Optoacoustic spectroscopy multi-ingredient trace gas detection instrument and method

A trace gas, photoacoustic spectroscopy technology, applied in color/spectral property measurement, instruments, scientific instruments, etc., can solve the problems of difficult simultaneous coupling of mid-infrared thermal radiation light and laser light, low sensitivity of individual gas detection, etc., to meet the reduction requirements , the effect of simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention are described in detail below with reference to the technical solutions and the accompanying drawings.

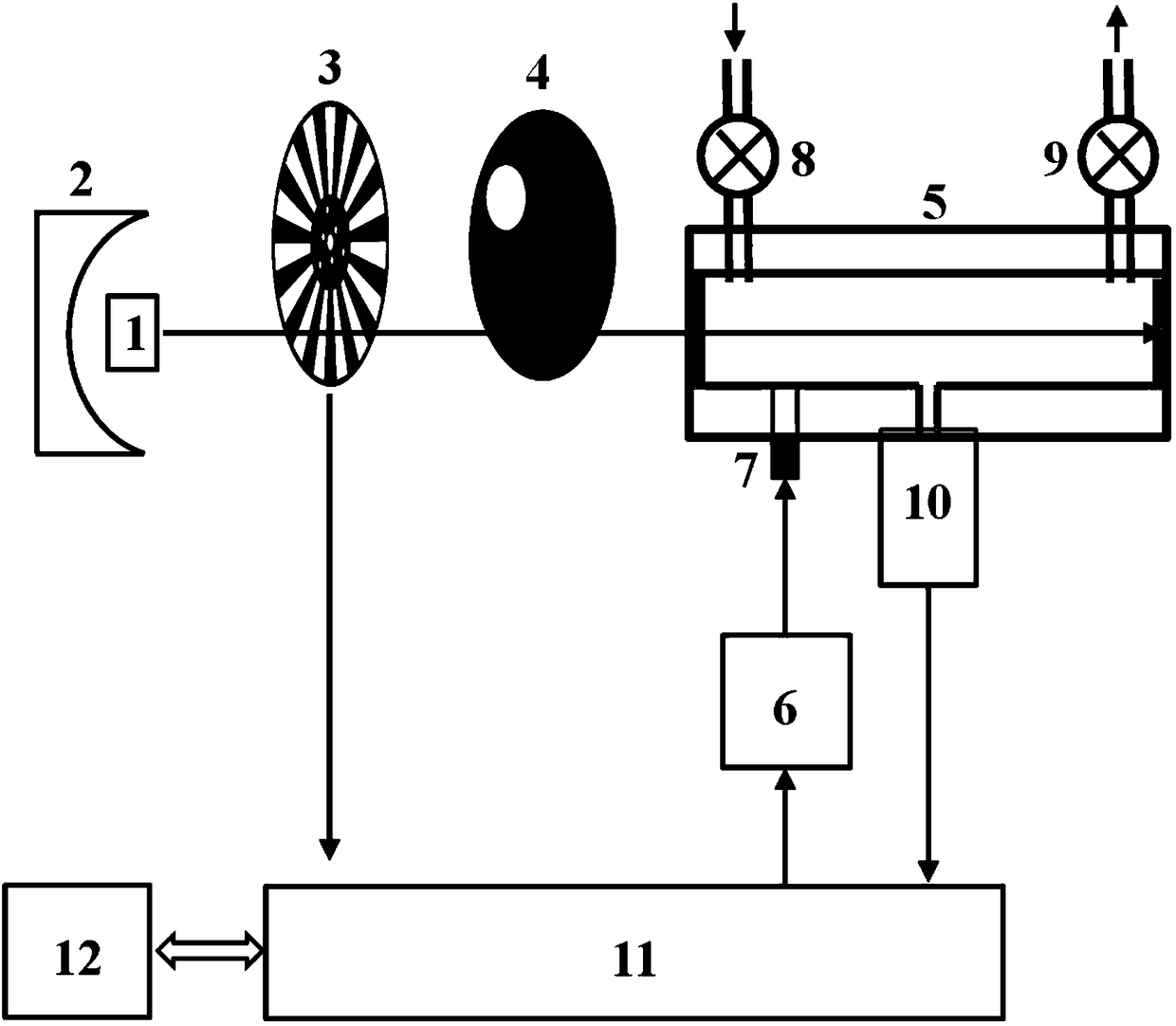

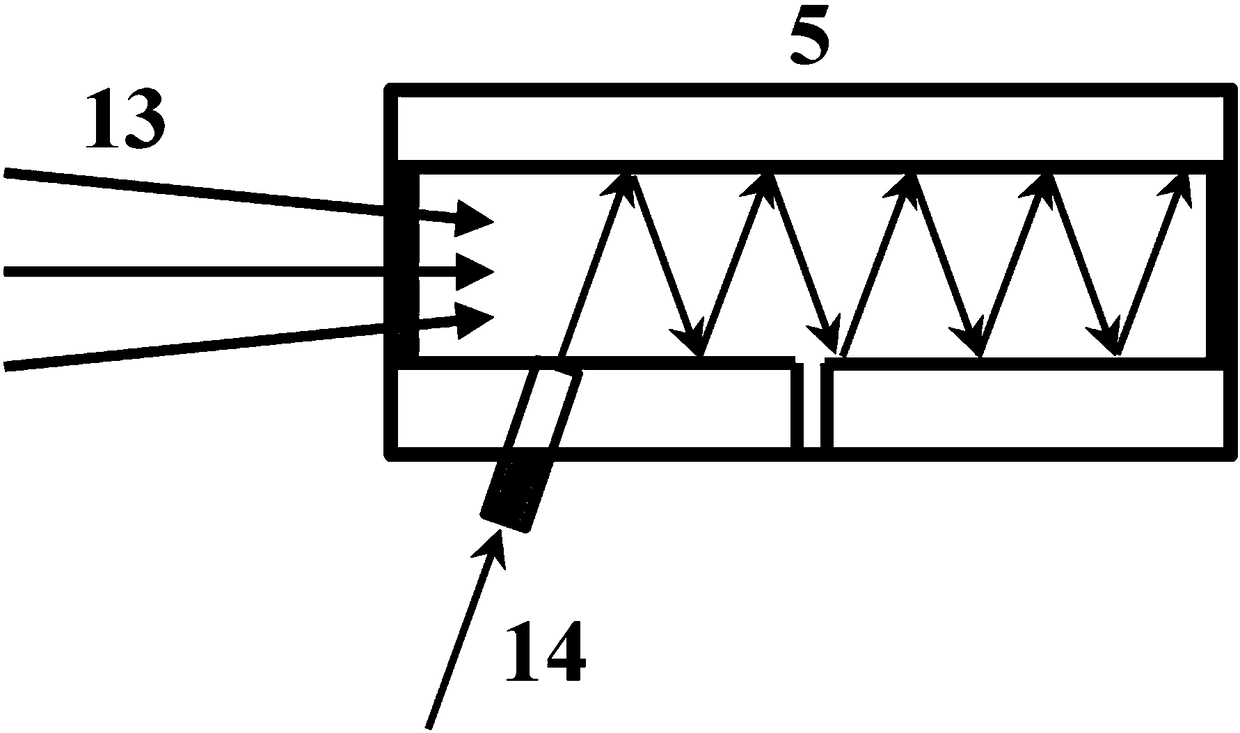

[0032]A photoacoustic spectrum multi-component trace gas detection instrument mainly includes a mid-infrared thermal radiation light source 1, a condenser 2, a chopper 3, a filter group 4, a photoacoustic cell 5, a laser light source 6, and an optical collimator 7 , intake valve 8 , outlet valve 9 , microphone 10 , control and signal processing circuit 11 and touch screen 12 . After the control and signal processing circuit 11 receives the control command input by the touch screen 12, it opens the air inlet valve 8 and the air outlet valve 9, so that the gas to be measured is filled with the photoacoustic cell 5, and the working parameters are set; After the light is focused by the condenser 2, it is modulated by the chopper 3; after the modulated light passes through a filter in the filter group 4, it is longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com