Waste-heat recycling device for cooling industrial oil

A waste heat recovery device and industrial oil technology, applied in the direction of filtration circuit, indirect heat exchanger, heat exchanger type, etc., can solve the problems of reducing the working efficiency of industrial oil processing, wasting time and cost, and environmental damage, etc., to increase Production quality, avoidance of environmental pollution, effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

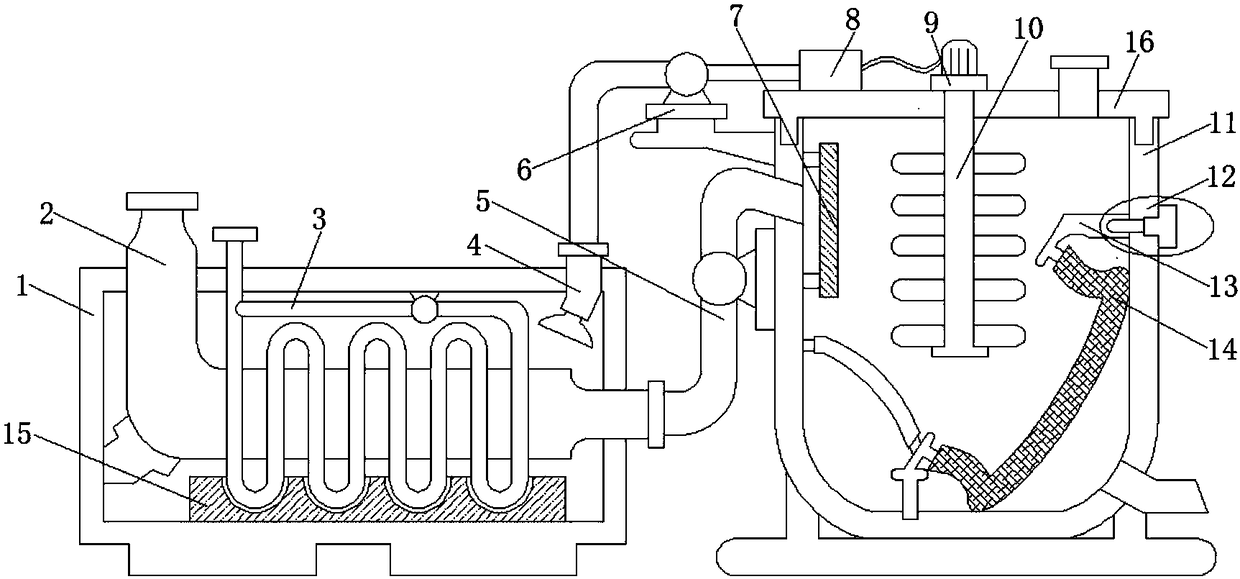

[0018] Example 1: Reference Figure 1-3 , a waste heat recovery device for industrial oil cooling, the cooling liquid is injected into the cooling water pipe 3 through the inlet of the cooling water pipe 3 exposed at the outer end of the cooling box 1, and under the action of the circulating pump connected to the upper end, the cooling liquid can be The cooling water pipe 3 circulates in circulation, and then the industrial oil that needs to be cooled is injected into the circulation pipe 2 through the open end of the circulation pipe 2, so that the high-temperature industrial oil flows through the circulation pipe 2 to the next connected pipe. When flowing in the circulation pipe 2, the cooling water pipe 3 wrapped around the outer wall of the circulation pipe 2 will cool the oil in the circulation pipe 2, and the cooling liquid will circulate in the cooling water pipe 3 to generate cold air and oil in the circulation pipe 2. The steam generated by the liquid undergoes heat e...

Embodiment 2

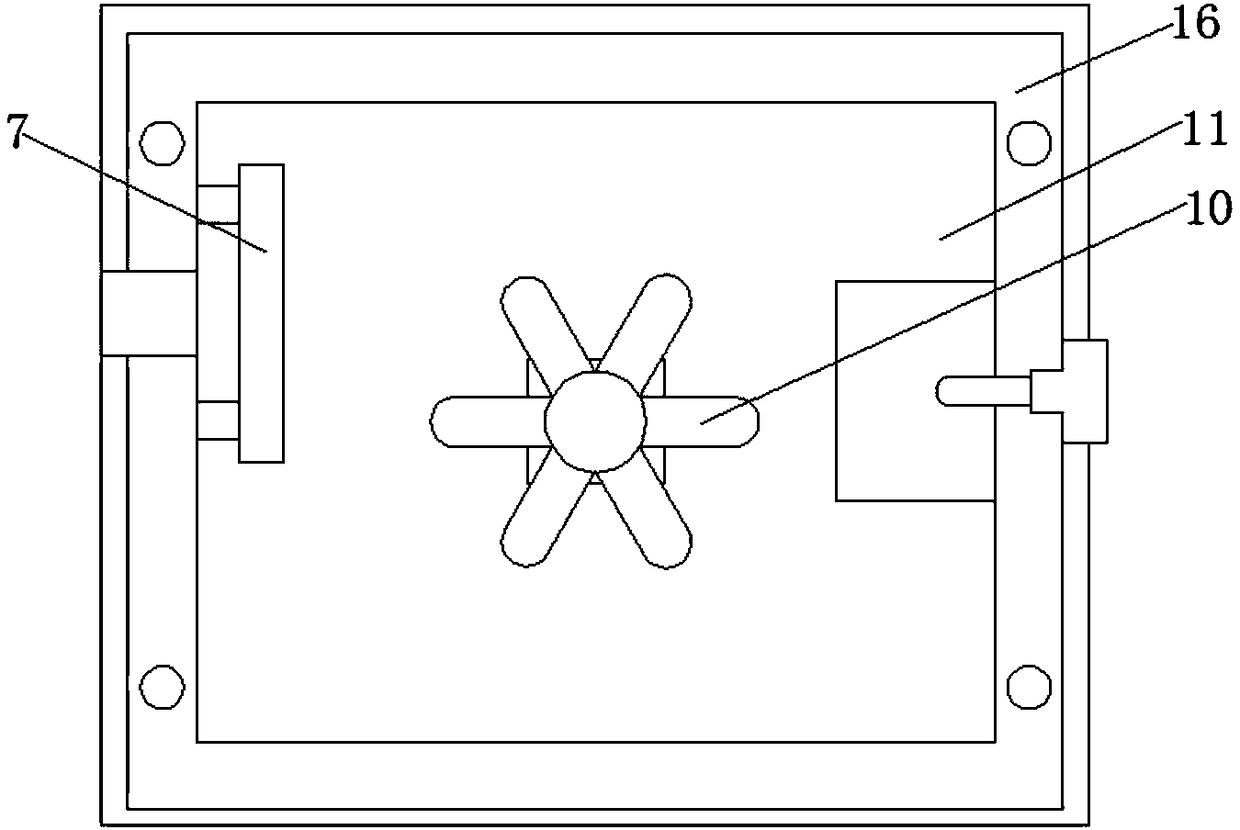

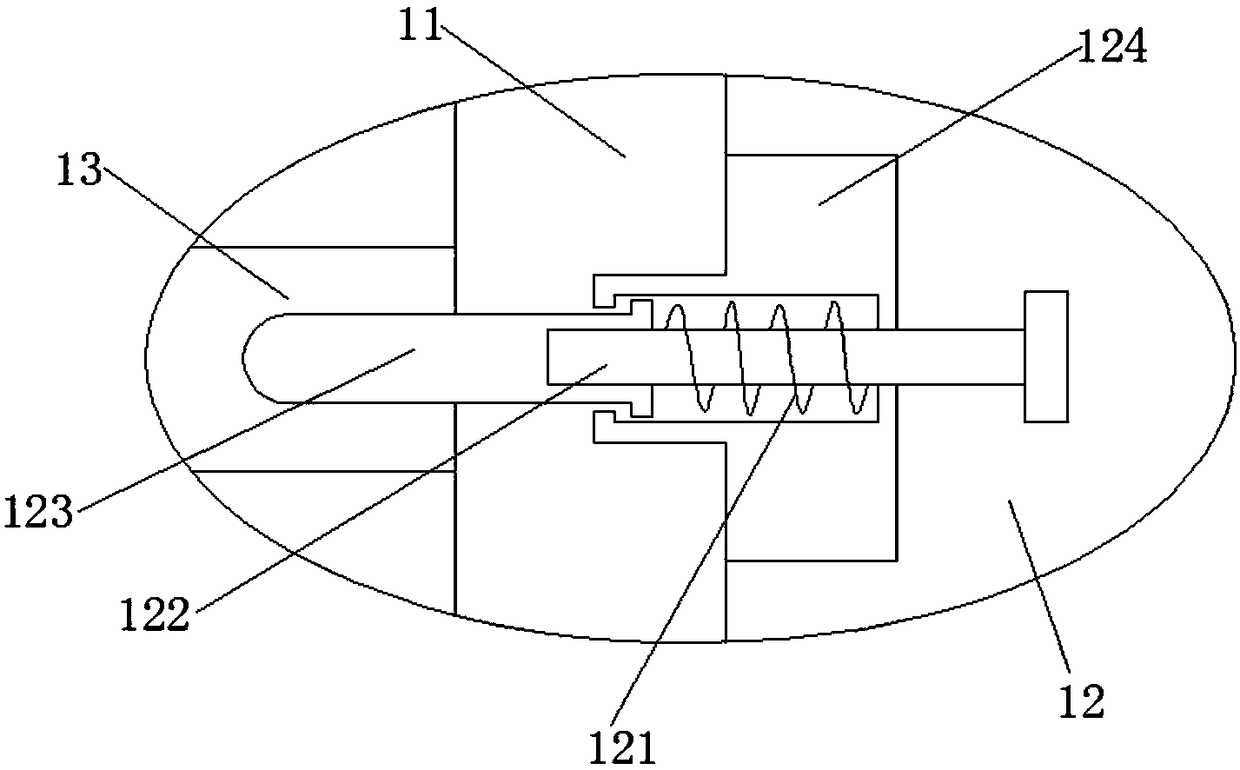

[0019] Example 2: Reference Figure 1-3 , a waste heat recovery device for cooling industrial oil, when the filter box 11 and the adsorption net 14 in the filter box 11 need to be disassembled and cleaned, the sealing cover 16, the motor 9 and the stirring paddle 10 need to be removed from the filter box 11 first. Since the filter screen 7 is clamped in the filter box 11, it can be quickly disassembled, and then manually pull the stretching rod 122, because the stretching rod 122 is threaded into the limit rod 123, so the movement of Detach the compression spring 121 of the driving limit rod 123 from the connecting plate 13, and then manually take out the guide plate, auxiliary rod, adsorption net 14 and connecting plate 13 from the filter box 11, which improves the protection of the filter screen 7, the adsorption net 14 and the connection plate 13. The cleaning of the filter box 11 is convenient and quick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com