Ultrathin direct type backlight module

A backlight module and direct-type technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of backlight module and display such as large thickness, heat accumulation, and restricted development, so as to improve the utilization rate of light energy and uniform illuminance performance, reduce the difficulty of processing and installation, and reduce the effect of light mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

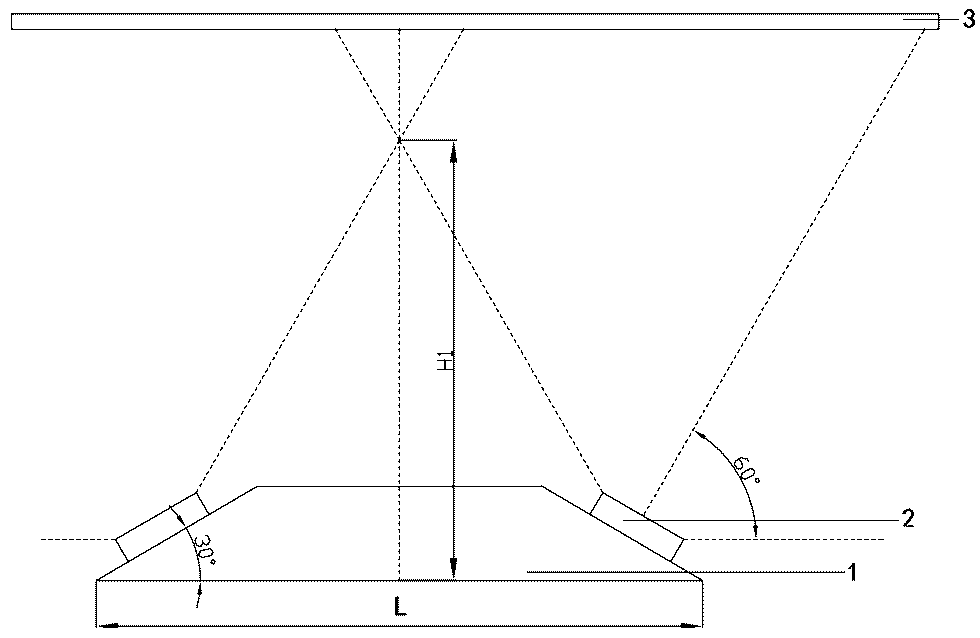

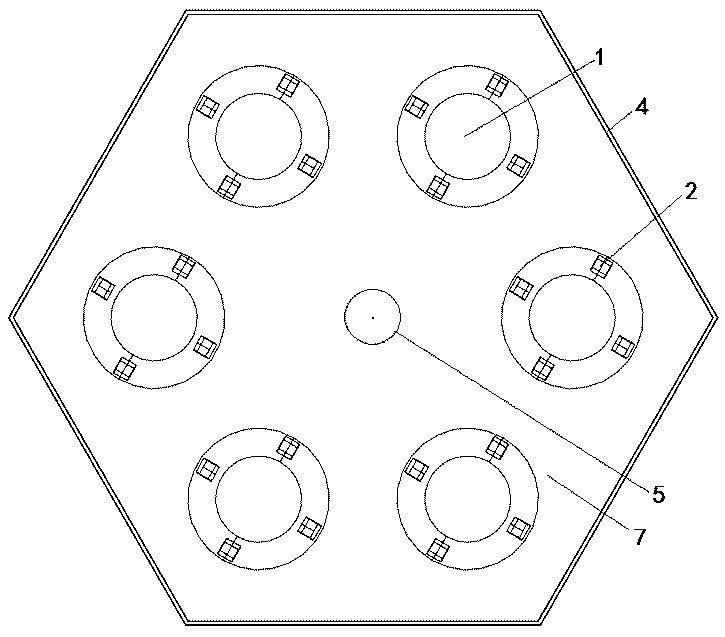

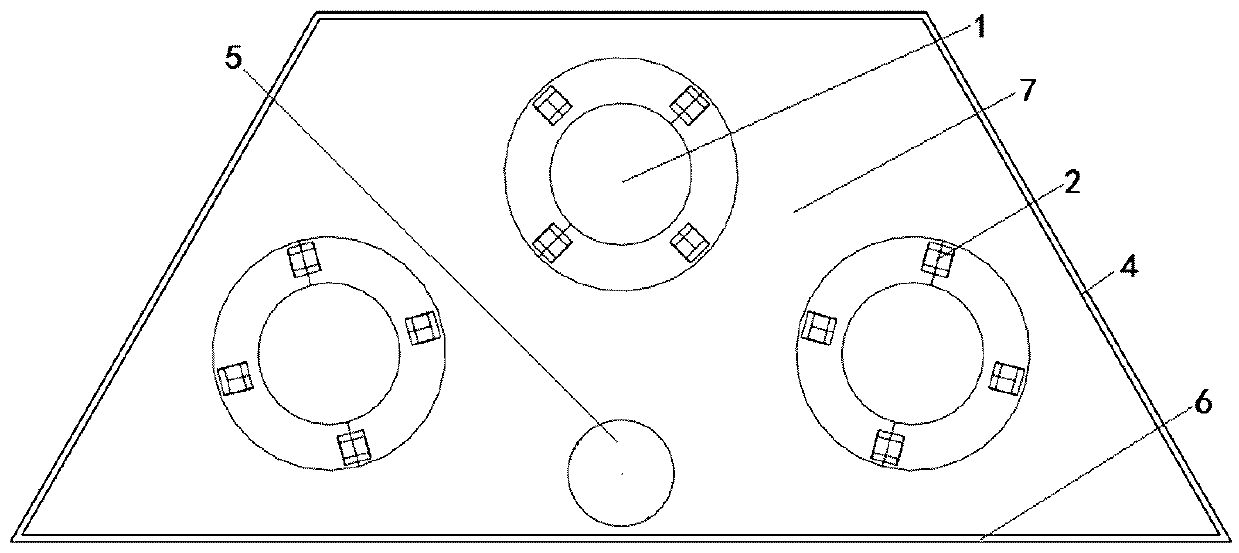

[0023] The application will be further described in detail below with reference to the accompanying drawings: an ultra-thin direct-lit backlight module, including multiple round tables, multi-section reflective partitions, LED lamp beads, cones, a bottom plate, and a frame.

[0024] The size of the round platform used in the embodiment is: the diameter L of the bottom surface is 17.32mm, the inclination angle is 30°, and at least LED lamp beads can be placed on the side, such as figure 1 ; Due to the precise design of the size of the round table, the LED lamp beads are placed on the side of the round table, changing the outgoing direction of the light at the center of the maximum light intensity. The light mixing distance reduces the thickness of the liquid crystal display.

[0025] The LED lamp beads used in this example are produced by CREE Company, the model is XLamp XQ-A, and the bottom surface size is 1.6 1.6mm, the luminous flux of a single LED is 89 lm. Evenly place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com