A method for preparing high-strength coal-based isotropic pitch-based carbon fibers

A pitch-based carbon fiber, isotropic technology, applied in fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of low strength of pitch-based carbon fiber, and achieve the effect of large market prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

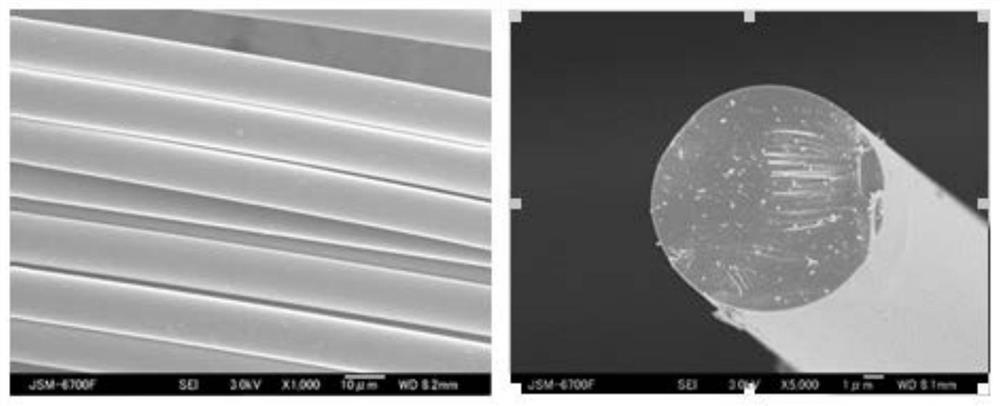

Image

Examples

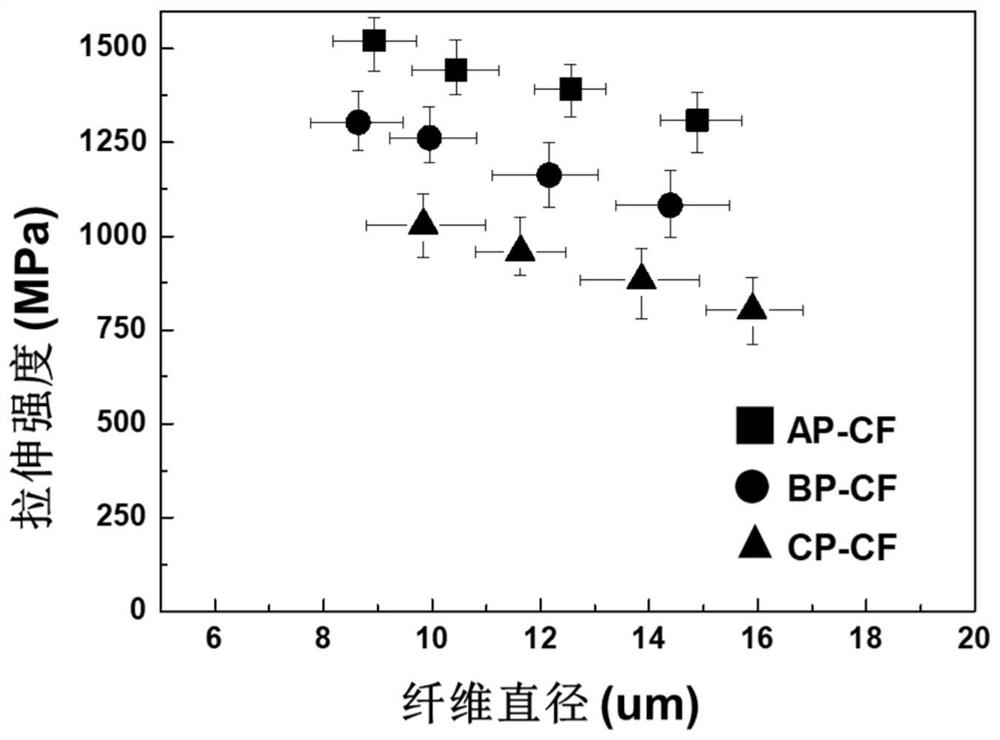

Embodiment 1

[0022] Taking bituminous coal as an example, the method for preparing high-strength coal-based isotropic pitch-based carbon fibers consists of the following steps:

[0023] Preparation of ash-free coal: Mix 100g of bituminous coal with 600g of 1-methylnaphthalene, and react for 3 hours in a high-temperature and high-pressure coal extraction reaction device (designed by ourselves) at 360°C and 2MPa. After the reaction is over, stop stirring, carry out solid-liquid separation and let it stand for 10 minutes, then perform hot-press filtration on three filter plates (5um, 2um, 0.5um), and finally carry out vacuum rotary evaporation at 200°C for the collected filtrate to recover the solvent . Ashless coal A of bituminous coal origin was thus obtained, having an ash content of 147 ppm.

[0024] Preparation of spinning pitch: Ash-free coal A was used as raw material, heat treated at 280°C for 1 hour under vacuum degree of 10Pa to remove its volatile components, and spinning pitch AP...

Embodiment 2

[0030] Taking sub-bituminous coal as an example, the method for preparing high-strength coal-based isotropic pitch-based carbon fibers consists of the following steps:

[0031] Preparation of ash-free coal: 100g of sub-bituminous coal and 800g of 2-methylnaphthalene were mixed, and the reaction was carried out in a high-temperature and high-pressure coal extraction reaction device (designed by ourselves) at 380°C and 3MPa for 3h. After the reaction is over, stop stirring, carry out solid-liquid separation and let it stand for 10 minutes, then perform hot-press filtration on three filter plates (5um, 2um, 0.5um), and finally carry out vacuum rotary evaporation at 200°C for the collected filtrate to recover the solvent . Ashless coal B of sub-bituminous origin was thus obtained with an ash content of 205 ppm.

[0032] Preparation of spinning pitch: Ash-free coal B was used as raw material, heat treated at 300°C for 1.5h under vacuum degree of 10Pa to remove its volatile compone...

Embodiment 3

[0038] Taking lignite as an example, the method for preparing high-strength coal-based isotropic pitch-based carbon fibers consists of the following steps:

[0039] Preparation of ash-free coal: Mix 100g of lignite and 1000g of 2-methylanthracene, and react for 3h at 410°C and 3MPa in a high-temperature and high-pressure coal extraction reaction device (designed by ourselves). After the reaction is over, stop stirring, carry out solid-liquid separation and let it stand for 10 minutes, then perform hot-press filtration on three filter plates (5um, 2um, 0.5um), and finally carry out vacuum rotary evaporation at 200°C for the collected filtrate to recover the solvent . A lignite-derived ash-free coal C having an ash content of 275 ppm was thus obtained.

[0040] Preparation of spinning pitch: Ash-free coal C was used as raw material, heat treated at 280°C for 3 hours under a vacuum of 10Pa to remove its volatile components, and spinning pitch CP with a softening point of 210°C w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com