Automobile part processing device

A technology for processing devices and auto parts, which is applied in the field of parts processing devices and can solve problems such as sewer wastewater cannot circulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

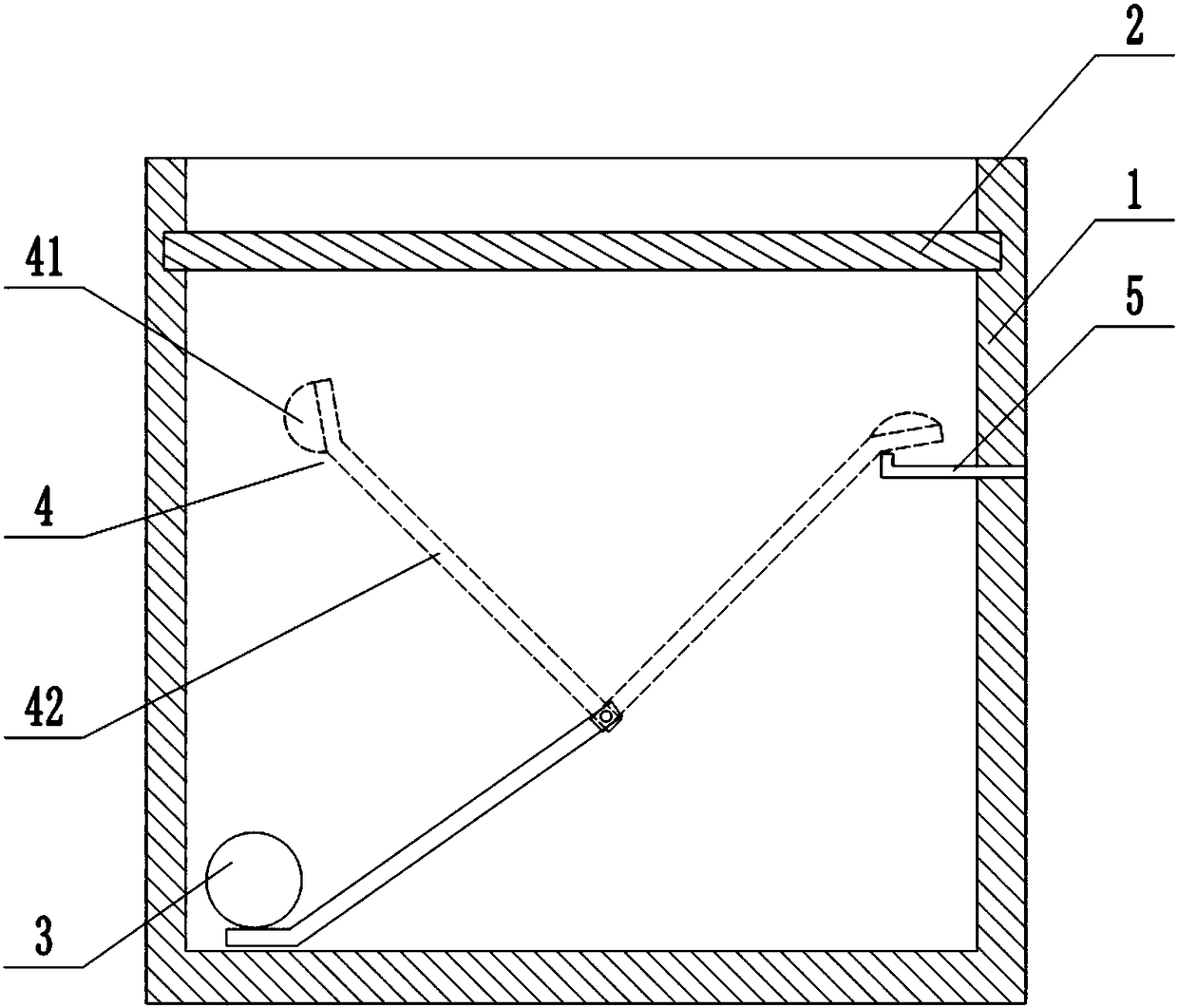

[0031] Such as figure 1 , figure 2 As shown, the auto parts processing device includes a filter tank 1, a cleaning part 4 and a recovery part 5. The filter tank 1 is horizontally slidably connected with a movable plate 2, and the movable plate 2 is opened with water leakage holes. The movable plate 2 divides the filter tank 1 into There are two parts, the upper pool and the lower pool. The upper pool is used for cleaning parts, and the lower pool collects the cleaned sewage. There is also a water outlet 3 on the side wall in the lower left direction of the filter pool 1. The water outlet 3 is connected with the downpipe. The water port 3 is fixedly connected with a filter screen.

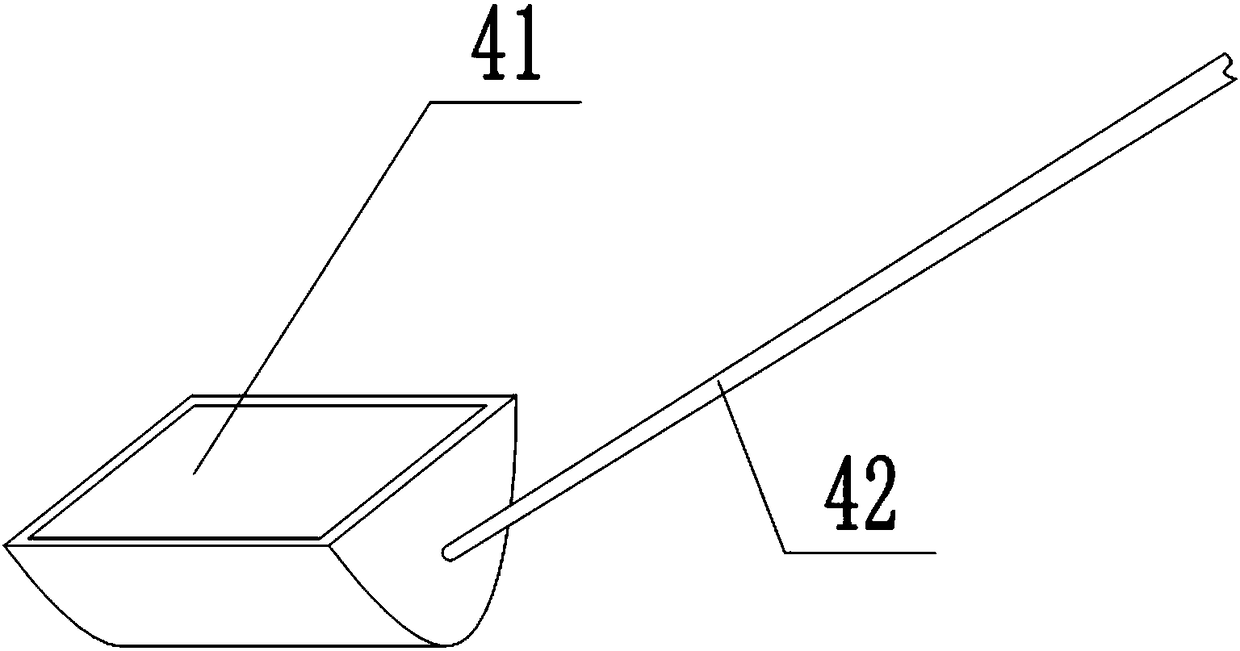

[0032] The cleaning part 4 includes a filter screen 41 and a rotating shaft 42, such as figure 1 , image 3 As shown, the left end of the rotating shaft 42 is fixedly connected with the filter screen 41, and the rotating shaft 42 is vertically fixedly connected with an articulated shaft 7, and t...

Embodiment 2

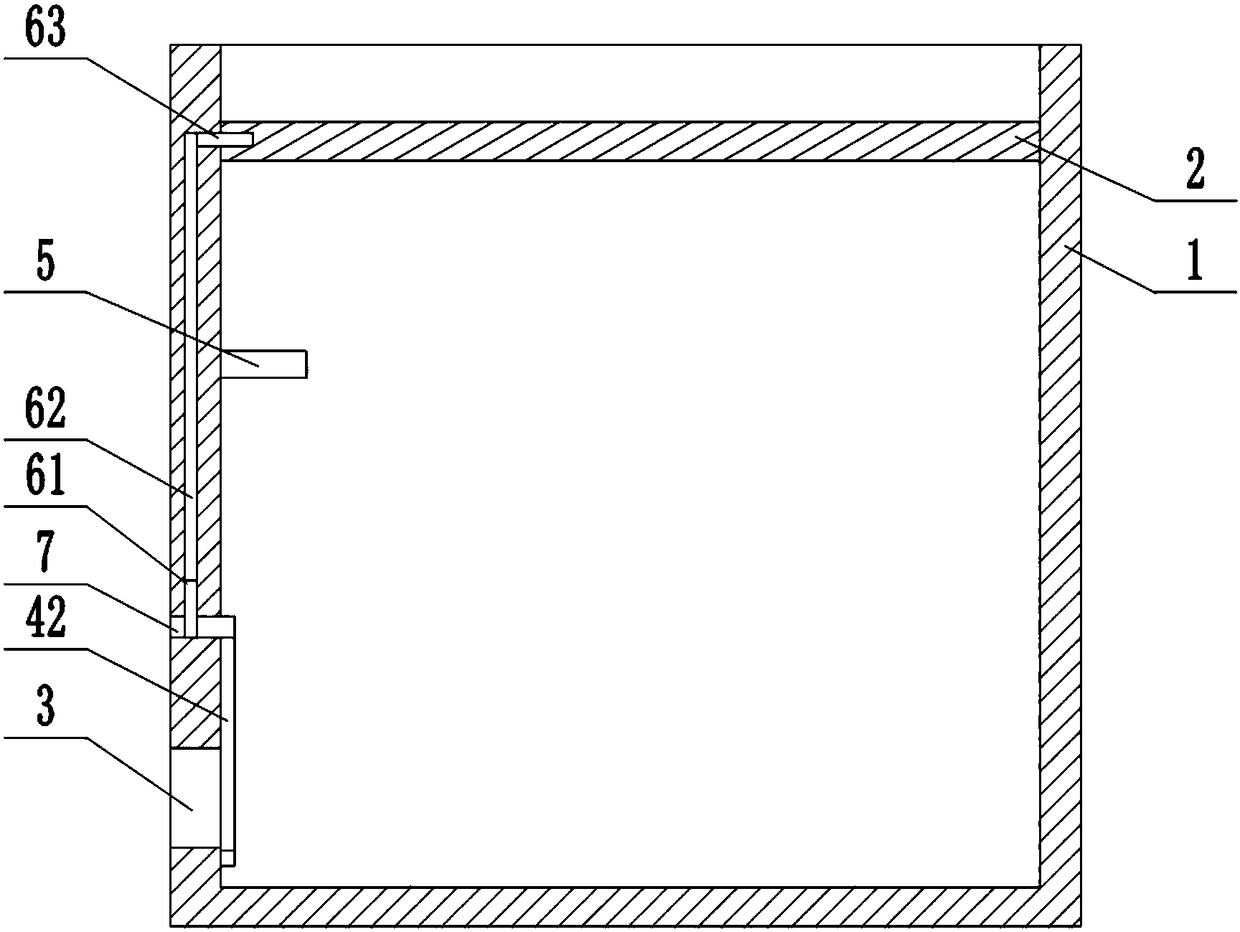

[0040] Such as Figure 5 As shown, the difference between the automobile parts processing device and the first embodiment is that the rotating shaft 42 and the filter screen 41 of the cleaning part 4 are hingedly connected, and a filter screen 41 is also provided between the rotating shaft 42 and the filter screen 41. position of the torsion spring, so the filter screen 41 will rotate relative to the rotating shaft 42 under force, but when the external force is lost, the filtering screen 41 will return to its original position and form a fixed angle of 150° with the rotating shaft 42. Such as Figure 6 As shown, an opening is provided on the pool wall, and the recovery part 5 passes through the opening and is fixed on the right side wall of the filter pool 1 inclined outward. Wherein, the power source driving the rotation of the cleaning part 4 is an electric motor.

[0041]During specific implementation, the cleaning part 4 will rotate clockwise under the traction of the mo...

Embodiment 3

[0044] Such as Figure 7 As shown, the difference between the auto parts processing device and the first embodiment is that the filter screen 41 of the cleaning part 4 is provided with a driving lever 43, and the middle part of the driving lever 43 is hinged with the end of the rotating shaft 42 near the filter screen 41, and the driving lever One end of 43 stretches in the filter screen 41. Wherein, the power source driving the rotation of the cleaning part 4 is a forward and reverse motor. When the cleaning part 4 turns to the position of the recovery part 5, the recovery part 5 will squeeze the lower end of the driving rod 43, causing the upper end of the driving rod 43 to rotate downward, thereby removing the impurities in the filter screen 41 from the filter screen 41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com