Binder for high-strength screen framework

An adhesive, high-strength technology, used in non-polymer adhesive additives, adhesive types, protein adhesives, etc. problems, to achieve the effect of improving heat resistance, high bonding strength, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

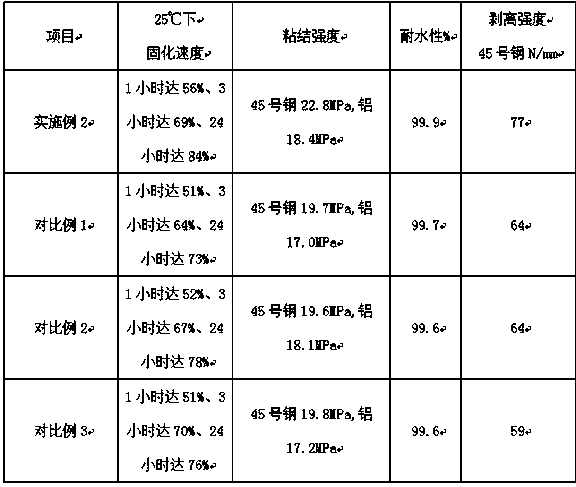

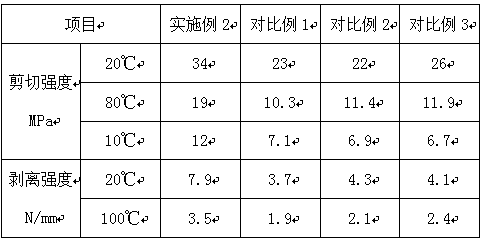

Examples

Embodiment 1

[0020] A binder for high-strength screen skeleton, made of the following raw materials in parts by weight:

[0021] 20 parts of defatted soybean meal, 39 parts of potassium hydroxide solution (mass fraction 20%), 97 parts of phenol, 121 parts of formaldehyde, 0.7 parts of polyamine, 5 parts of vinyl silicone rubber, 2.8 parts of diphenylsilanediol, 2, 1.5 parts of 5-di-tert-butylperoxy-2,5-dimethylhexane, 0.9 parts of melamine, 6 parts of polyimide, 3.1 parts of terpene resin, 32 parts of vinyl acetate, 4 parts of n-propanol, 3.5 parts of hydroquinone, 7 parts of boric acid, 68 parts of diphenyl dichlorosilane, 8 parts of dimethyl dichlorosilane, 4 parts of propyl gallate, 0.6 parts of cyclohexylphenyl-p-phenylenediamine, 0.8 parts of coal tar parts, 17 parts of sepiolite powder, 8 parts of polyethylene glycol, and 35 parts of alkaline lignin processing waste liquid.

[0022] A kind of binder for high-strength screen mesh skeleton, its preparation method comprises the followi...

Embodiment 2

[0026] A binder for high-strength screen skeleton, made of the following raw materials in parts by weight:

[0027] 26 parts of defatted soybean meal, 45 parts of potassium hydroxide solution (mass fraction 20%), 113 parts of phenol, 135 parts of formaldehyde, 1.1 parts of polyamine, 11 parts of vinyl silicone rubber, 3.3 parts of diphenylsilanediol, 2, 2 parts of 5-di-tert-butylperoxy-2,5-dimethylhexane, 1.2 parts of melamine, 6 parts of polyimide, 5.5 parts of terpene resin, 45 parts of vinyl acetate, 5 parts of n-propanol, 5.5 parts of hydroquinone, 8 parts of boric acid, 54 parts of diphenyl dichlorosilane, 6 parts of dimethyl dichlorosilane, 4 parts of propyl gallate, 0.6 parts of cyclohexylphenyl-p-phenylenediamine, 1.4 parts of coal tar parts, 22 parts of sepiolite powder, 8 parts of polyethylene glycol, and 35 parts of alkaline lignin processing waste liquid.

[0028]A kind of binder for high-strength screen mesh skeleton, its preparation method comprises the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com