Rail track friction welding method

A friction welding and friction welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large fluctuations in joint quality, poor comprehensive performance, and unstable quality, and achieve stable joint quality and high thermal efficiency , The effect of less machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

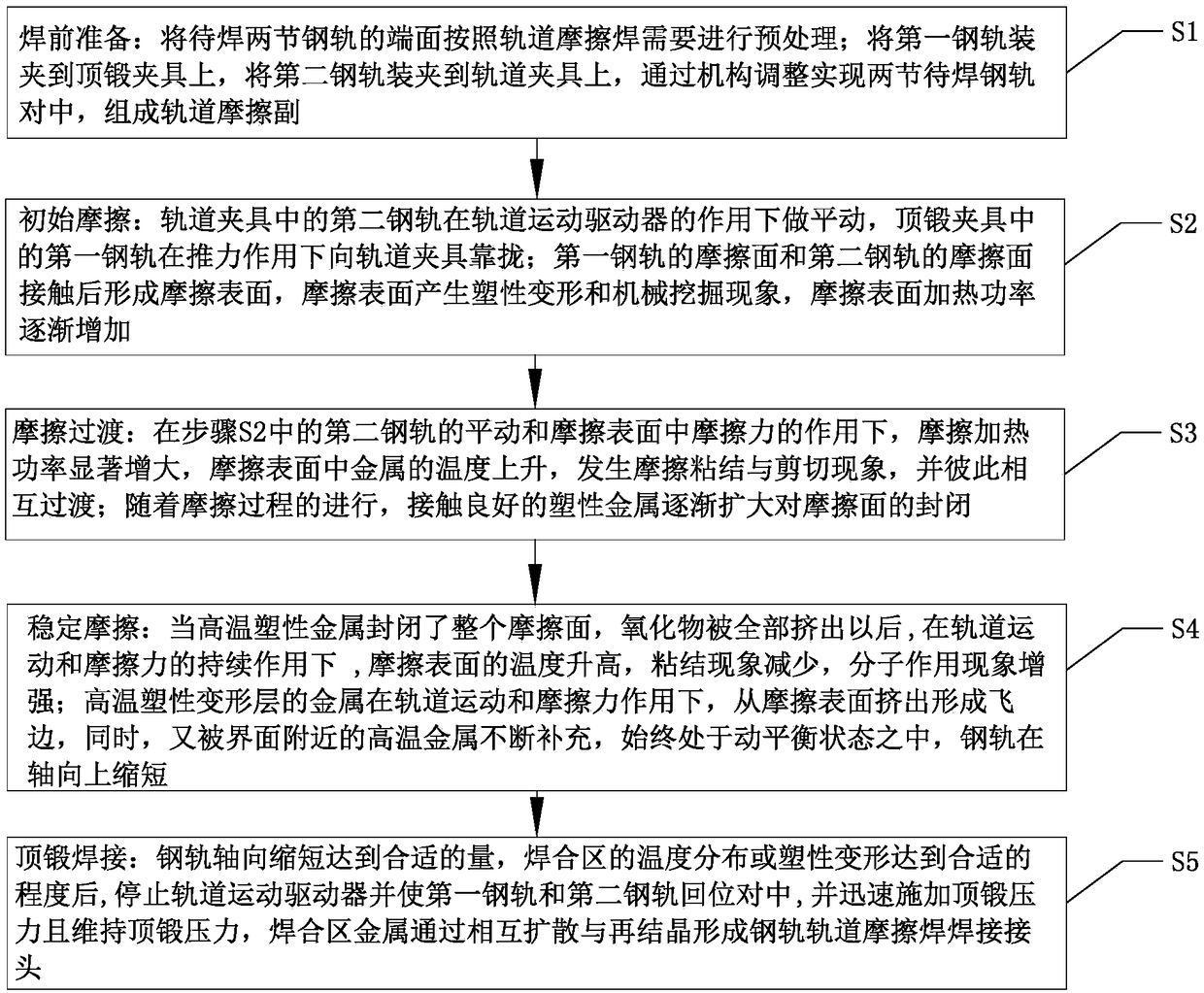

[0033] Such as figure 1 As shown, a kind of rail track friction welding method provided by the invention comprises the following steps:

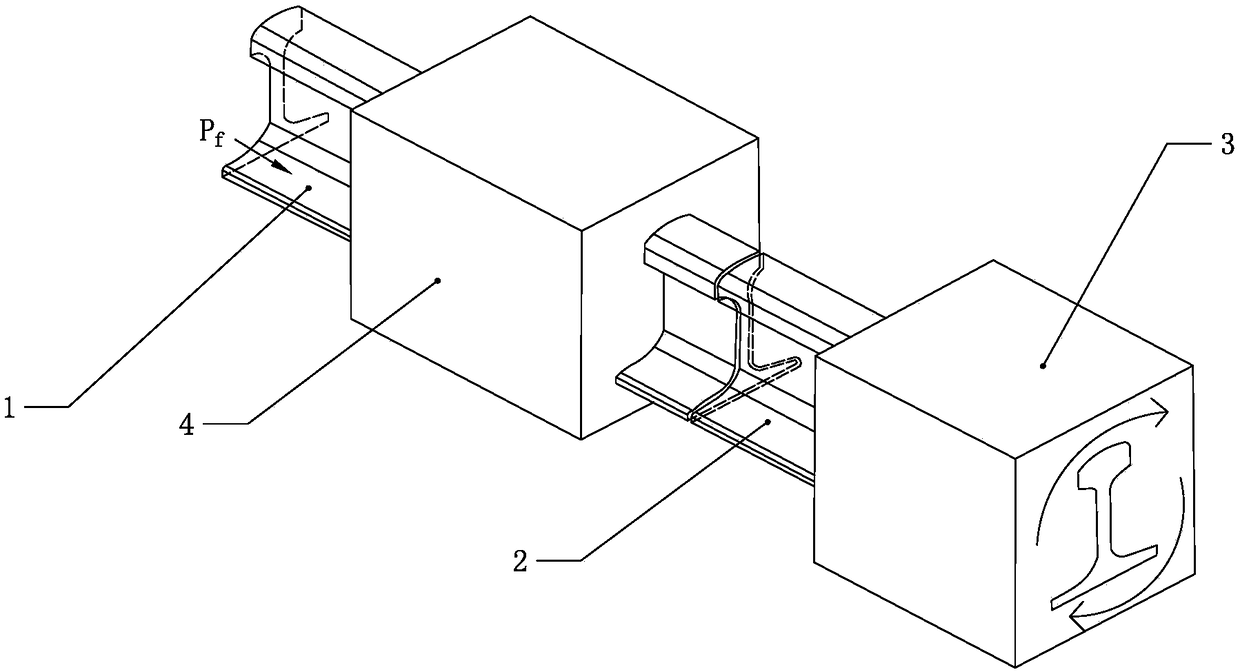

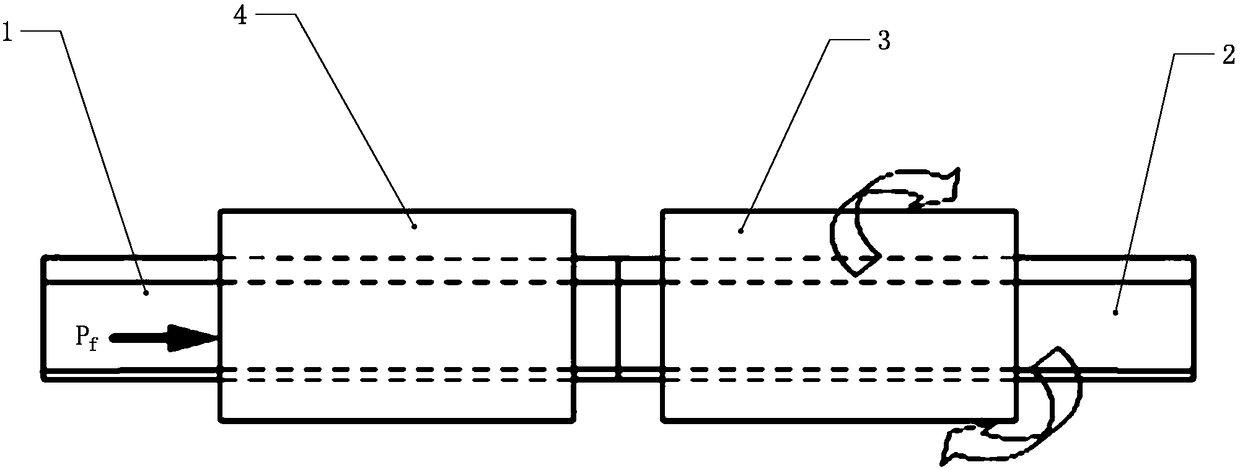

[0034] S1. Preparation before welding: pre-treat the end faces of the two rails to be welded according to the requirements of orbital friction welding; clamp the first rail 1 to the upsetting fixture 4, clamp the second rail 2 to the rail fixture 3, and pass The mechanism adjustment realizes the alignment of the two rails to be welded to form a rail friction pair.

[0035] The first steel rail 1 and the second steel rail 2 have the same structure, and the end face of the first steel rail 1 is perpendicular to the extension line of the first steel rail 1 itself. The rail clamp 3 can clamp the second rail 2 and make the second rail 2 move in translation along a predetermined track. The track is also called the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com