Device for separating oil-containing silt by liquid-state CO2

A CO2, liquid technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problems of incomplete removal, secondary pollution, high cost, etc., to achieve mature liquefaction technology, complete separation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

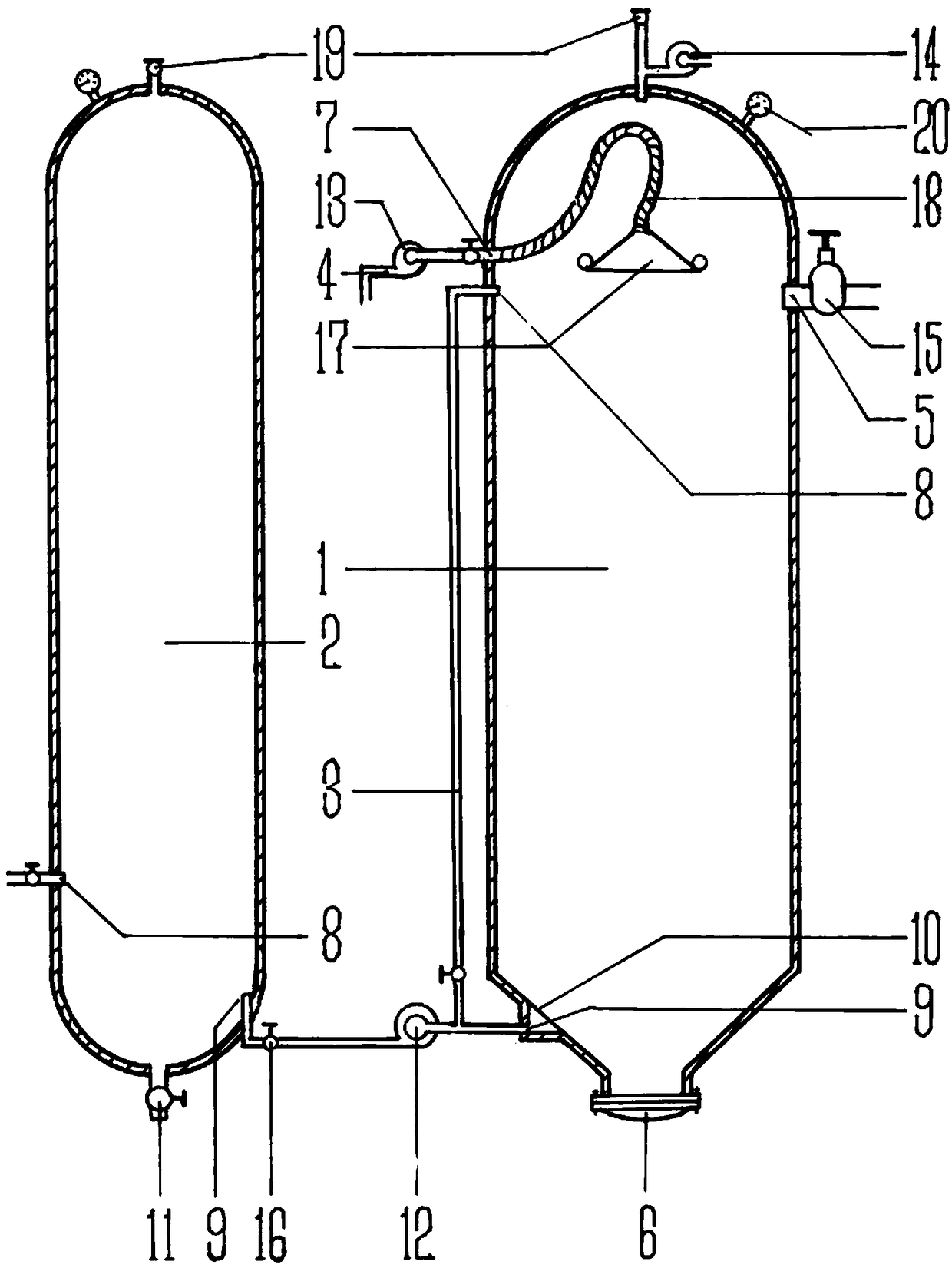

[0015] In conjunction with the accompanying drawings, the present invention is described in further detail below:

[0016] Such as figure 1 Shown, liquid CO 2 The oily sediment separation device is mainly composed of separation tower 1 and liquid CO 2 The storage tank 2 is composed of two parts, both of which are steel cylindrical sealed structures capable of withstanding a pressure of 15 MPa. An oily sediment inlet 5 controlled by a cut-off valve 15 is arranged on the side wall of the upper part of the separation tower 1. The bottom umbrella shape is narrowed, and the central position is designed as a sediment outlet 6 closed by a flange cover plate. The middle part of the hypotenuse is designed by a The CO separated by the filter membrane 10 and protruding outward 2 import and export9. Set oil-water outlet 7 and CO on the opposite side wall of oily sediment inlet 5 2 Entrance 8. The oil-water outlet 7 is connected inwardly to the umbrella-shaped oil collecting cover 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com