In-situ composite loading and measuring device for micro-nano samples

An in-situ composite and measuring device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of large size and complex structure of the multi-functional in-situ mechanical testing platform, and achieve good structural compatibility, small size and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

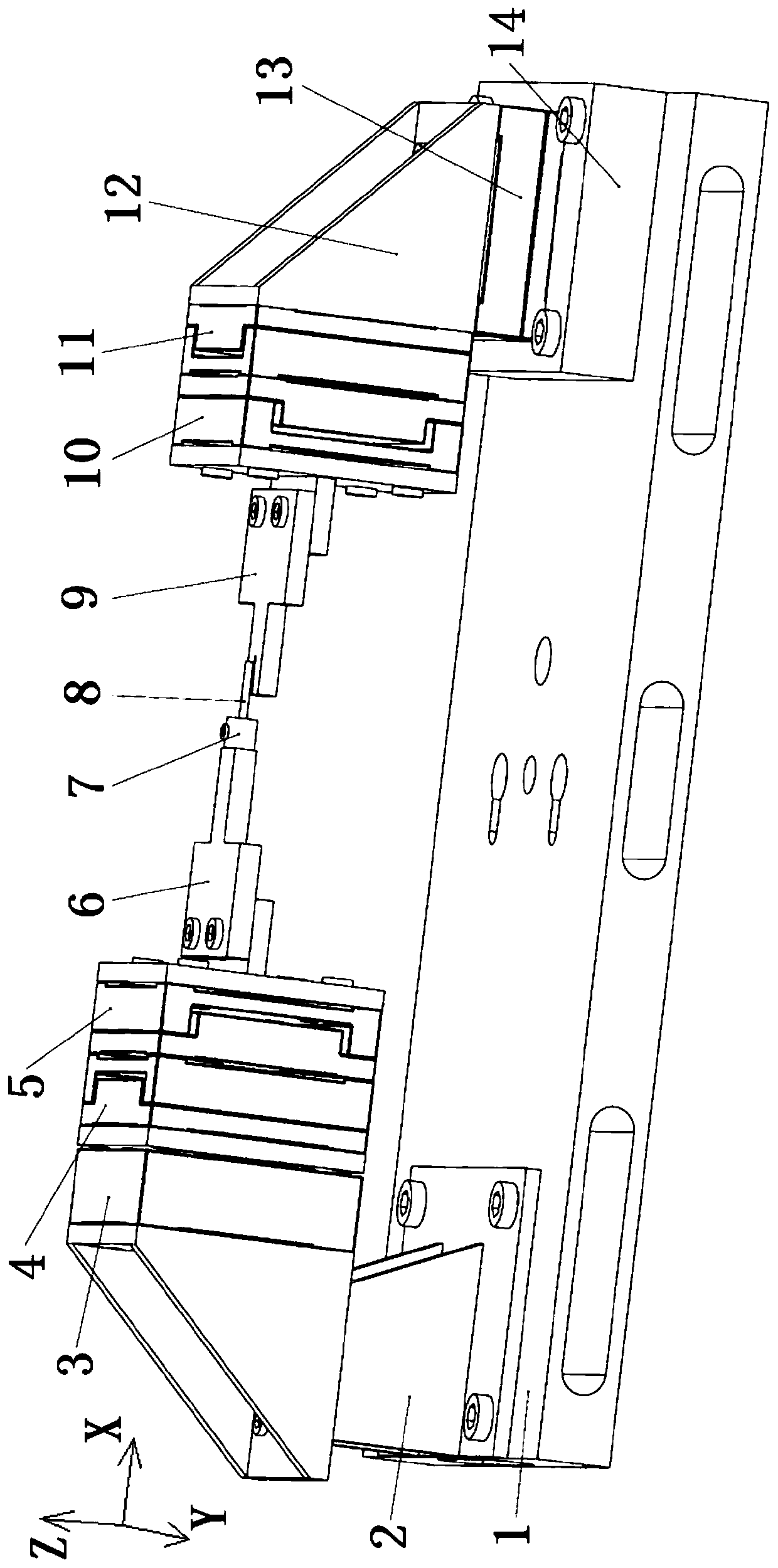

[0017] An in-situ composite loading and measuring device for micro-nano samples, in a space Cartesian coordinate system with X, Y, and Z as coordinate axes, the in-situ composite loading and measuring device for micro-nano samples includes The left loading adjustment assembly and the right loading adjustment assembly are arranged in sequence in the positive direction of the coordinate axis. The left loading adjustment assembly includes a left rotary piezoelectric ceramic motor 3, a left vertical linear piezoelectric motor, and a left vertical linear piezoelectric motor connected sequentially along the positive direction of the X coordinate axis. The ceramic motor 4 and the left horizontal linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com