Manufacture method of cheddar cheese

A technology of cheddar cheese and its production method, which is applied in the direction of dairy products, cheese substitutes, bacteria used in food preparation, etc., can solve the problems of time-consuming and energy-consuming, increase the production cost of cheese, and achieve energy saving and shorten processing maturity Periodic, continuous and stable effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

1. Specific examples

[0038] A method for making cheddar cheese, comprising the following steps:

[0039] (1) Preparation of starter

[0040]Streptococcus thermophilus and Lactobacillus bulgaricus were respectively activated on the slant for 3 generations, cultured for 18 hours, centrifuged at 5000rpm / min for 15 minutes, washed 3 times with normal saline after removing the supernatant, and adjusted the OD 600 To 1.0, after mixing Streptococcus thermophilus and Lactobacillus bulgaricus in a volume ratio of 2:1, inoculate pasteurized milk with an inoculation amount of 1% by volume, and ferment at 37°C for 10 hours to make fermentation agent;

[0041] (2) Inoculation fermentation

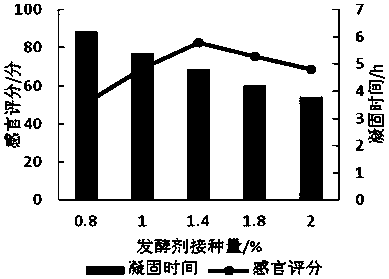

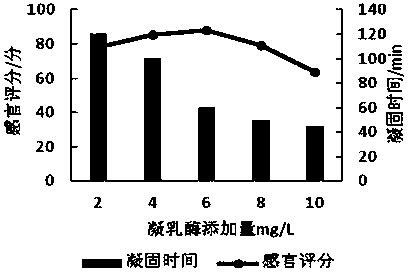

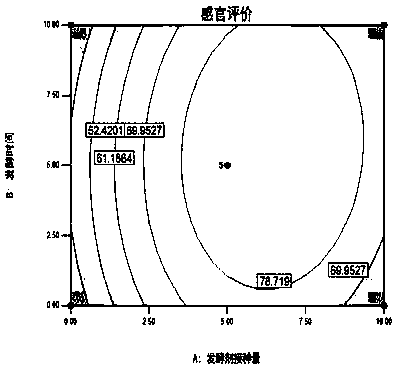

[0042] Pasteurize the fresh milk at 68°C for 30 minutes and cool it to room temperature, inoculate the starter into the pasteurized milk with an inoculation amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com