A jacking mechanism for a stamping die

A technology of ejecting mechanism and stamping die, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the ejecting mechanism does not have dust removal function, is inconvenient for buffer strength, and is inconvenient for heat dissipation of workpieces, and achieves increased stability. , Safe and convenient to use, press down and push out stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

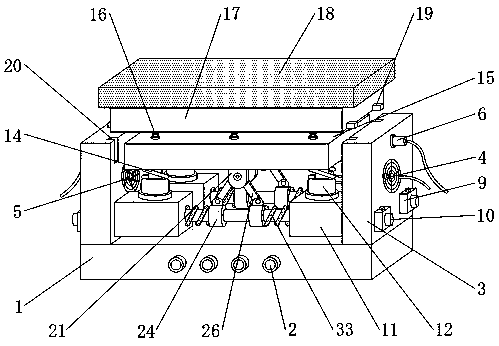

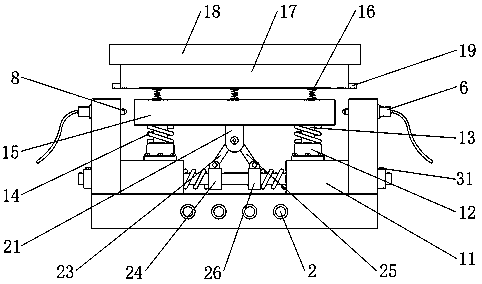

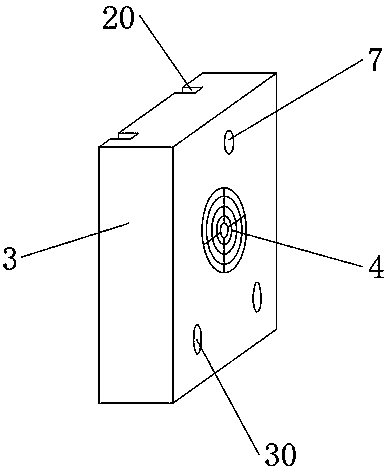

[0029] see Figure 1-7 , in an embodiment of the present invention, a material ejecting mechanism for a stamping die includes a fixed seat 1, a control button 2 is provided on the front surface of the fixed seat 1, and two side plates are connected to the top edge of the fixed seat 1 in a symmetrical structure 3. A tuyere 4 is set in the middle of the side plate 3, a fan 5 is installed inside the tuyere 4, a hydraulic telescopic rod 6 is installed on the outer wall of the side plate 3 above the tuyere 4, and the output end of the hydraulic telescopic rod 6 is located on the side plate 3 The inner side of the side plate 3 is connected with a block 8, and the inside of the side plate 3 is provided with a first fixing hole 7 corresponding to the output end of the hydraulic telescopic rod 6. Block 9, the middle part of the fixed block 9 is located above the fixed seat 1 and is inserted with a fixed rod 10, and the inside of the fixed block 9 is provided with a fourth fixed hole 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com