Plate bending device

A bending device and sheet technology, applied in sheet metal processing and sheet bending fields, can solve problems such as scratches, damage to the appearance of sheet metal parts, grooves, etc., and achieve the effect of improving efficiency

Active Publication Date: 2018-09-21

宁波高新区新柯保汽车科技有限公司

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, the cutting knife will produce a lot of debris when cutting the plate, and some of the debris is attached to the surface of the plate. When the stamping block stamps the plate, the debris is located between the stamping block and the plate, or between the plate and the fixed table. During the interval, under the pressure of the stamping block, it is easy to form grooves or scratches on the surface of the sheet metal, which will damage the appearance of the sheet metal parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

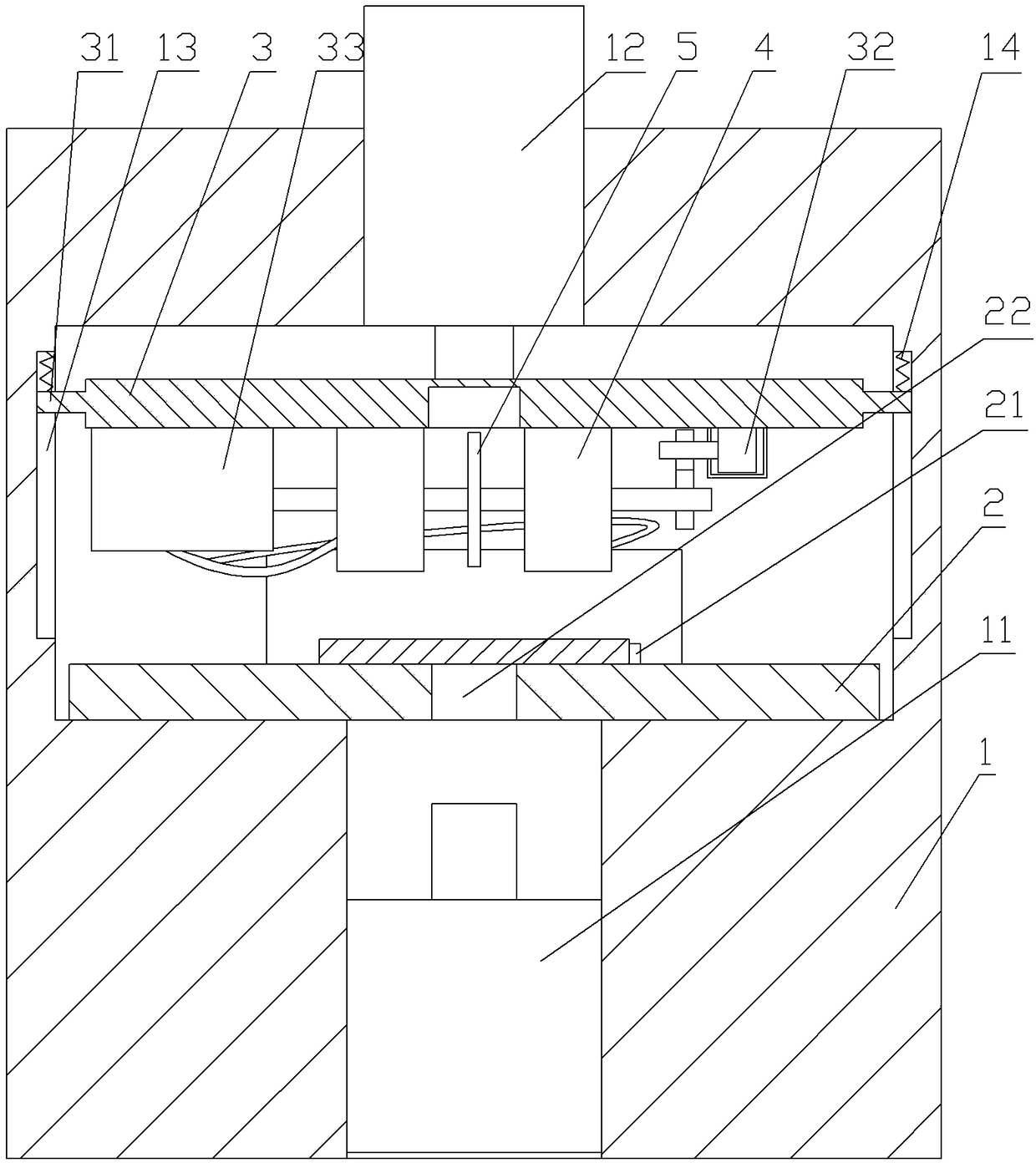

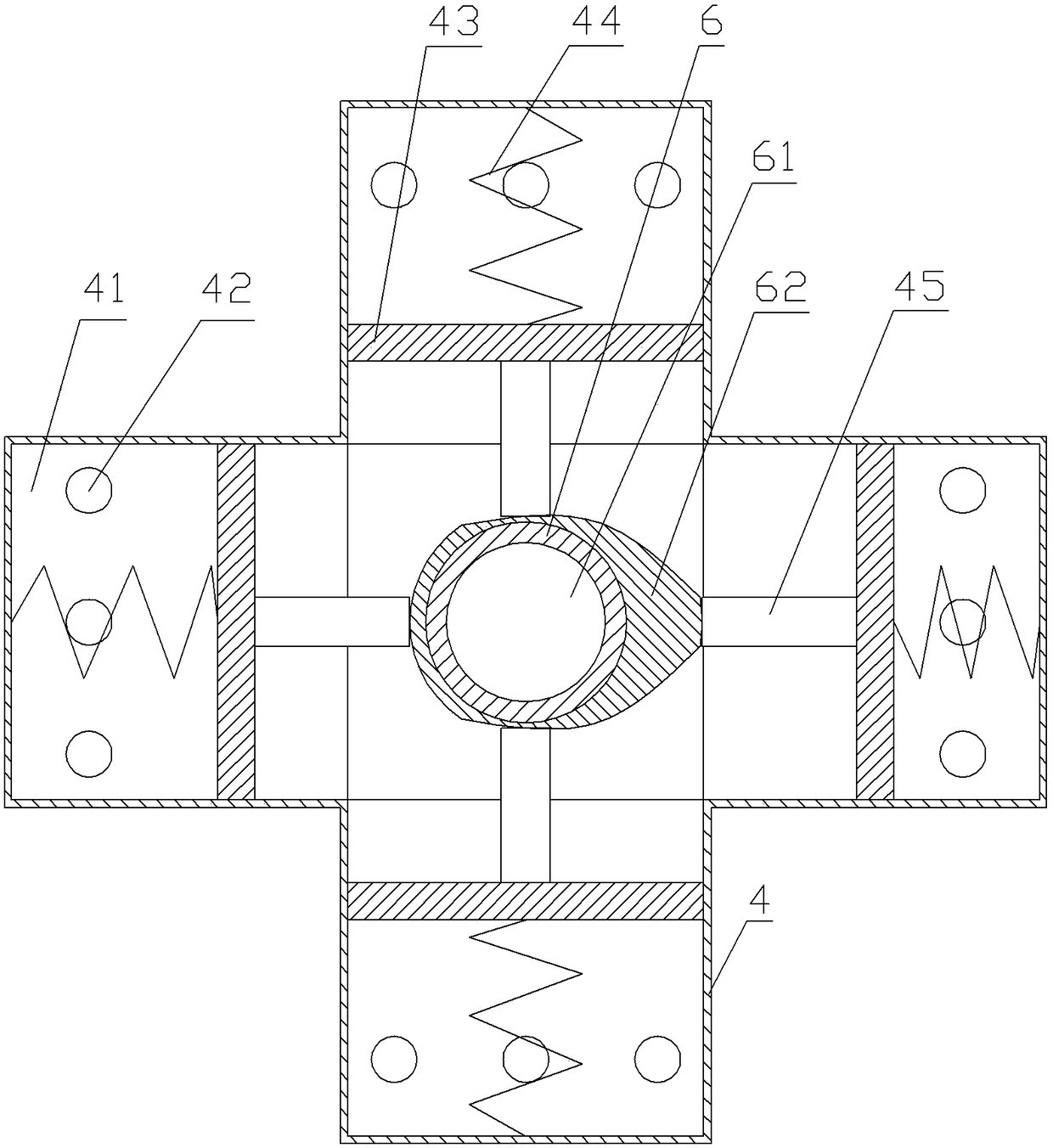

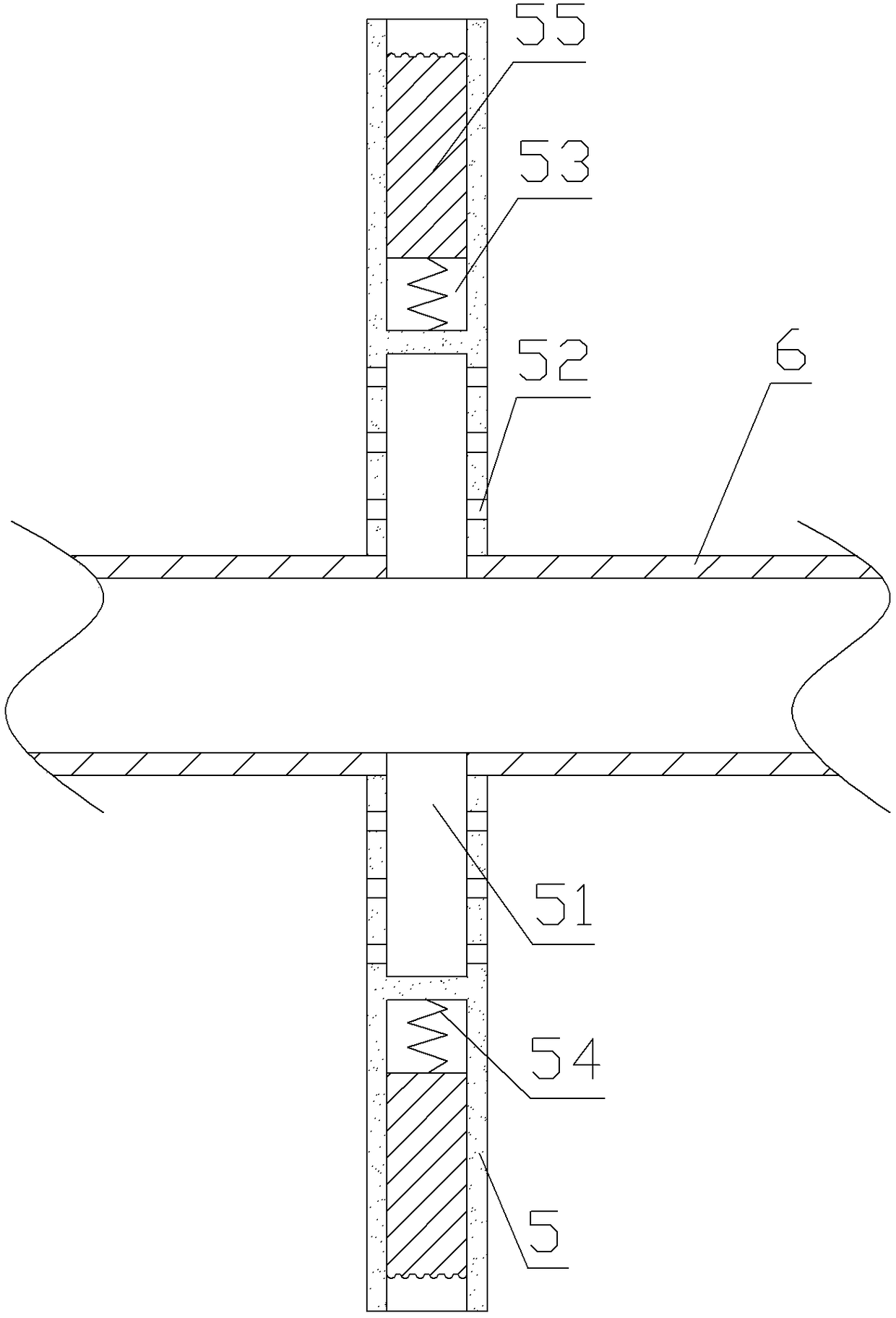

The invention relates to the field of plate processing and particularly discloses a plate bending device. The device comprises a frame, a pressing hydraulic cylinder, a cutting mechanism, a workbench,a punch and a punching hydraulic cylinder, wherein a punching channel is arranged in the workbench; a fixing seat is fixed on a push rod of the pressing hydraulic cylinder; the cutting mechanism comprises a rotating shaft, a rotating disk, a motor, a collecting box and pressing blocks; the rotating shaft penetrates through the pressing block; a discharge hole is formed in the collecting box; a filter screen is fixed in the collecting box; a cavity communicated with the collecting box is arranged in the rotating shaft; sliding cavities are arranged in the pressing block; pistons are arranged in the sliding cavities; piston rods are fixed on the pistons; cams are fixed on the rotating shaft; first springs are arranged in the sliding cavities; air inlet check valves and air outlet check valves are fixed on side walls of the sliding cavities; sliding-out grooves are arranged in the rotating disk; second springs and polishing pieces are arranged in the sliding-out grooves; and suction holes are formed in two sides of the rotating disk. According to the scheme, the device has the advantages that chips generated by cutting can be cleaned in time and scratches on plates are avoided.

Description

technical field [0001] The invention relates to the field of plate processing, in particular to the field of plate bending. Background technique [0002] Sheet metal is a comprehensive cold working process for metal sheets with a thickness below 6mm, including shearing, punching, cutting, compounding, folding, welding, riveting, splicing, forming, etc. The products processed by the metal industry are called sheet metal parts. Due to the characteristics of light weight, high strength, electrical conductivity, low cost, and good performance in mass production, sheet metal parts have been widely used in electronic appliances, communications, automobile industry, medical equipment and other fields. [0003] In the production process of sheet metal parts, the entire sheet needs to be cut first, and then the cut sheet is subjected to cold processing such as bending, stamping, welding, etc., and finally the sheet metal parts are formed. When the plate needs to be bent, the plate ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D5/04B21D43/28B08B5/02B08B15/04B24B7/10B24B55/06B24B27/00

Inventor 孙文清

Owner 宁波高新区新柯保汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com