A kind of miscellaneous grain high-fiber flour and preparation method thereof

A miscellaneous grain and high-fiber technology, which is applied in the field of miscellaneous grain high-fiber flour and miscellaneous grain high-fiber flour preparation, can solve the problems of easy rancidity, miscellaneous grain composition, structure and characteristics, and restrict the development and production of miscellaneous grain flour, so as to improve digestion Absorption rate, improvement of taste and processing performance, effect of increasing gluten-free protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

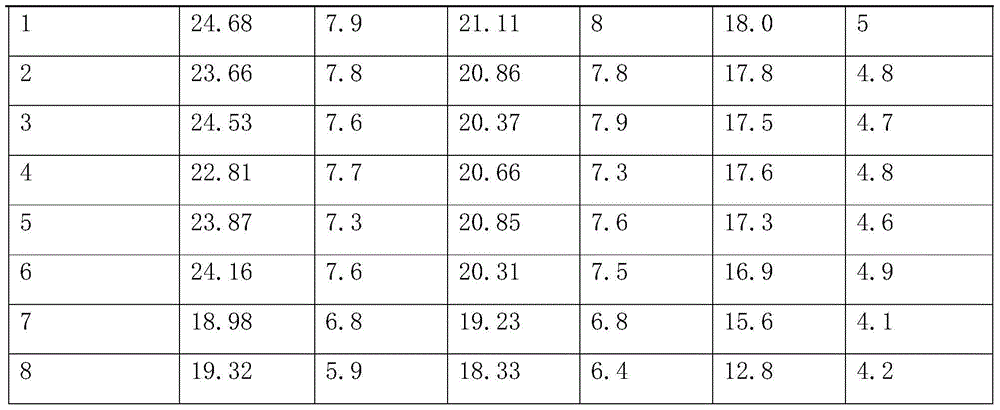

Examples

Embodiment 1

[0039] A multi-grain high-fiber flour, comprising the following parts by weight: high-gluten wheat flour: multi-grain bran powder = 7:1;

[0040] The mass fraction of cereal bran powder becomes: wheat bran powder: oat bran powder: corn flour=5:2:2;

[0041] The multi-grain high-fiber flour has a mixed smell of wheat and multi-grains, has a normal taste and no peculiar smell;

[0042] The dietary fiber content of the grains high-fiber flour is not less than 6.0%, and the wet gluten content is 30-36%;

[0043] Ash content (calculated on a dry basis), ≤2.80%;

[0044] Coarseness, all pass the CQ14 sieve;

[0045] Other indicators are:

[0046] Sand content, ≤0.02%; magnetic metal, ≤0.003g / kg; moisture ≤13.5%; fatty acid value (on wet basis), mgKOH / 100g, ≤80;

[0047] The above percentage "%" is the mass percentage;

[0048] A preparation method of multi-grain high-fiber flour includes the following steps:

[0049] After the raw material wheat is cleaned, impurity, and washed to obtain wheat gra...

Embodiment 2

[0063] A kind of multi-grain high-fiber flour includes the following parts by weight: high-gluten wheat flour: multi-grain bran powder=9:1;

[0064] The mass fraction of the cereal bran powder becomes: wheat bran powder: oat bran powder: corn flour=4:3:1;

[0065] The multi-grain high-fiber flour has a mixed smell of wheat and multi-grains, has a normal taste and no peculiar smell;

[0066] The dietary fiber content of the cereals high-fiber flour is not less than 6.0%, and the wet gluten content is 32-36%;

[0067] Ash content (calculated on a dry basis), ≤2.80%;

[0068] Coarseness, all pass the CQ14 sieve;

[0069] Other indicators are:

[0070] Sand content, ≤0.02%; magnetic metal, ≤0.003g / kg; moisture ≤13.5%; fatty acid value (on wet basis), mgKOH / 100g, ≤80;

[0071] The above percentage "%" is the mass percentage;

[0072] A preparation method of multi-grain high-fiber flour includes the following steps:

[0073] After the raw material wheat is cleaned, impurity, and washed to obtain w...

Embodiment 3

[0087] A multi-grain high-fiber flour, comprising the following parts by weight: high-gluten wheat flour: multi-grain bran powder=7:3;

[0088] The cereal bran powder is wheat bran powder and oat bran powder, and the ratio of wheat bran powder and oat bran powder is not limited;

[0089] The multi-grain high-fiber flour has a mixed smell of wheat and multi-grains, has a normal taste and no peculiar smell;

[0090] The dietary fiber content of the cereals high-fiber flour is not less than 6.0%, and the wet gluten content is 30-32%;

[0091] Ash content (calculated on a dry basis), ≤2.80%;

[0092] Coarseness, all pass the CQ14 sieve;

[0093] Other indicators are:

[0094] Sand content, ≤0.02%; magnetic metal, ≤0.003g / kg; moisture ≤13.5%; fatty acid value (on wet basis), mgKOH / 100g, ≤80;

[0095] The above percentage "%" is the mass percentage;

[0096] A preparation method of multi-grain high-fiber flour includes the following steps:

[0097] After the raw material wheat is cleaned, impurity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com