Preparation method of 3,5-dibromopyridine

A technology of dibromopyridine and pyridine, which is applied in the field of synthesis of chemical raw materials, can solve the problems of high requirement of conditions, many pollutions of three wastes, cumbersome steps, etc., and achieve the effect of high reaction yield, good reaction effect and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

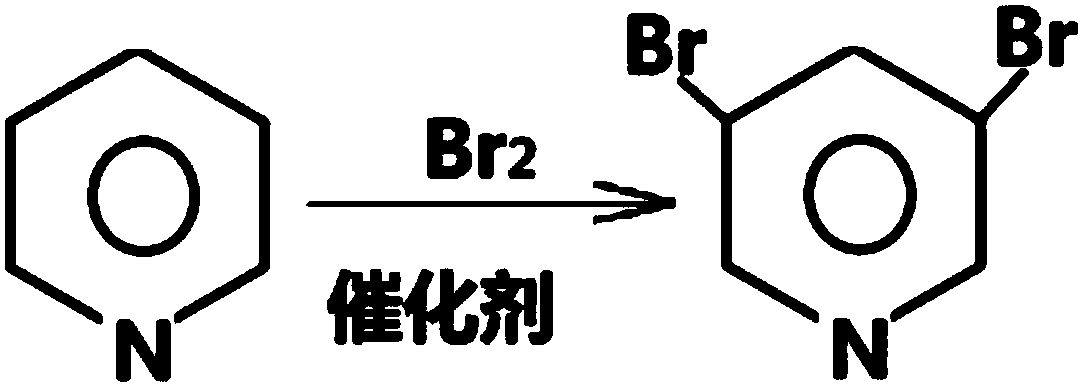

[0033] Such as figure 1 Shown, the present invention provides a kind of simple and easy preparation method of 3,5-dibromopyridine, with pyridine as raw material, with concentrated sulfuric acid and thionyl chloride as catalyzer, under high temperature condition (high temperature refers to temperature at 125- 138 ℃) under the dropwise addition of bromine reaction. Concrete reaction steps are:

[0034] (1) 100g pyridine is added in 100g vitriol oil and 300g sulfur oxychloride, heat up and reflux, the massfraction of vitriol oil is 98%;

[0035] (2) Add 550g of bromine dropwise under reflux (completely dropwise within 10 hours), heat up to 130°C for reaction, observe whether there is reddish-brown gas in the reaction test tube to judge whether the reaction is complete;

[0036] (3) The reaction solution is subjected to steam distillation, and the product precipitated in water is crude 3,5-dibromopyridine, which does not need to be dried, and then the crude 3,5-dibromopyridine i...

Embodiment 2

[0049] Such as figure 1 Shown, the present invention provides a kind of simple and easy preparation method of 3,5-dibromopyridine, with pyridine as raw material, with concentrated sulfuric acid and thionyl chloride as catalyzer, under high temperature condition (high temperature refers to temperature at 125- 138 ℃) under the dropwise addition of bromine reaction. Concrete reaction steps are:

[0050] (1) 100g pyridine is joined in 100g vitriol oil and 250g sulfur oxychloride, heats up and refluxes, and the massfraction of vitriol oil is 99%;

[0051](2) Add 500g of bromine dropwise under reflux (completely drop within 12 hours), raise the temperature to about 125°C for reaction, observe whether there is reddish-brown gas in the reaction test tube to judge whether the reaction is complete;

[0052] (3) The reaction solution is subjected to steam distillation, and the product precipitated in water is crude 3,5-dibromopyridine, and then the crude 3,5-dibromopyridine is dissolve...

Embodiment 3

[0062] Such as figure 1 Shown, the present invention provides a kind of simple and easy preparation method of 3,5-dibromopyridine, with pyridine as raw material, with concentrated sulfuric acid and thionyl chloride as catalyzer, under high temperature condition (high temperature refers to temperature at 125- 138 ℃) under the dropwise addition of bromine reaction. Concrete reaction steps are:

[0063] (1) 100g pyridine is added in 100g concentrated sulfuric acid and 300g sulfur oxychloride, heat up and reflux, the massfraction of concentrated sulfuric acid is 99.5%;

[0064] (2) Add 700g of bromine dropwise under reflux (completely add dropwise within 10 hours), heat up to 138°C for reaction, observe whether there is reddish-brown gas in the reaction test tube to judge whether the reaction is complete;

[0065] (3) The reaction solution is subjected to steam distillation, and the product precipitated in water is crude 3,5-dibromopyridine, and then the crude 3,5-dibromopyridin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap