Transmission mechanism for 40.5kV switch cabinet isolation switch

A technology of isolating switch and transmission mechanism, which is applied in the direction of electric switch, air switch parts, high-voltage air circuit breaker, etc., which can solve the problems of unfavorable switch cabinet normal use, AC skin effect, conductive circuit overheating, etc., and facilitates industrial production , Occupy small space, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

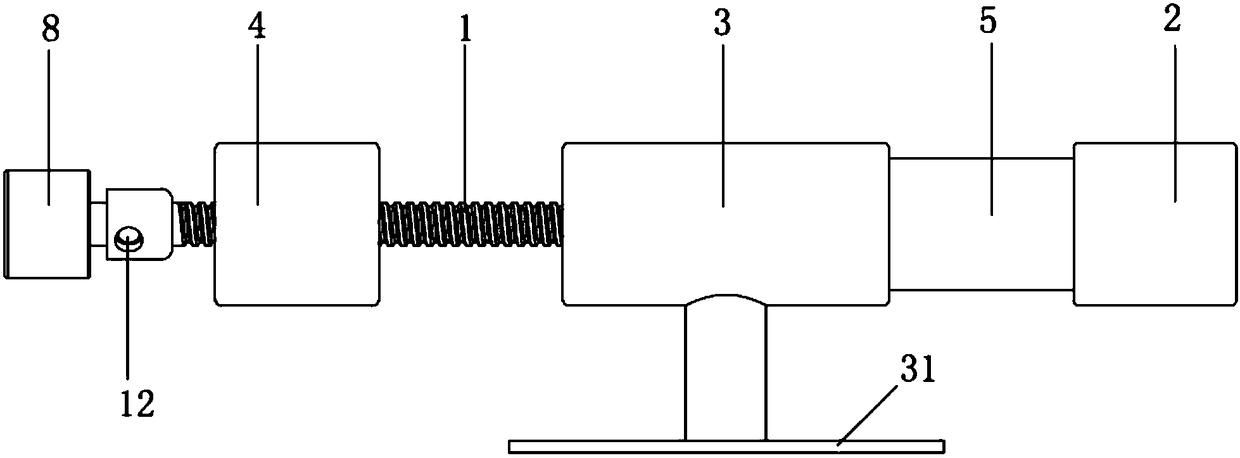

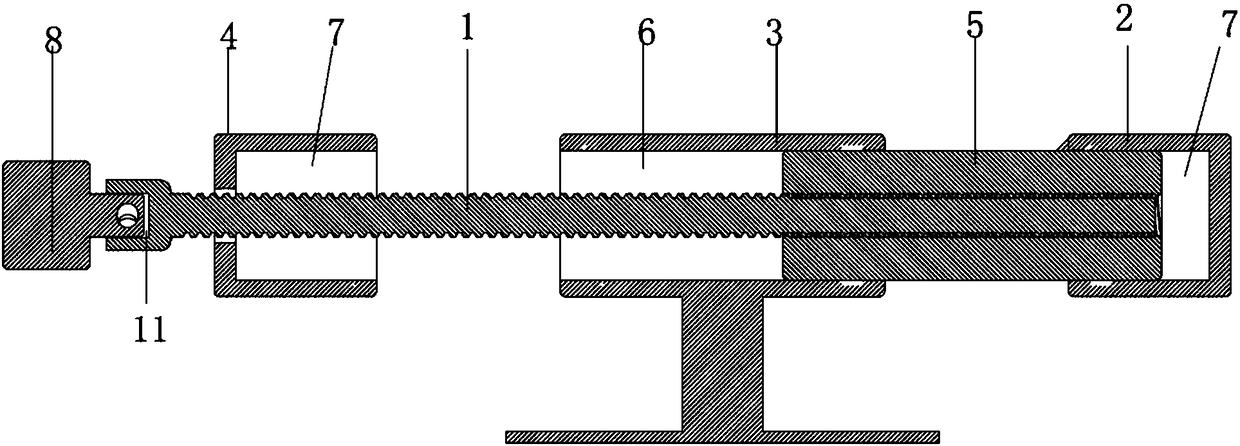

[0024] Such as Figure 1 to Figure 2 As shown, a transmission mechanism for a 40.5kV switchgear isolating switch shown in this embodiment includes an insulating screw 1, and a grounding contact 4 is sequentially sleeved on the screw thread at the position from the head to the tail of the insulating screw 1 , insulated moving contact bracket 3 and static contact 2, and the grounding contact 4, moving contact bracket 3 and static contact 2 are all fixed on the switchgear (not shown in the figure) and do not contact the insulating screw 1 , a through hole 6 is provided on the moving contact bracket 3, the insulating screw 1 passes through the through hole 6, and the moving contact 5 is arranged in the through hole 6, and the moving contact 5 and the insulating screw 1 are connected by threads One end of the ground contact 4 and the static contact 2 close to the movable contact bracket 3 is provided with a slot 7 for accommodating the movable contact 5, and the movable contact 5 c...

Embodiment 2

[0027] Such as figure 1 and figure 2 As shown, a transmission mechanism for a 40.5kV switch cabinet isolating switch shown in this embodiment, on the basis of the structure described in Embodiment 1, is connected to the head of the insulating screw 1 for driving the rotation of the insulating screw 1 The motor 8 is fixed on the switch cabinet.

[0028] Specifically, the outer end surface of the head of the insulating screw 1 is provided with a fixing hole 11 for accommodating the rotating shaft of the motor 8, and the insulating screw 1 and the rotating shaft of the motor 8 within the range of the fixing hole 11 are provided with corresponding pin holes 12, through which the pins Through the pin hole 12, the rotating shaft of the motor 8 is fixed in the fixed hole 11, and the moving contact moves back and forth on the insulating screw through the forward rotation and reverse rotation of the motor, and the automatic control and closing of the grounding contact or the static c...

Embodiment 3

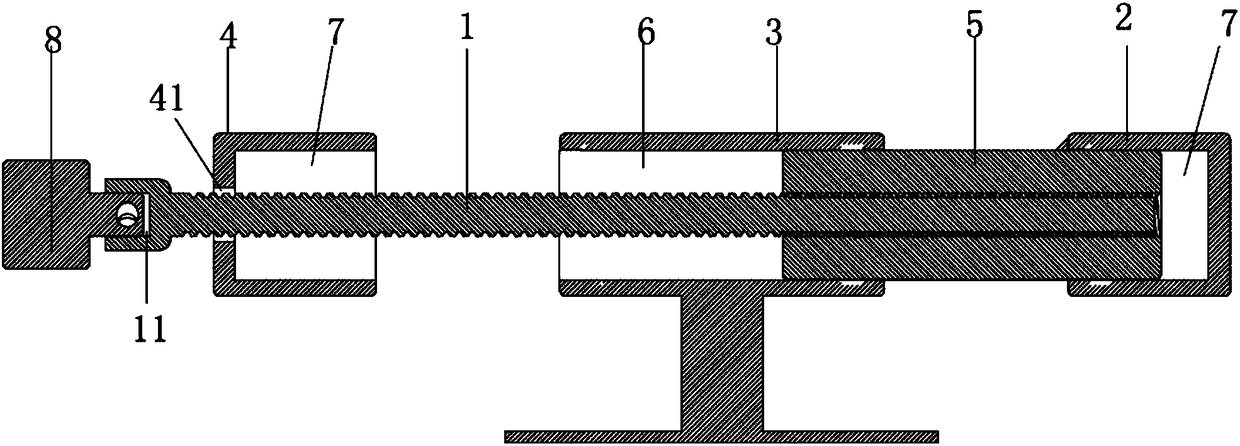

[0030] Such as figure 1 and image 3 As shown in this embodiment, a transmission mechanism for a 40.5kV switchgear isolating switch, on the basis of the structure described in Embodiment 2, the end of the static contact 2 away from the moving contact bracket 3 is closed , so that the tail of the insulating screw 1 is placed in the slot 7 in the static contact 2 to ensure that the movable contact can move into the slot 7 in the static contact 2; There is a shaft hole 41 for the insulating screw 1 to pass through, and the diameter of the shaft hole 41 is larger than that of the insulating screw 1 .

[0031] Specifically, the through hole 6 and the slot 7 are square holes with the same size, and the moving contact 5 is a square shape with the same size as the square hole; the length of the moving contact 5 is longer than that of the moving contact bracket 3 and the side of the slot 7 The distance between the walls is such that after the moving contact 5 enters the slot 7, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com