PCB inner line graph transfer process

A technology of graphic transfer and inner layer circuit, which is applied in the direction of circuit cover, printed circuit, printed circuit manufacturing, etc., can solve the problems of wasting electricity and time, high cost, and environmental protection, so as to improve the process ability, improve the manufacturing ability, work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, and the present invention is not limited to the following specific embodiments.

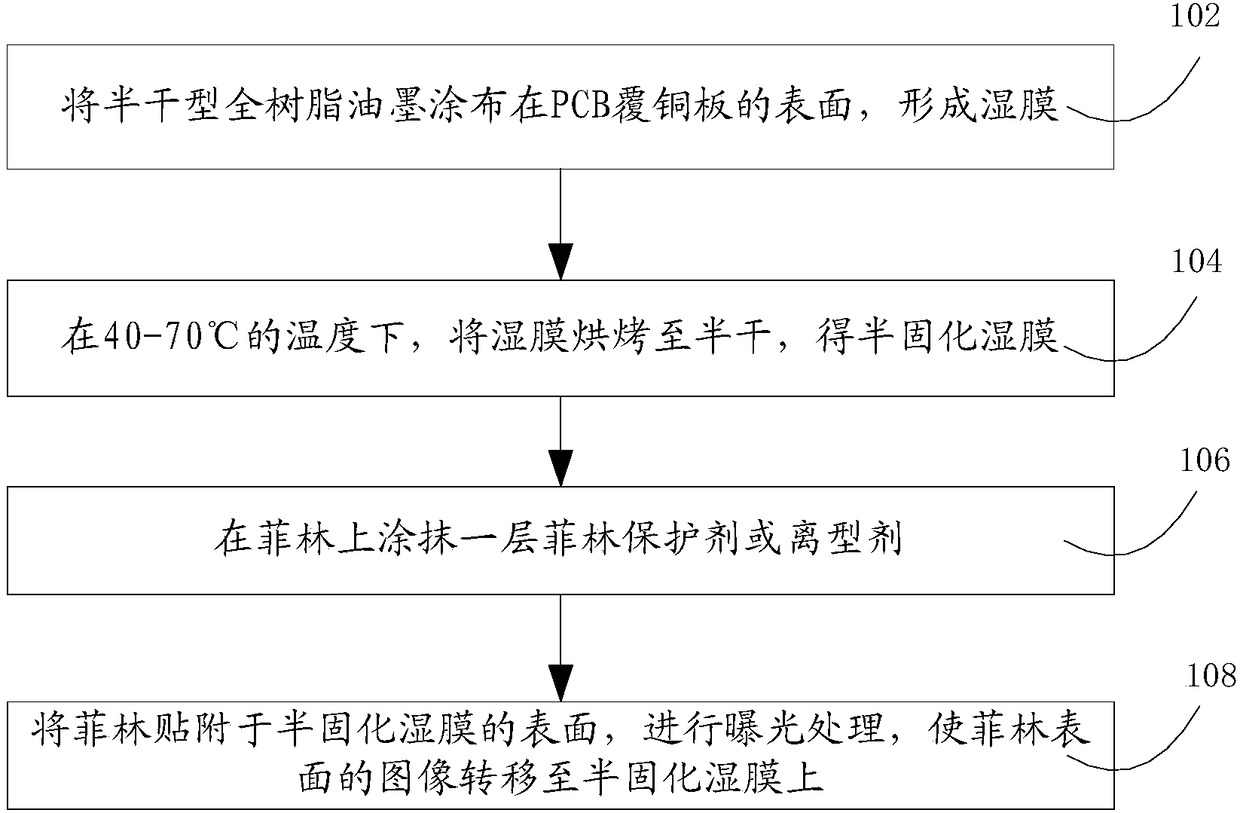

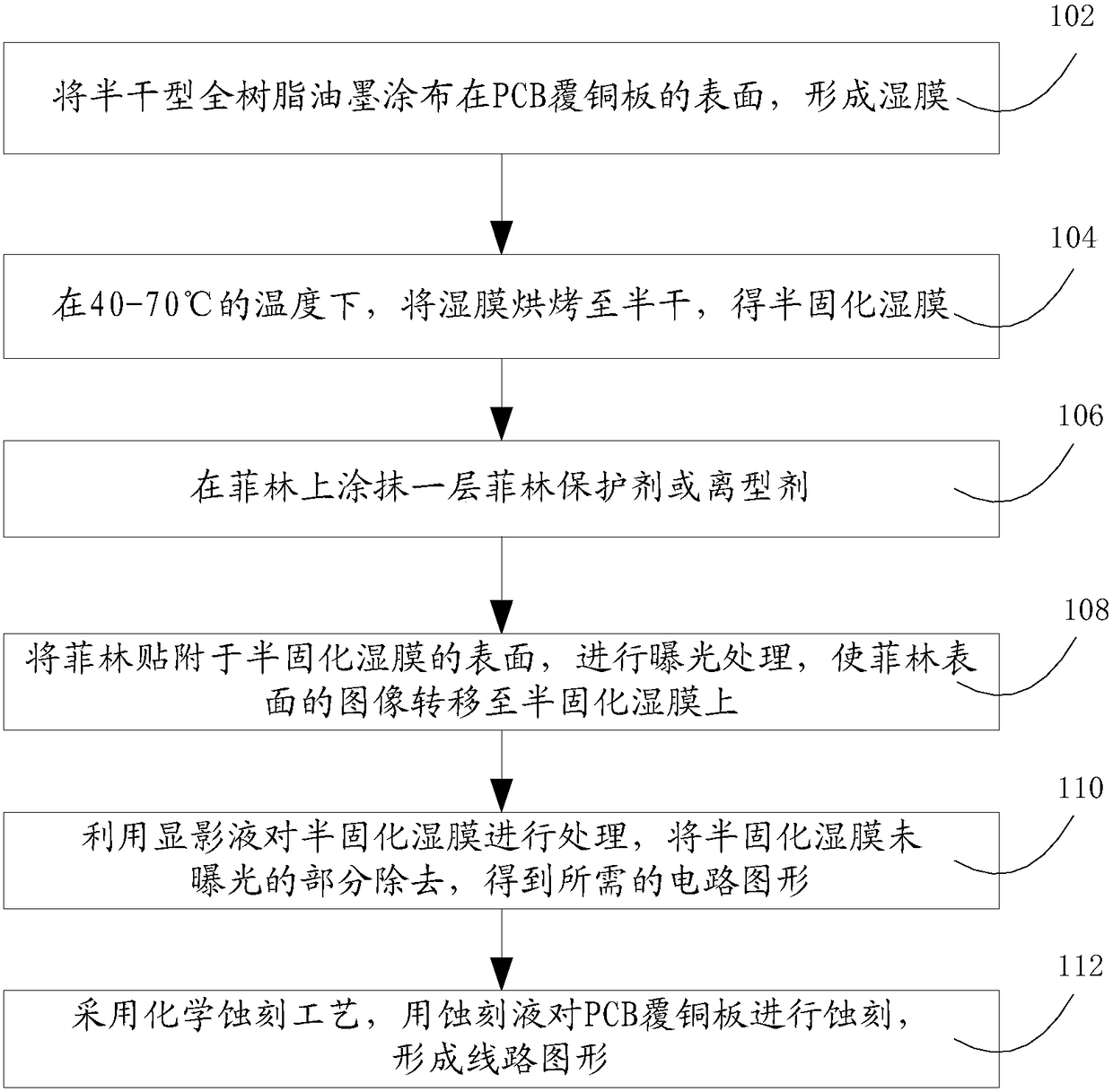

[0023] The invention provides a PCB inner layer circuit graphics transfer process, such as figure 1 shown, including the following steps.

[0024] Step 102, coating the semi-dry full resin ink on the surface of the PCB copper clad board to form a wet film. This step may also be referred to as an ink coating step.

[0025] Step 104, at a temperature of 40-70° C., bake the wet film until it is semi-dry to obtain a semi-cured wet film. This step can also be called a pre-baking step.

[0026] Step 106, apply a layer of film protection agent or release agent on the film. This step can also be referred to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com