On-line constant temperature detection method of welding arc pollutants based on emission spectrum

A detection method and emission spectrum technology, which is applied in the field of environmental impact detection of welding processing, can solve the problems of environment and operator influence, lack of detection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following examples are only preferred technical solutions of the present invention, and are not intended to limit the present invention in any way. Various modifications and variations of the present invention will occur to those skilled in the art. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

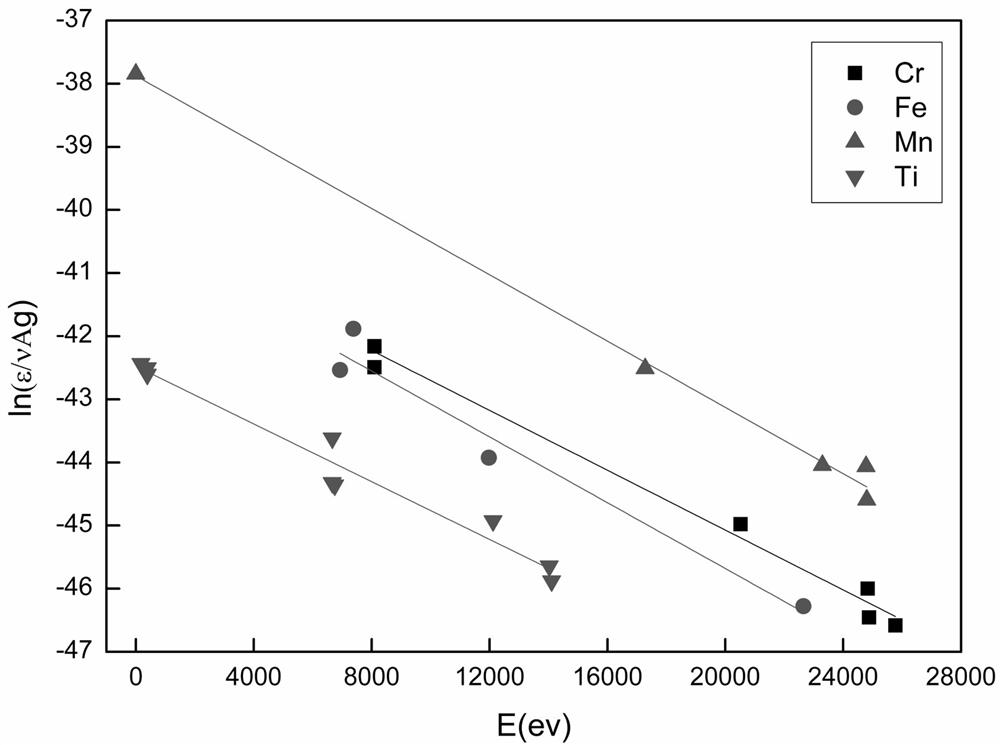

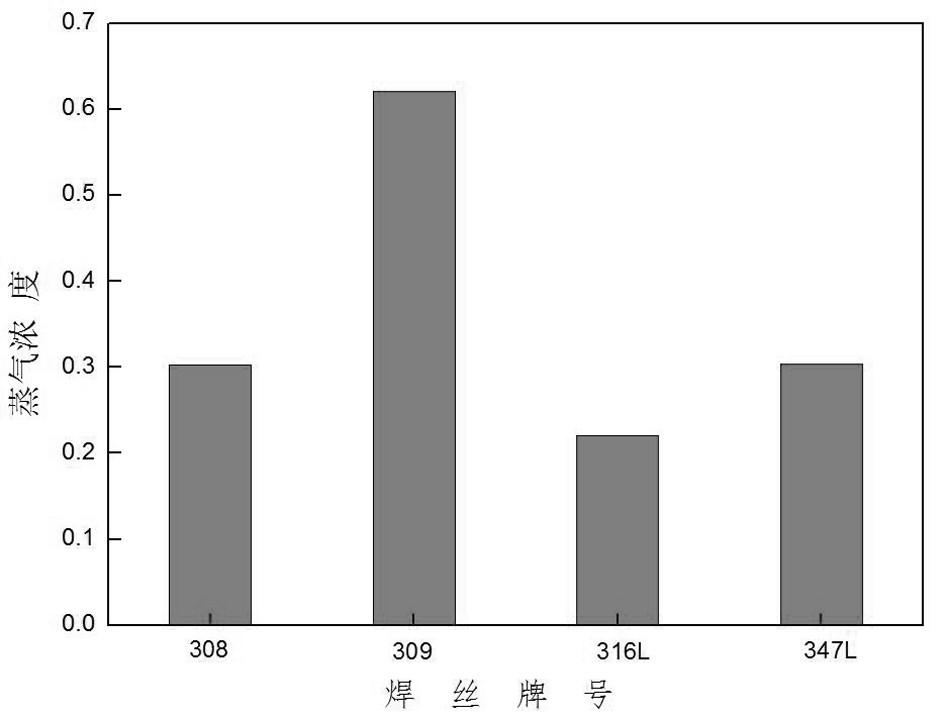

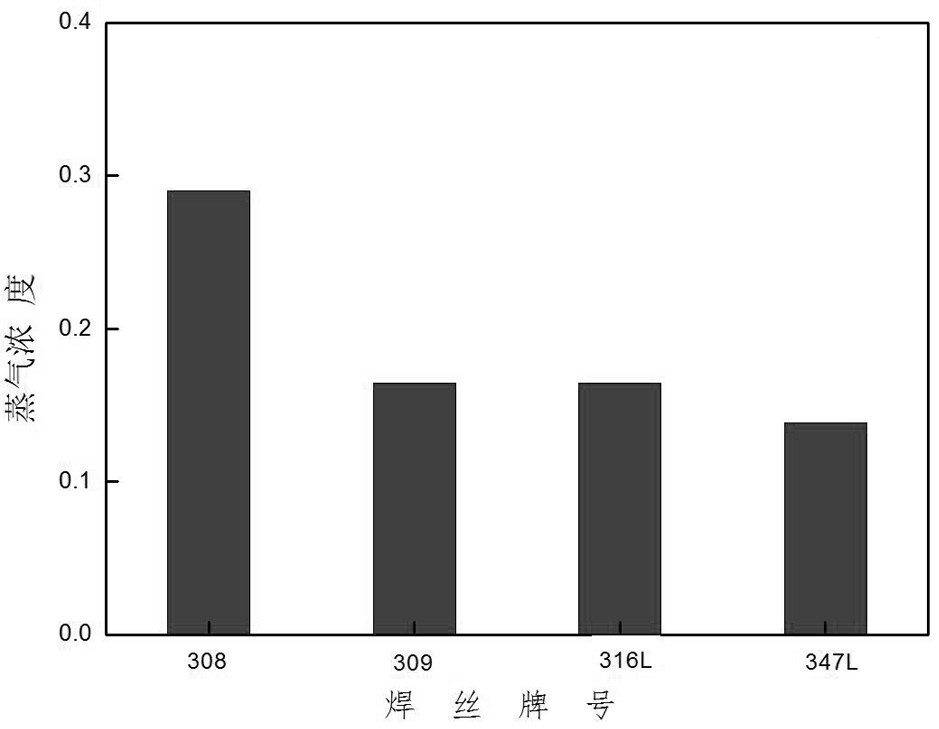

[0061] This embodiment adopts the detection method of the present invention to detect the concentration of welding arc pollution elements on four kinds of welding materials 308, 309, 316L and 347L produced by a certain manufacturer, and the detection objects include four main metal pollutants of Cr, Ti, Fe and Mn .

[0062] The detection process of Cr element is as follows.

[0063] Collect different instantaneous multi-frame welding arc spectrograms of 308, 309, 316L, 347L flux cored wires.

[0064] For each spectrogram,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com