A hydrofining catalyst and a preparing method and application therefor

A hydrofining and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low activity of hydrofining catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] According to the preparation method of the hydrotreating catalyst provided by the present invention, the preparation method comprises the following steps:

[0020] (1) impregnating the carrier with the first impregnating liquid, then drying and roasting to obtain a semi-finished catalyst, the roasting conditions are such that the carbon content in the semi-finished catalyst is 0.03-0.5% by weight based on the total amount of the semi-finished catalyst; (2) The second impregnating liquid impregnates the semi-finished catalyst obtained in step (1), then drying and not roasting;

[0021] Wherein, the first impregnating liquid is an acidic aqueous solution containing a water-soluble salt of a hydrogenation active metal component and an organic complexing agent, and the second impregnating liquid is an alkaline aqueous solution containing an organic complexing agent.

[0022] According to the present invention, preferably, the roasting condition described in step (1) is such...

Embodiment approach

[0061] According to a preferred embodiment of the present invention, the inorganic heat-resistant oxide is alumina, and more preferably the carrier is alumina and a macroporous molecular sieve (ie, alumina-macroporous molecular sieve). Among them, alumina is more preferably alumina obtained after firing a hydrated alumina (aluminum hydroxide) colloidal compound.

[0062] According to a preferred embodiment of the present invention, the radial crushing strength of the carrier is 20-40N / mm, the water absorption is 0.65-1.3mL / g, the pore volume is 0.4-0.9mL / g, and the specific surface area is 200-350m 2 / g.

[0063] In the present invention, the measuring method of the water absorption rate of catalyst carrier is: the carrier (by weight) is immersed in water (by volume) for 2 hours, the ratio of carrier (by weight g) to water (by volume mL) The ratio is 1:3, and then the carrier after water absorption is separated from the water, and the water absorption volume of the carrier is...

Embodiment 1

[0083] This example is used to illustrate the hydrorefining catalyst and its preparation method according to the present invention.

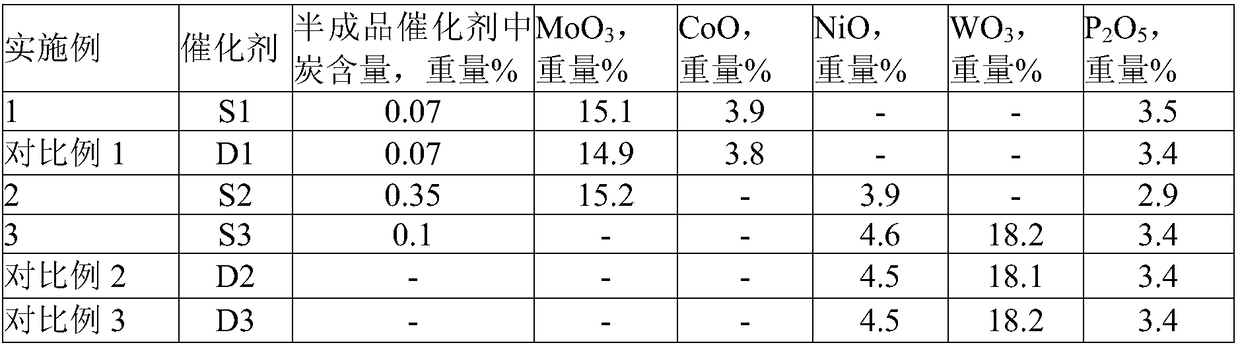

[0084] Weigh 40 grams of molybdenum trioxide, 19 grams of basic cobalt carbonate, 15 grams of phosphoric acid, and 20 grams of citric acid into 140 grams of deionized water, heat and stir to dissolve to obtain a clear impregnation solution, and the measured pH is 3.5. Using the saturated impregnation method to impregnate 200 grams of alumina carrier Z1 with the above solution, the impregnation time is 2 hours, then dry at 120°C for 2 hours, and then roast it under the state of feeding air flow, the roasting temperature is 400°C, The time is 2 hours, with respect to every gram of carrier, the air feeding rate is 2 liters / hour, obtains semi-finished catalyst Z1-S1, and the carbon content of Z1-S1 is shown in Table 1; 5 grams of EDTA are added in 150 grams of deionized water, add Adjust the pH value of the solution to 10.5 with an appropriate amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com