Manufacture method of high-strength disc porcelain insulator

A technology of porcelain insulators and insulators, which is applied in the field of manufacturing high-strength disc-shaped porcelain insulators, can solve problems such as glaze cracking, low strength of the insulator body, and structural strength limitations, so as to improve axial tensile and bending strength, improve Anti-fouling and anti-flash ability, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

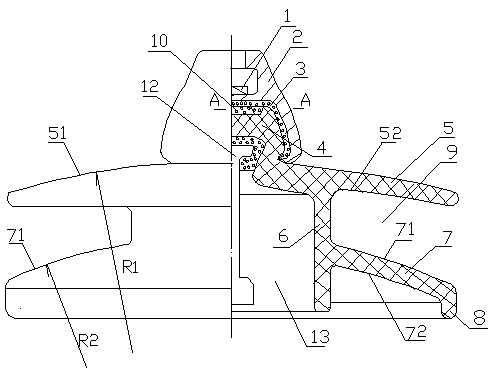

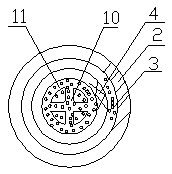

[0032] Example 1, in figure 1 and figure 2Among them, a high-strength disc-shaped porcelain insulator (specification model XP-70T), with a height of 146 mm and a maximum disc diameter of 255 mm), it includes an insulator body, a pressure plate 1, a steel cap 2 and a steel foot 12, the steel cap The high-strength disc-shaped porcelain insulator body includes a core head 4, a core bone 6, an upper shed 5 and a lower shed 7, and the upper shed and the lower shed The sheds have an upper shed outer surface 51 and a lower shed shed outer surface 71 respectively, and the upper shed shed outer surface 51 and the lower shed shed outer surface 71 are radii of curvature R1 (135-140mm) and R2 (120-130mm) respectively. Convex spherical surface, wherein R1 is greater than R2, the end face of the core head is provided with an annular groove 11 and a cross groove 10, a glue layer 3 is arranged between the end face of the core head and the steel cap, the cross section of the ring groove 11 a...

Embodiment 2

[0049] exist figure 1 and figure 2 Among them, a high-strength disc-shaped porcelain insulator (specification model XP-40C), with a height of 140 mm and a maximum disc diameter of 220 mm), it includes an insulator body, a pressure plate 1, a steel cap 2 and a steel foot 12, and the steel cap and the steel feet are glued and connected to the two ends of the insulator body with an adhesive layer. The high-strength disc-shaped porcelain insulator body includes a core head 4, a core bone 6, an upper shed 5 and a lower shed 7. The upper shed and the lower shed shed respectively have an upper shed shed outer surface 51 and a lower shed shed outer surface 71, and the upper shed shed outer surface 51 and the lower shed shed outer surface 71 are respectively R1 (125-130mm) and R2 (110- 120mm) convex spherical surface, wherein R1 is greater than R2, an annular groove 11 and a cross groove 10 are arranged on the end surface of the core head, a glue layer 3 is formed between the end su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com