Preparation method of high-nutrition coarse cereal bread flour

A bread flour and high-nutrition technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of low nutrition level, sticking into blocks, crushing and grinding efficiency, and reach the nutritional level High, improve the effect of digestion and absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

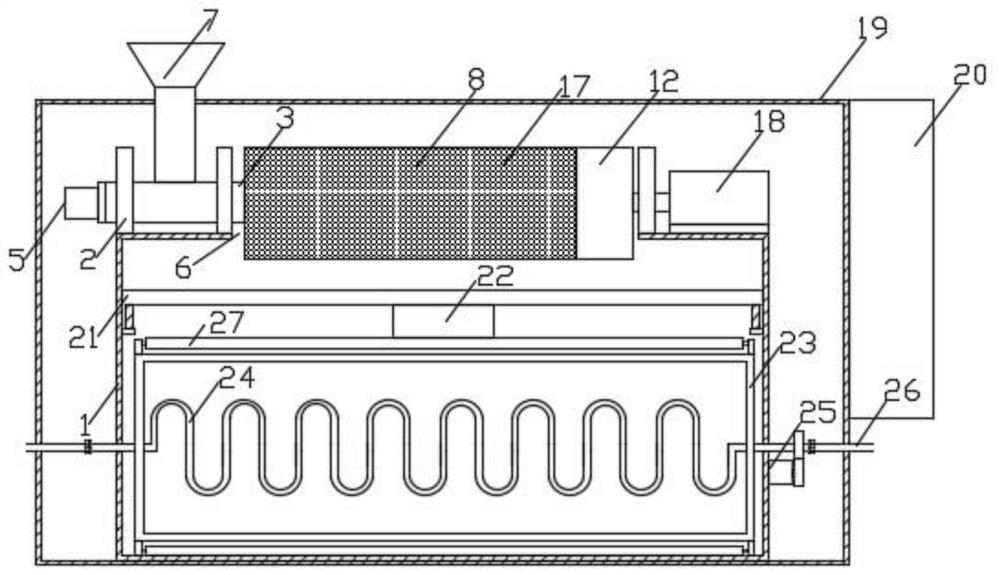

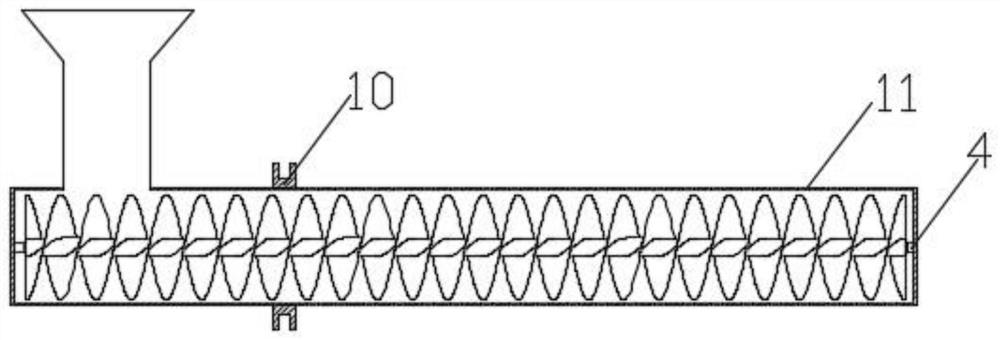

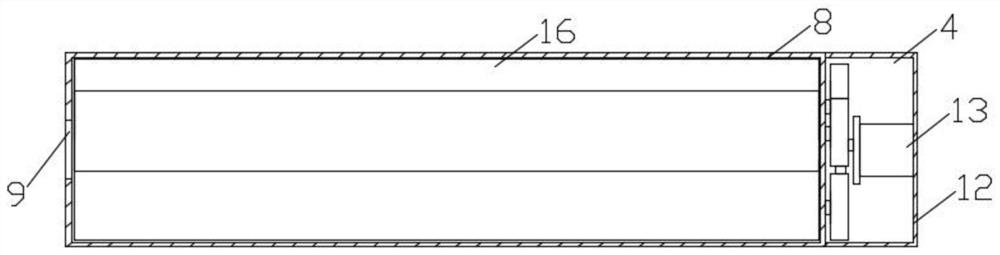

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of high-nutrition multigrain bread flour, comprising the steps of:

[0032] Step 1: Grind the wheat bran in a conventional way, then add 5 times the amount of soft water based on the mass of the wheat bran, conduct ultrasonic extraction at room temperature at 200W, 35KHz for 20min, and add 0.1% Mixed enzymes of high quality, hydrolyzed at 25°C for 1 hour, adjusted the pH to 3.0, hydrolyzed at 45°C for 1 hour, adjusted the pH to 5.0, hydrolyzed at 45°C for 1 hour, and inactivated the enzyme at 18MPa and 40°C Homogenizing, then concentrating under reduced pressure, and freeze-drying to obtain pre-wheat bran powder;

[0033] Step 2: Grind oat bran in a conventional way, then add 5 times soft water based on the mass of oat bran, add 0.02% mass of mixed enzyme preparation for enzymolysis, adjust the pH value to 4.5, and enzymolysis at 40°C for 2 hours , and then ultrasonically extract the enzymolysis solution at 40°C, 200W, 50KHz for 20min, homogenize a...

Embodiment 2

[0039] A preparation method of high-nutrition multigrain bread flour, comprising the steps of:

[0040] Step 1: Grind the wheat bran in a conventional way, then add 12 times the amount of soft water based on the mass of the wheat bran, conduct ultrasonic extraction at room temperature at 300W, 40KHz for 30min, and add 0.3% Enzyme hydrolyzate at 35°C for 2 hours, adjust the pH to 4.0, hydrolyze at 55°C for 2 hours, adjust the pH to 6.0, digest at 55°C for 2 hours, and inactivate the enzyme at 20MPa and 50°C Homogenizing, then concentrating under reduced pressure, and freeze-drying to obtain pre-wheat bran powder;

[0041] Step 2: Grind oat bran in a conventional way, then add 10 times soft water based on the mass of oat bran, add 0.05% by mass of mixed enzyme preparation for enzymolysis, adjust the pH value to 5.5, and enzymolysis for 4 hours at a temperature of 50°C , and then ultrasonically extract the enzymatic solution at 50°C, 400W, and 100KHz for 30 minutes, homogenize a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com