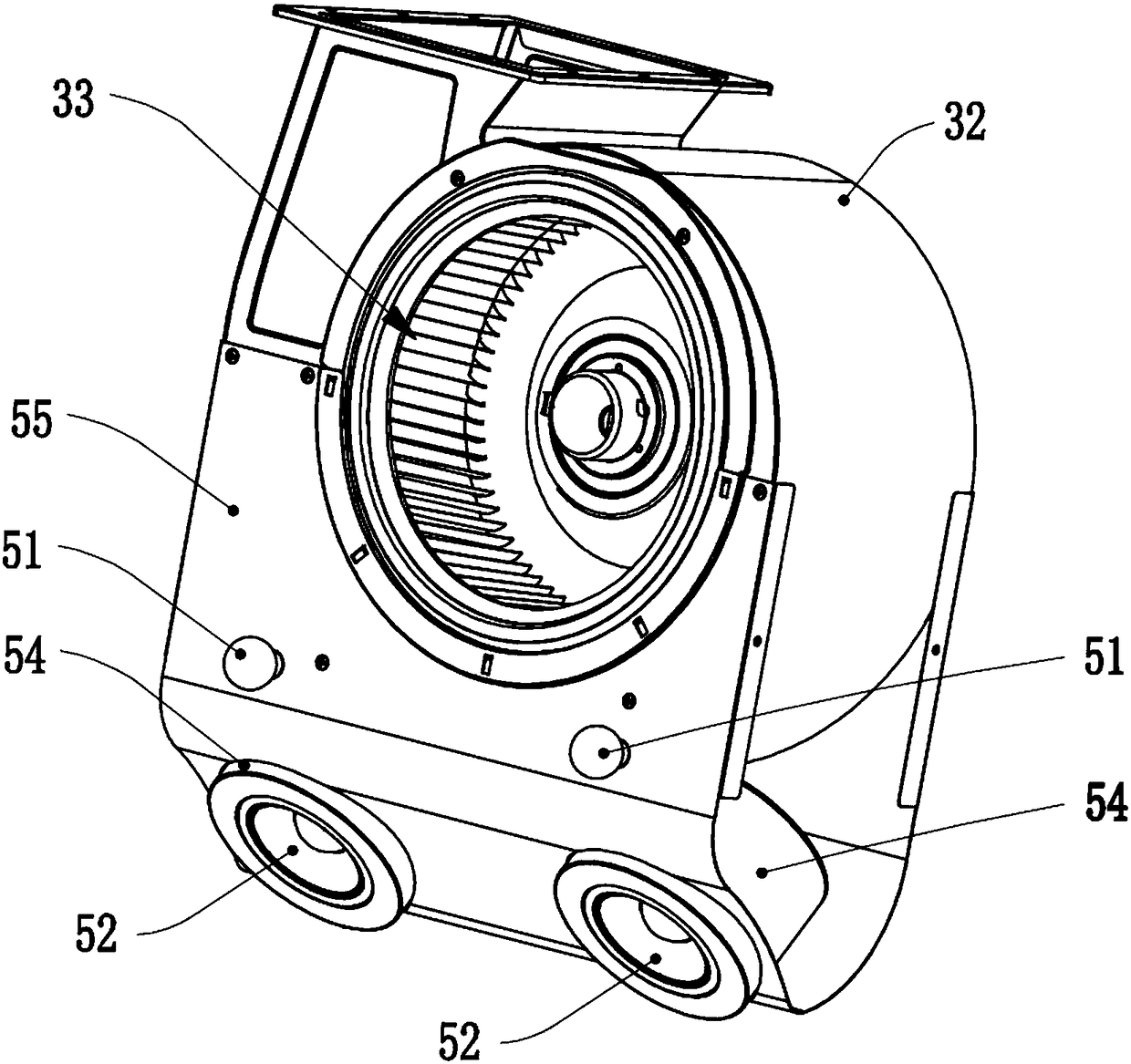

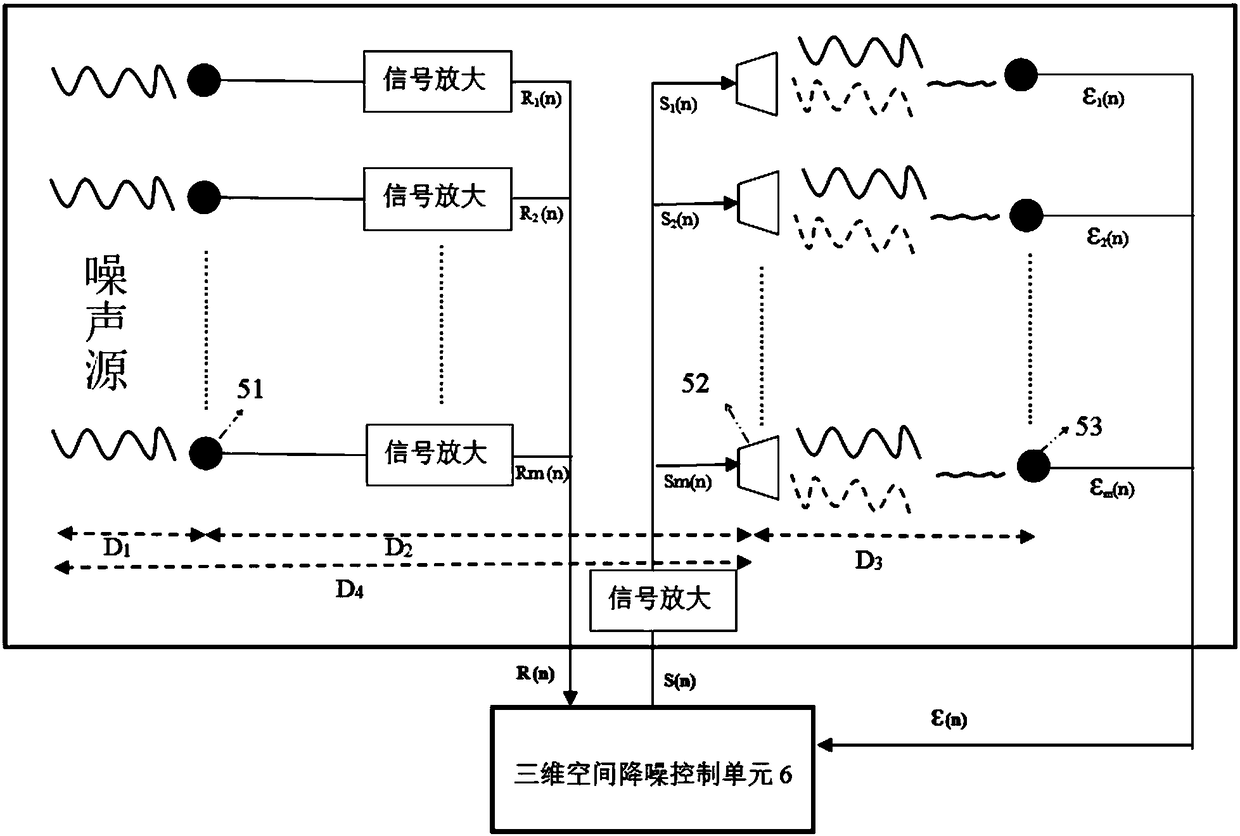

[0124] Such as Figure 1-Figure 4 As shown, an inclined hood with a three-dimensional sound field noise reduction device is installed above the cooker 01. The slanted hood includes a casing 1, a hood body 2, a fan assembly 3, a deflector assembly 4, Three-dimensional space sound field noise reduction device 5, adaptive three-dimensional space noise reduction control unit and visual inspection system 7;

[0125] The shell 1 is arranged outside the main body 2 of the hood as a device cover; the main body 2 of the hood is provided with an air inlet 21 and an air duct 22, and the air duct 22 is a low damping closed air duct; the low damping The pipe wall 20 of the closed air duct is provided with reinforcing ribs 201 and convex hulls 202, and the reinforcing ribs 201 and the convex hulls 202 are integrally formed with the duct wall 20;

[0126] The visual detection system 7 is installed on the deflector assembly 4, and the lens of its image acquisition device faces the cooker;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com