Composite coating with photo-thermal conversion capability changing with environmental temperature variation and preparation method thereof

A composite coating and ambient temperature technology, applied in coatings, unspecified rubber coatings, reflective/signal coatings, etc., can solve problems such as increased proportion, low emissivity, and reduced wall emissivity, achieving savings The cost of air conditioning, the convenience of the preparation method, and the effect of increasing the emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

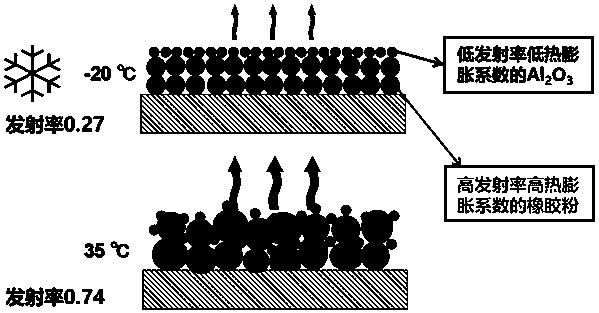

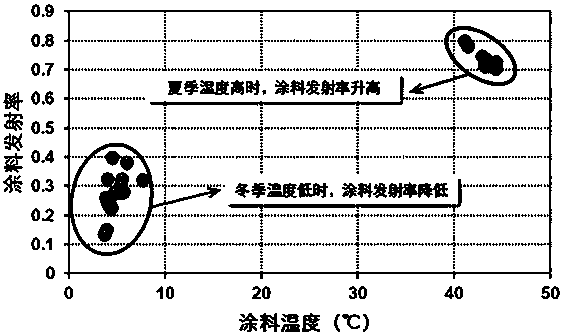

[0019] Specific Embodiment 1: This embodiment describes a composite coating whose light-to-heat conversion ability can change with the ambient temperature, and the composite coating is composed of a bottom coating and a surface coating;

[0020] The raw material of the primer coating contains high emissivity / high thermal expansion rate powder, and the raw material of the surface layer coating contains low emissivity / low thermal expansion rate powder.

specific Embodiment approach 2

[0021] Embodiment 2: A composite coating whose light-to-heat conversion ability can change with the ambient temperature described in Embodiment 1, the high emissivity / high thermal expansion rate powder is hard rubber powder, cuprous oxide or The lead boron glass has a particle size of 100-5000 μm; the low emissivity / low thermal expansion powder is aluminum oxide, tungsten wire, iron powder, tin or zinc, and the particle size is 0.15-70 μm.

[0022] Specific embodiment three: a composite coating whose light-to-heat conversion ability can change with the ambient temperature described in specific embodiment two, the particle size of the low emissivity / low thermal expansion rate powder is 40-60 μm, within this range The particle size effect is better.

specific Embodiment approach 4

[0023] Embodiment 4: A method for preparing a composite coating whose light-to-heat conversion ability can vary with ambient temperature as described in any of Embodiments 1 to 3. The specific steps of the method are as follows:

[0024] Step 1: Prepare two equal parts of paint colloid, which are divided into paint colloid A and paint colloid B; add high emissivity / high thermal expansion rate powder to paint colloid A, and then add water to make a primer. Colloid A: high emissivity / high thermal expansion rate powder: water mass ratio=50~80:10~20:15~25; add low emissivity / low thermal expansion rate powder to coating colloid B, then add water, Make the surface coating, among which, the mass ratio of coating colloid B: low emissivity / low thermal expansion powder: water = 50~80: 10~20: 15~25, use appropriate amount of film forming and defoaming according to the prepared coating , dispersing, thickening and other additives, that is, two coatings are prepared; when additives are add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com