Full-automatic tooth welding machine

A gear welding machine and fully automatic technology, which is applied in the field of gear welding machines, can solve the problems of low work efficiency and high labor intensity, and achieve the effects of simple structure, reduced labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

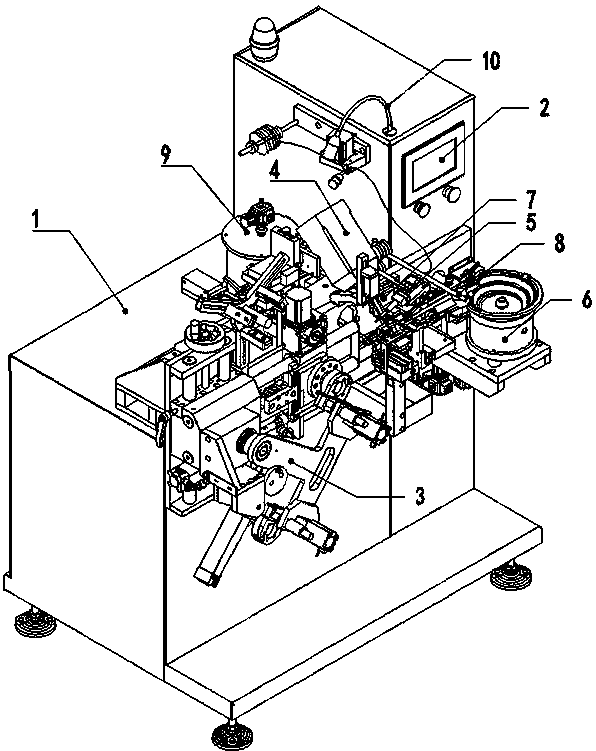

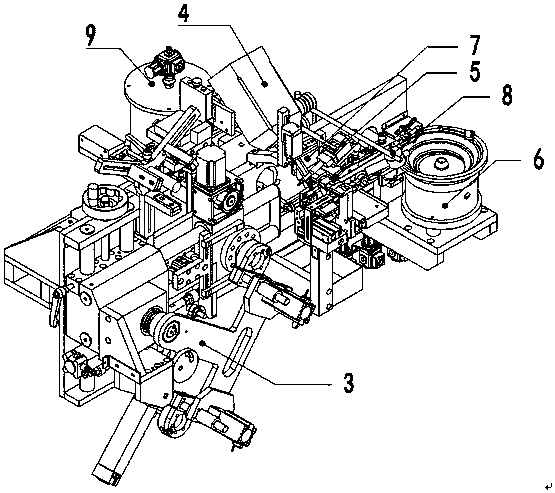

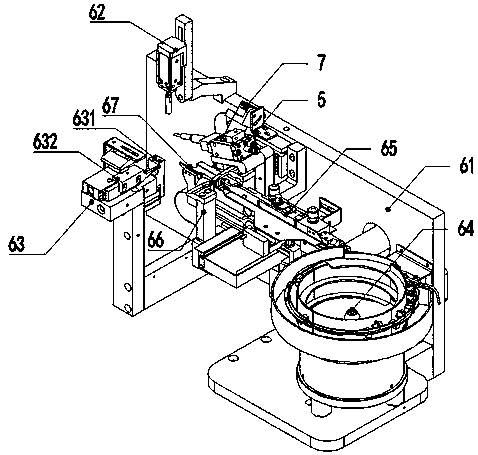

[0024] Depend on figure 1 , figure 2 , image 3 Known, a kind of full-automatic gear welding machine, comprises chassis 1, and described chassis 1 is provided with touch screen 2, and is provided with electrical control system in chassis 1; Described chassis 1 is also provided with mechanical arm mechanism 3, Welding mechanism 4, welding wire feeding mechanism 5, alloy cutter head conveying mechanism 6 and glue dispensing mechanism 7; Between; described mechanical arm mechanism 3 is provided with laterally moving saw blade suction cup assembly 31, loading and unloading blade mechanical arm assembly 32, loading rack assembly 33 and unloading rack 34; described alloy cutter head conveying mechanism 6 is fixed on The installation frame 61 on the cabinet 1, the longitudinal sheet pressing mechanism 62, the saw blade welding tooth position correction mechanism 63, the material selection tray mechanism 64, the conveying mechanism 65, the conveying clamp mechanism 66 and the saw b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com