Inkjet printing technology based flexible wearable system and manufacturing method thereof

A technology of inkjet printing and printing manufacturing, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of overcoming pollution and material loss, green pollution-free manufacturing, energy-saving and emission-reducing manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

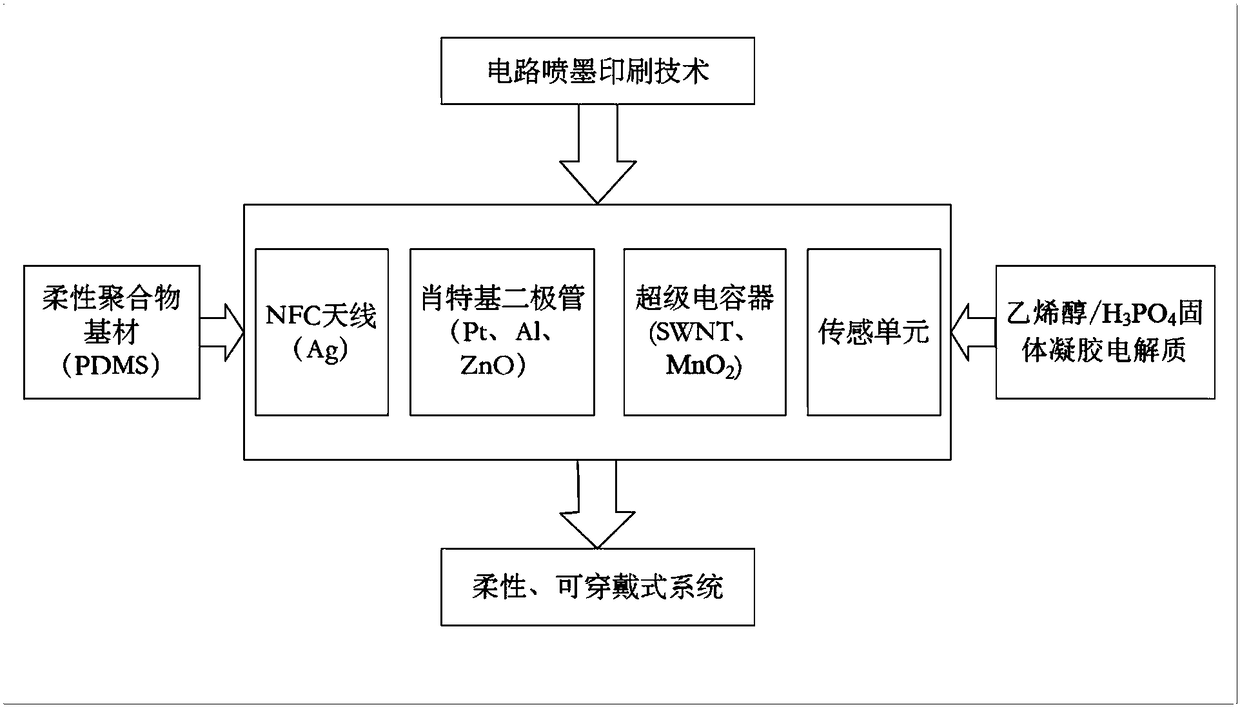

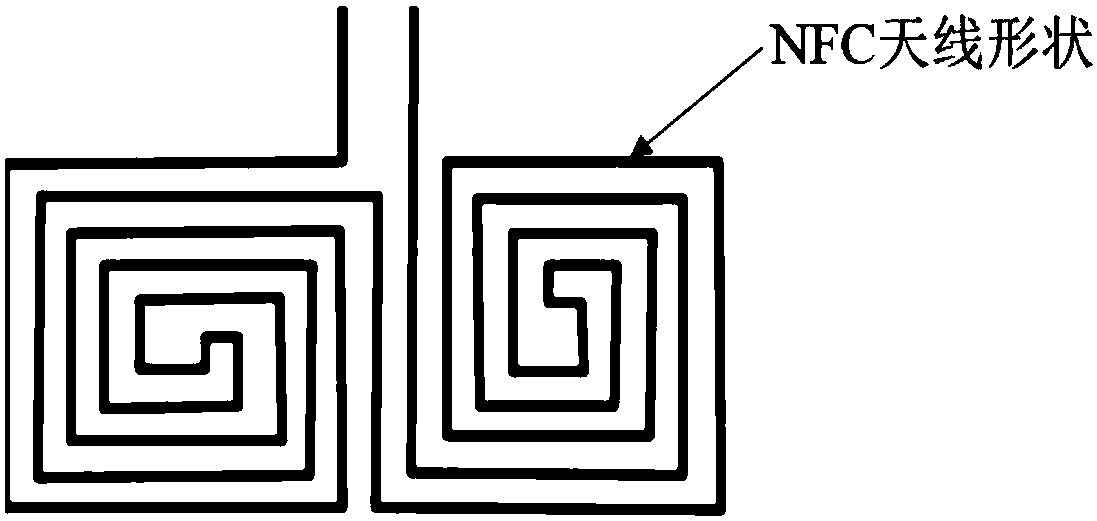

[0031] A flexible wearable system based on inkjet printing technology is shown in the figure. The system uses inkjet printing technology to print circuits, including printing integrated NFC antennas, Schottky diodes, A supercapacitor and a sensor, and an encapsulation layer is arranged outside the system;

[0032] The NFC antenna is used to receive wireless energy;

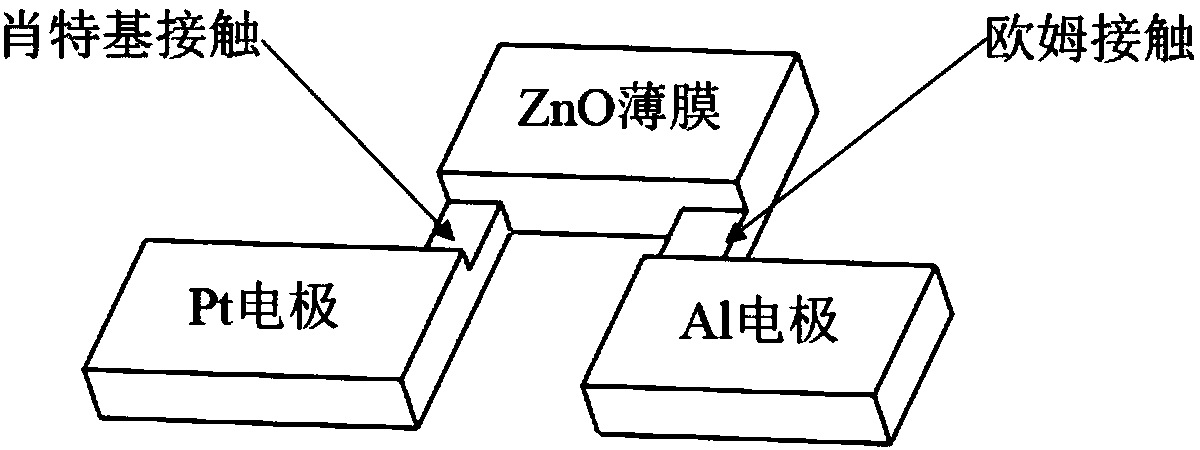

[0033] The Schottky diode is used for full-wave rectification of energy;

[0034] The supercapacitor is used to store energy;

[0035] The sensor is selected according to the purpose of use.

[0036] Wherein, the NFC antenna is manufactured by printing silver (Ag) nanoparticles on the zinc oxide film; the Schottky diode is manufactured by printing on the zinc oxide film by using platinum (Pt) nanoparticle ink and aluminum (Al) nanoparticle ink; Supercapacitors are fabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com