Bio-based flame-retardant curing agent for epoxy resin as well as preparation method and application thereof

A bio-based technology for epoxy resin, applied in the field of bio-based flame retardant curing agent for epoxy resin and its preparation, to achieve the effects of less by-products, lower production costs and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

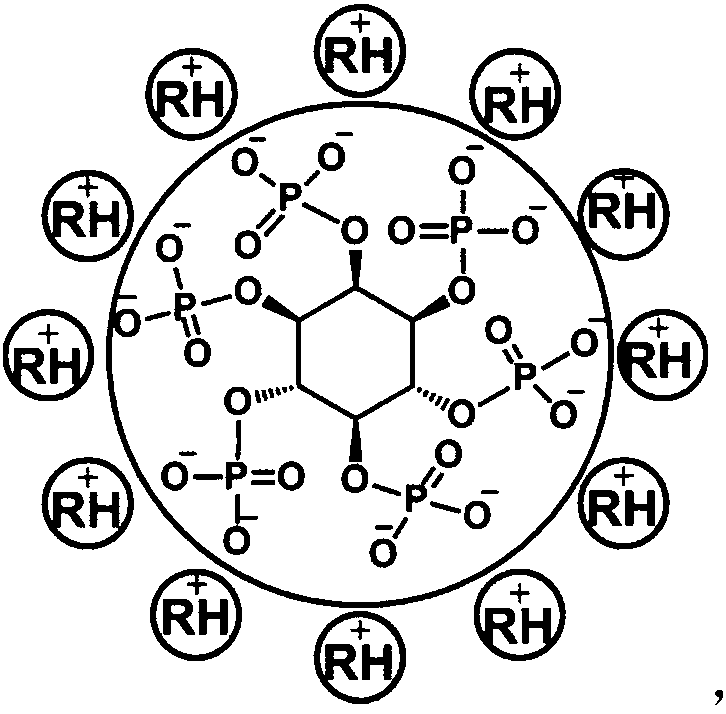

[0030] At room temperature, add 0.05 mol of phytic acid into 50 ml of water, add 0.6 mol of ethylenediamine while stirring, and continue the reaction for 30 minutes after the addition is completed. After the reaction, the solvent water is removed to obtain a white solid powder, which is the final bio-based flame retardant curing agent product, and its structural formula is shown in (1).

[0031]

Embodiment 2

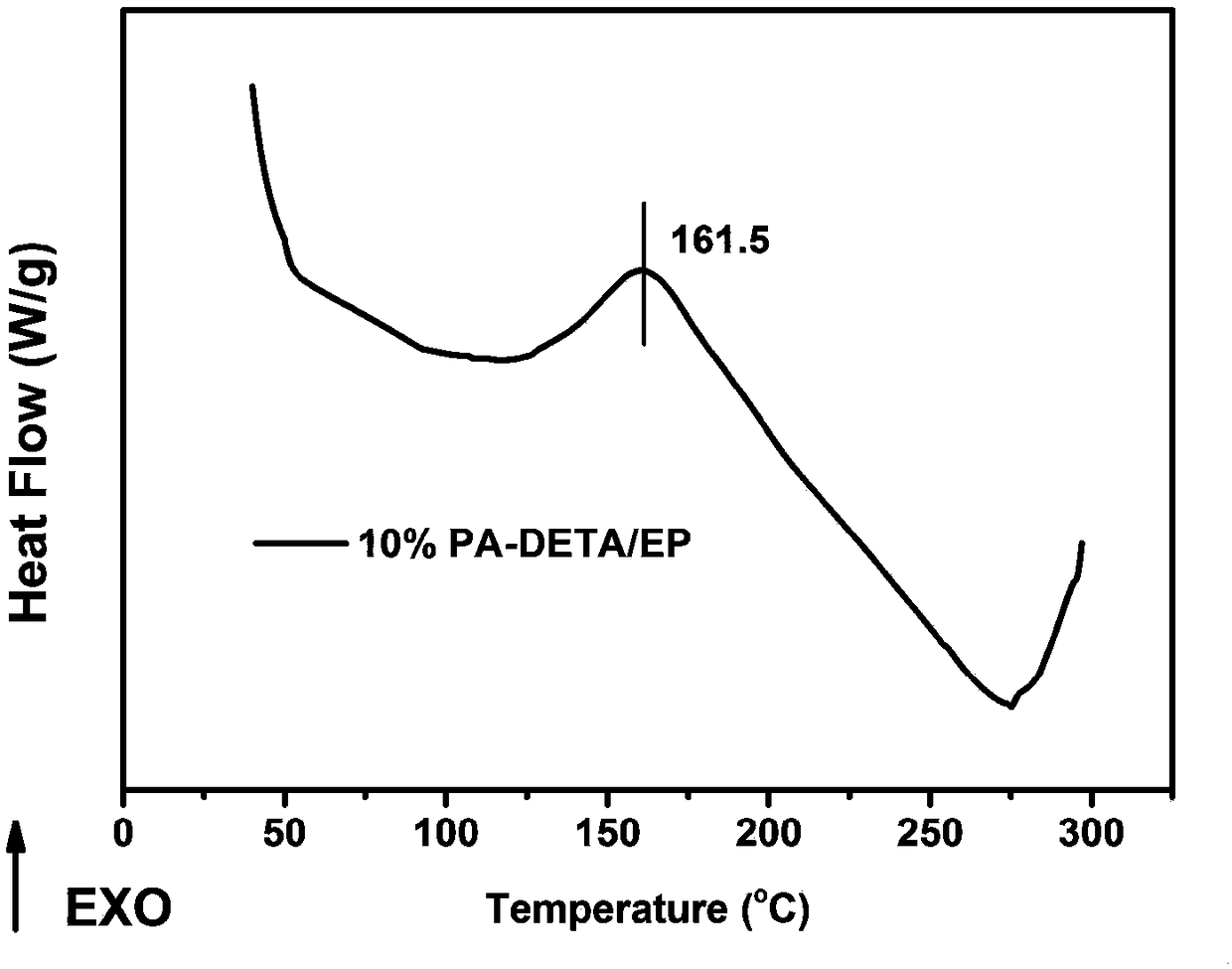

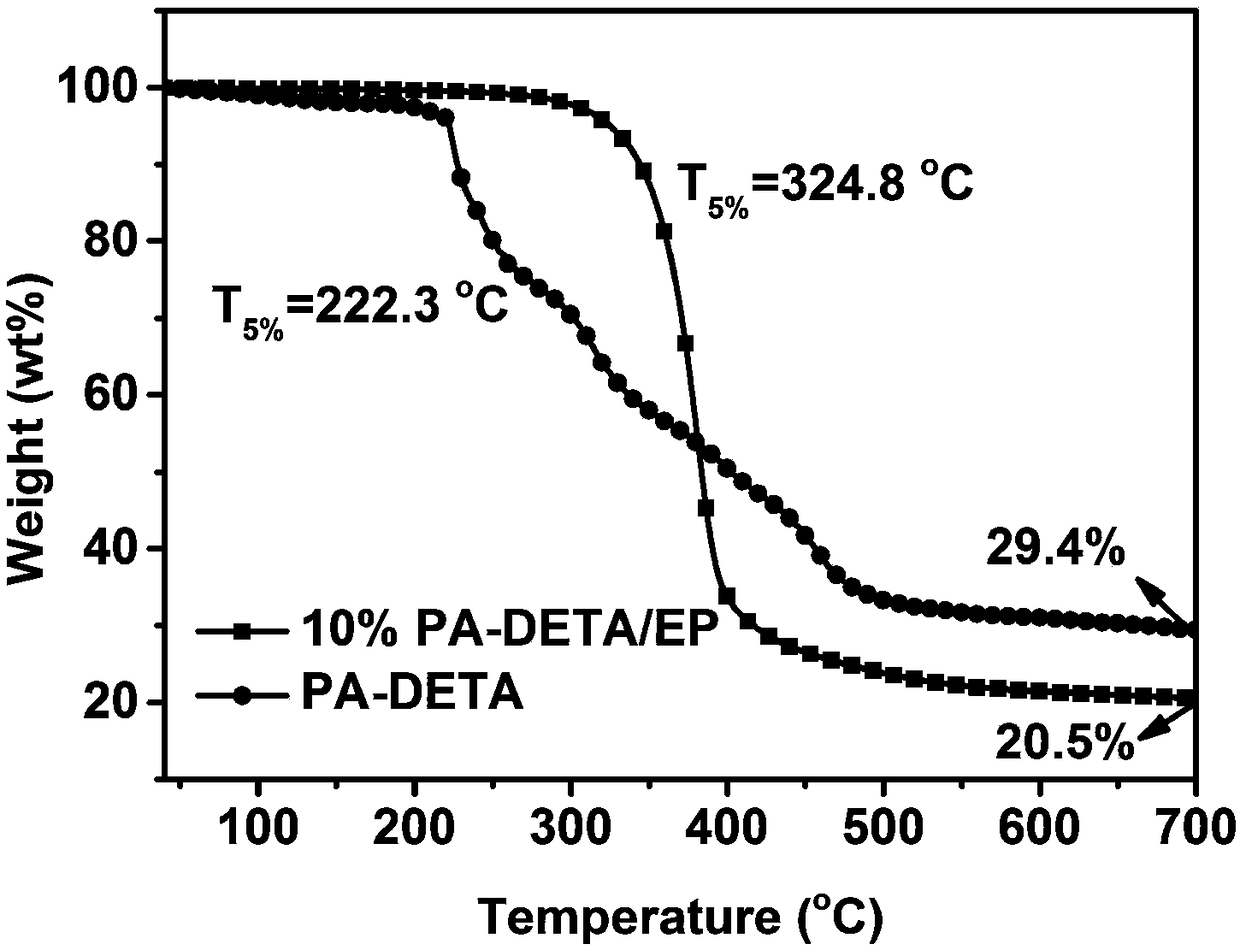

[0033] At 80°C, add 0.05 mol of phytic acid into 50 ml of water, add 0.3 mol of diethylenetriamine (DETA) while stirring, and continue the reaction for 120 minutes after the addition is complete. After the reaction, remove the solvent to obtain a yellow solid The powder is the final bio-based flame retardant curing agent product (PA-DETA), and its structural formula is shown in (2).

[0034]

Embodiment 3

[0036] At 40° C., 0.05 mol of phytic acid was added to 50 ml of methanol, 0.3 mol of triethylenetetramine was added while stirring, and the reaction was continued for 60 minutes after the addition was completed. After the reaction, the solvent is removed to obtain a yellow solid powder, which is the final bio-based flame retardant curing agent product, and its structural formula is shown in (3).

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com