Micro-nano sparkling water treatment device

A water treatment device and technology of micro-nano bubbles, which are applied in the fields of special compound water treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of easy bursting of bubbles, excessive release of dissolved oxygen, and oxygen content in water. Insufficient and other problems, to achieve the effect of slow rising speed, high dissolution efficiency and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and it is defined that the baffle plate B is similar in structure to the baffle plate A.

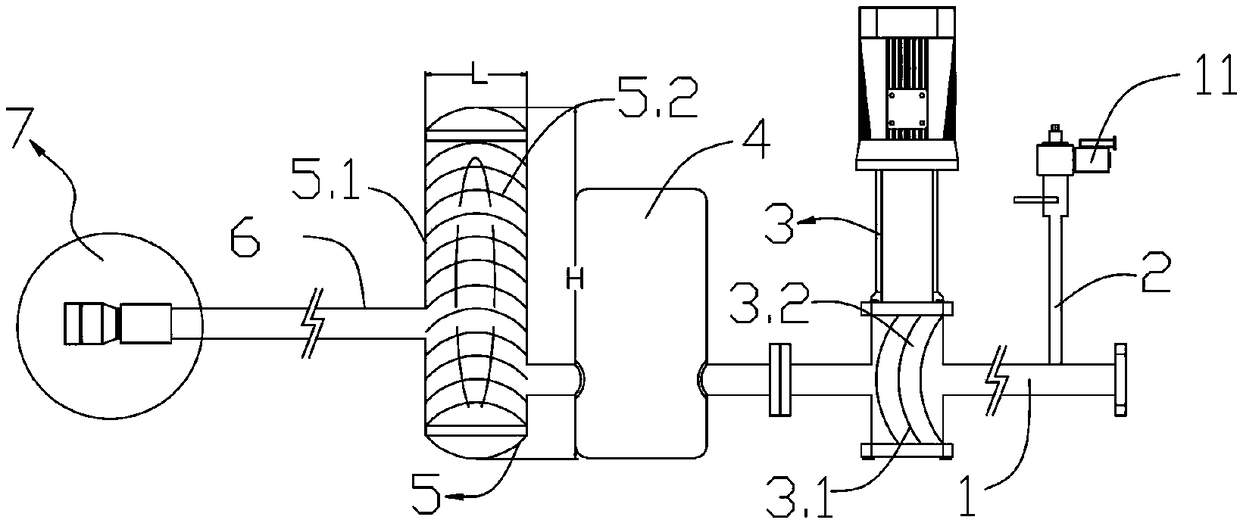

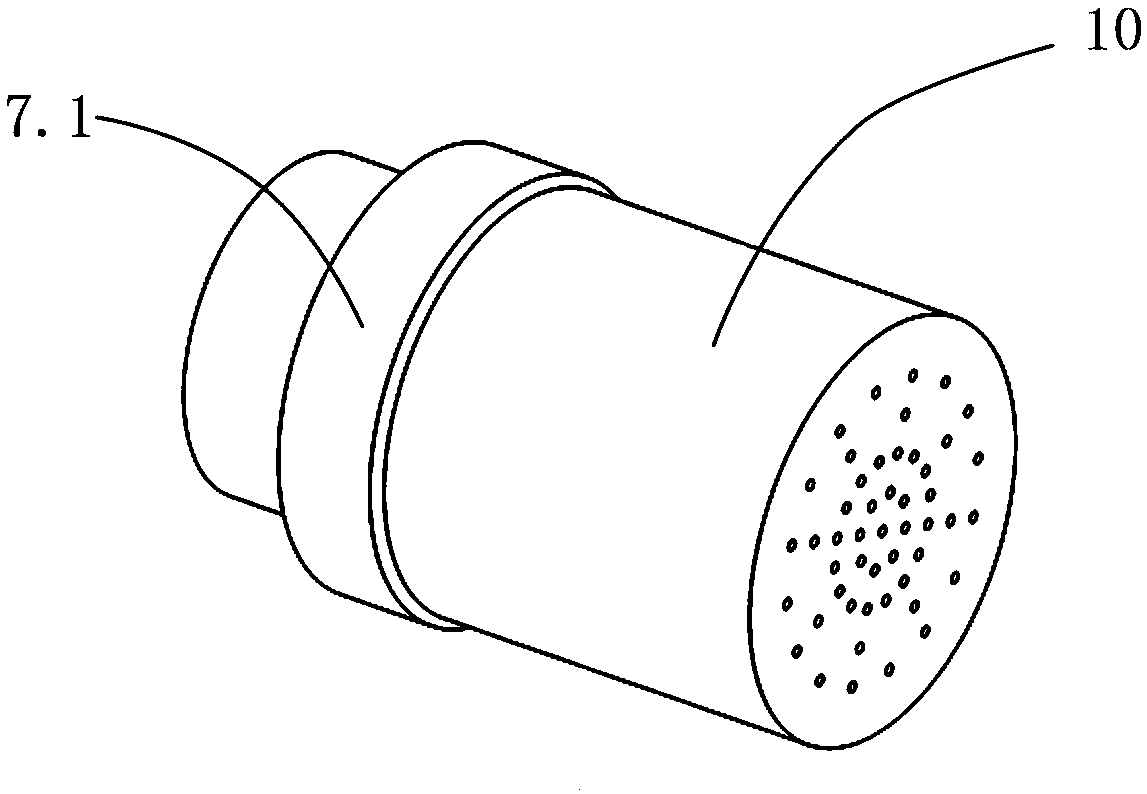

[0031] like figure 1 and figure 2 As shown, a micro-nano bubble water treatment device of the present invention is sequentially provided along the direction from water inlet to water outlet:

[0032] The water inlet pipe 1 is respectively connected to the air inlet pipe 2 and the multi-stage pump body 3. The ratio of the water intake of the water inlet pipe 1 to the air intake of the air inlet pipe 2 is 1:1. and the multi-stage pump body 3 are respectively connected to a controller, and the controller is used to control the opening and closing of the on-off valve 11 and the multi-stage pump body 3;

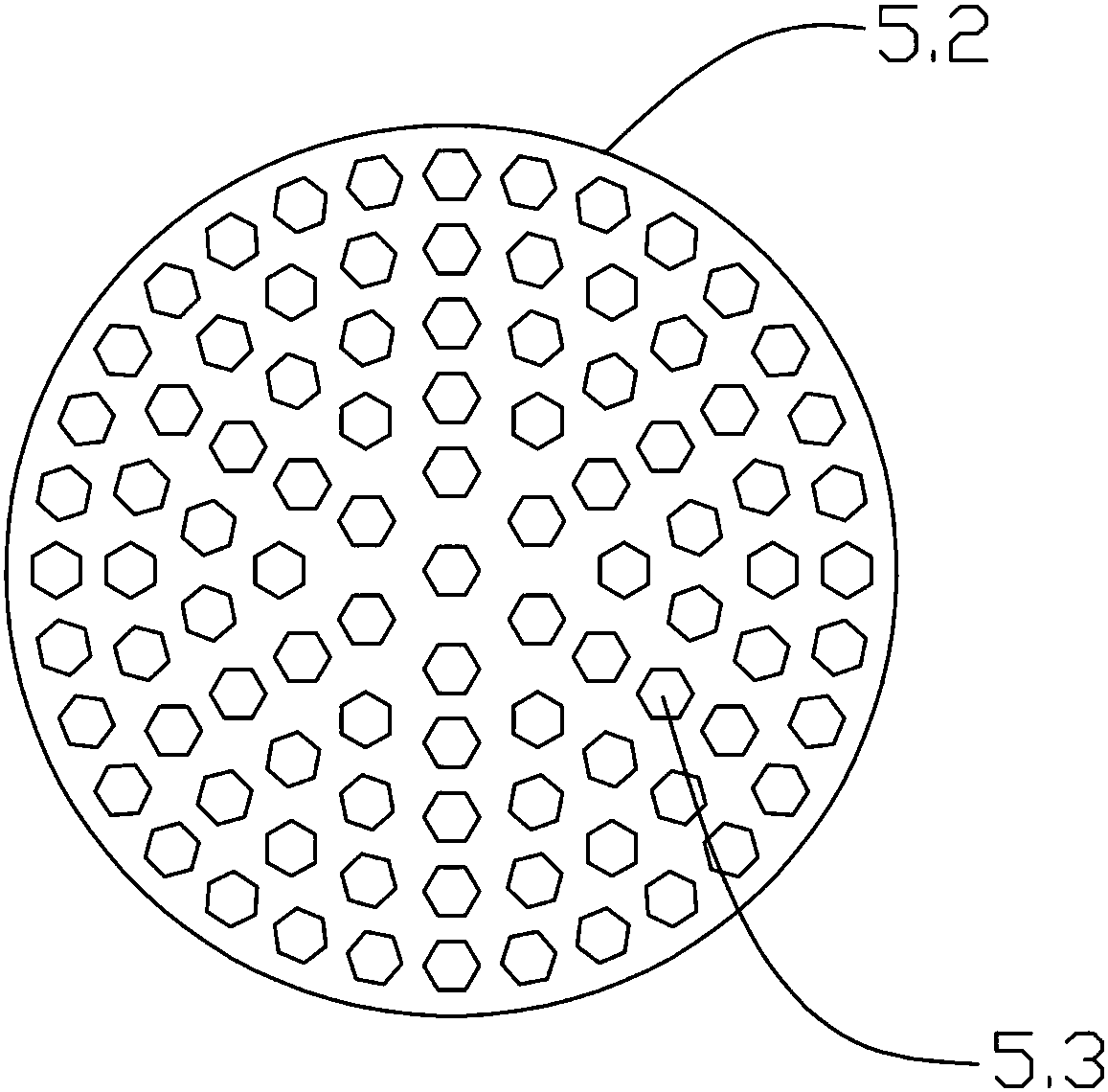

[0033] The mixing chamber 4 includes several opposite inlets and outlets formed on the mixing chamber 4, and each inlet and outlet communicate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com