Reconstruction method of inter-embedded jet grouting in limestone aquifer

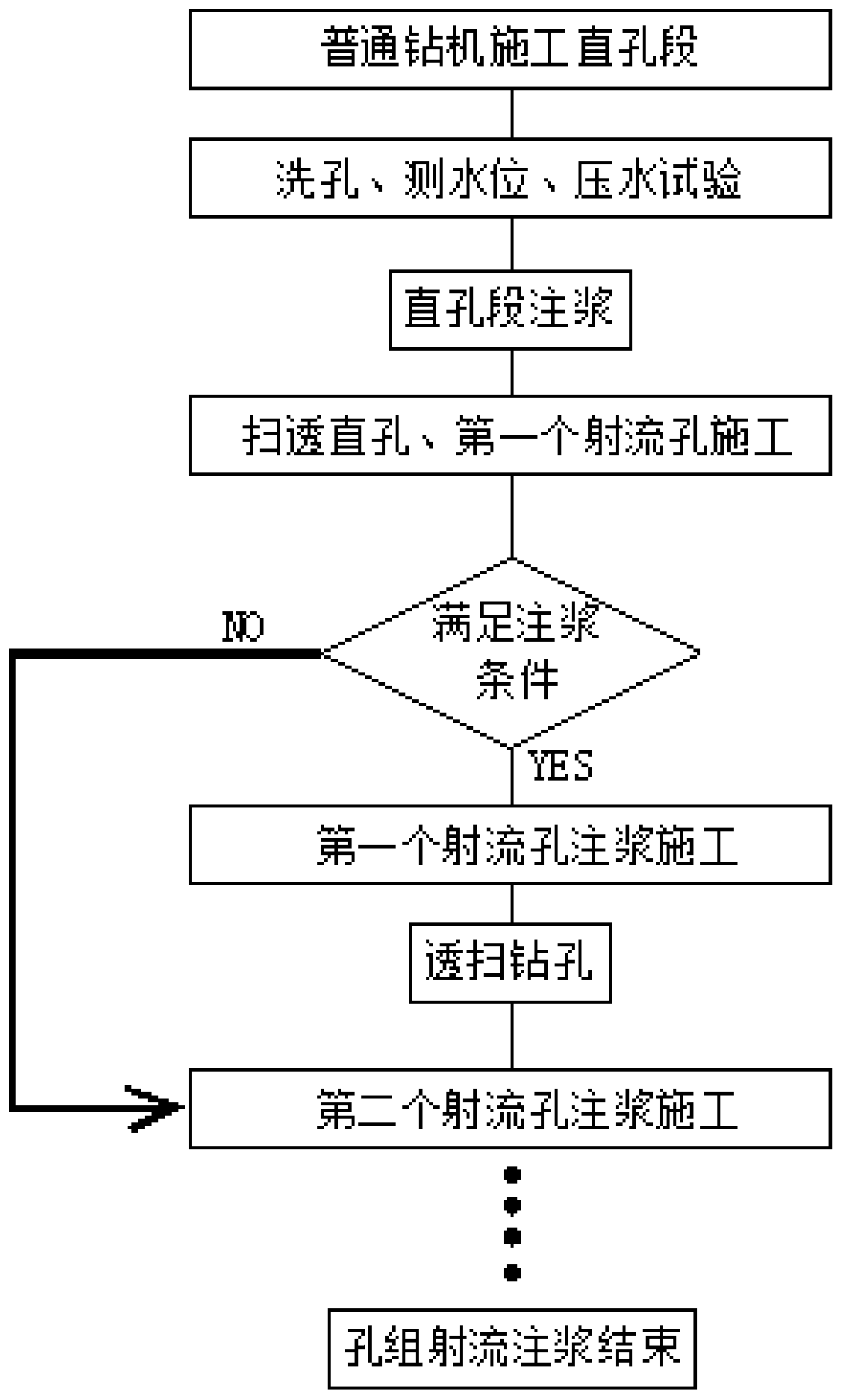

An inter-embedded grouting technology, which is applied in earth square drilling, liquid/gas jet drilling, wellbore/well components, etc., can solve problems such as advanced grouting in shallow coal seams and difficult ground in complex structural areas. Achieve the effects of good grouting transformation effect, low cost and high effective hole section rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

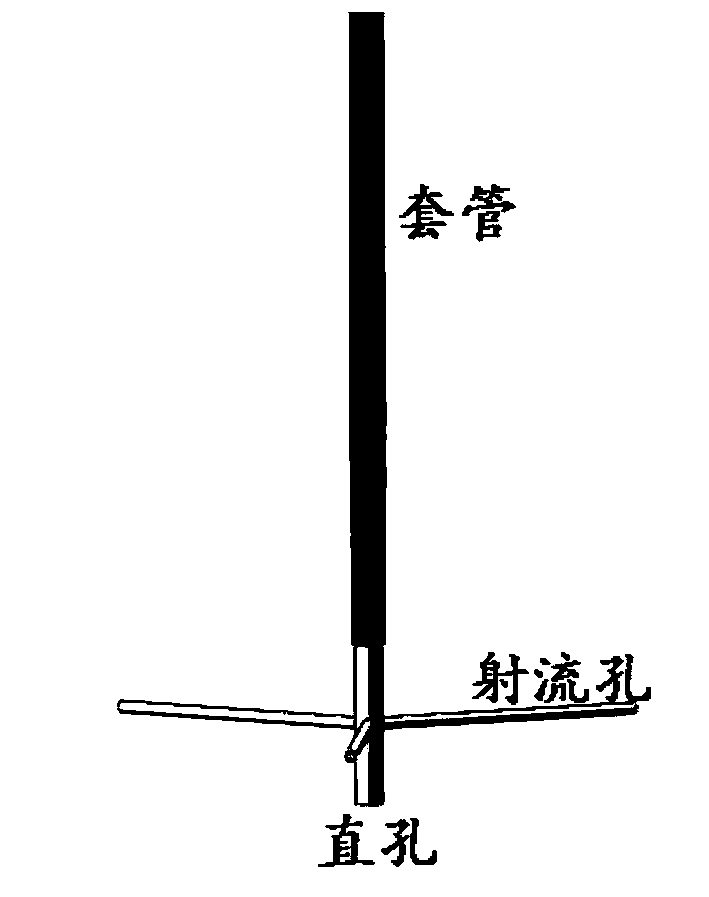

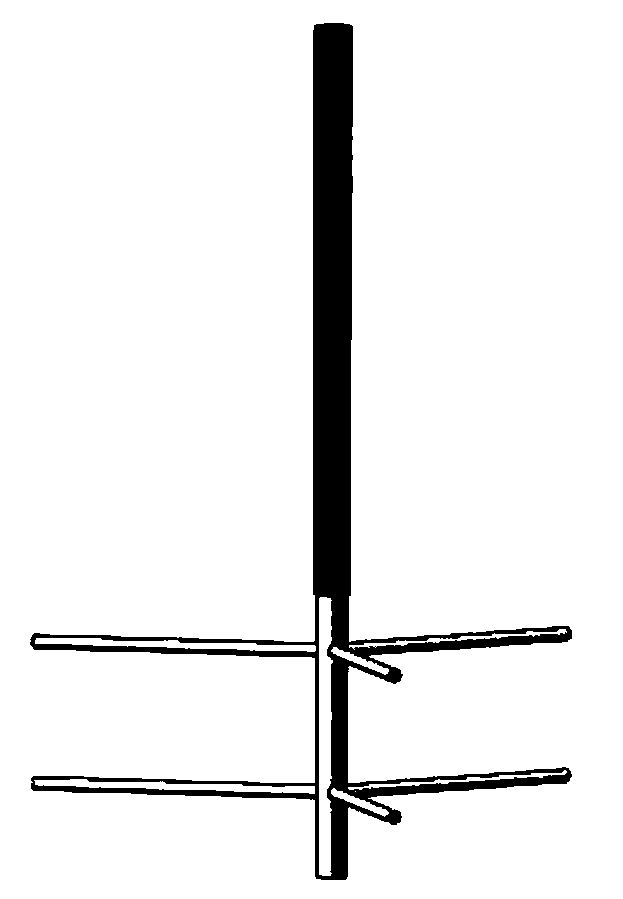

[0044] Taking a mine in Xingtai, Hebei Province as an example, Austrian ash is an indirect water-filled aquifer mined from the coal seam. The average hydraulic pressure of the Austrian ash on the floor of the coal seam in the area of the first mining area is 2.31MPa, and the average distance between the coal seam and the Austrian ash aquifer is 32.12m. There are many internal faults, and coal seam mining is greatly threatened by Austrian ash water. The inter-embedded jet grouting project is arranged on the ground, and a comprehensive grouting transformation is carried out on the top surface of the bottom plate of the first mining area.

[0045] Step 1: Straight hole section construction. The drilling volume of the first straight hole (D1) is 265.54m. The loose layer is drilled without core, and the bedrock section is drilled with core. The thickness of the alluvial layer is 173.25m, and the final hole enters Austrian ash 16.38m. The diameter of the first hole is Φ245mm, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com