High hardness and low temperature reinforced porcelain product and sintering technology thereof

A low-temperature strengthening and high-hardness technology, applied in the field of low-temperature strengthening ceramic products, can solve the problems of unstable ceramic performance, low firing temperature and high cost, and achieve the effects of improving water resistance, reducing firing temperature and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

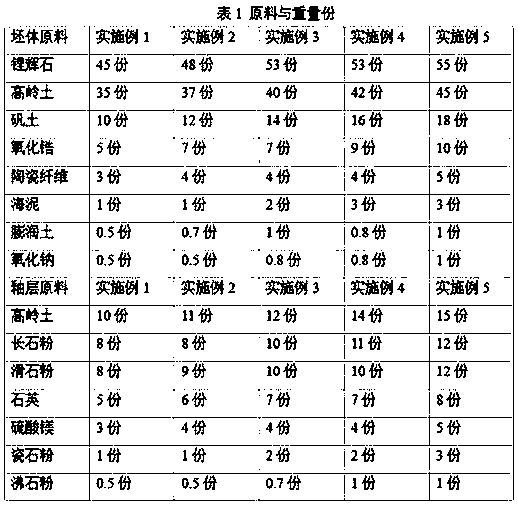

[0026] This embodiment provides a high-hardness low-temperature strengthened porcelain product, including a green body and a glaze layer applied on the green body. The green body includes the following raw materials in parts by weight: 45 parts of spodumene, 35 parts of kaolin, and 10 parts of alumina. parts, 5 parts of zirconia, 3 parts of ceramic fiber, 1 part of sea mud, 0.5 parts of bentonite, and 0.5 parts of sodium oxide; the glaze layer includes the following raw materials in parts by weight: 10 parts of kaolin, 8 parts of feldspar powder, and 8 parts of talcum powder , 5 parts of quartz, 3 parts of magnesium sulfate, 1 part of porcelain stone powder, and 0.5 part of zeolite powder; wherein, the feldspar powder is a mixture of potassium feldspar and albite with a weight ratio of 3:1.

[0027] This embodiment also provides a firing process for high-hardness low-temperature strengthened porcelain products, including the following steps:

[0028] Step 1: take each raw mate...

Embodiment 2

[0036] This embodiment provides a high-hardness low-temperature strengthened porcelain product, including a green body and a glaze layer applied on the green body. The green body includes the following raw materials in parts by weight: 48 parts of spodumene, 37 parts of kaolin, 12 parts of alumina 1 part, 7 parts of zirconia, 4 parts of ceramic fiber, 1 part of sea mud, 0.7 part of bentonite, 0.5 part of sodium oxide; the glaze layer includes the following raw materials in parts by weight: 11 parts of kaolin, 8 parts of feldspar powder, and 9 parts of talcum powder , 6 parts of quartz, 4 parts of magnesium sulfate, 1 part of porcelain stone powder, and 0.5 part of zeolite powder; wherein, the feldspar powder is a mixture of potassium feldspar and albite with a weight ratio of 3:4.

[0037] This embodiment also provides a firing process for high-hardness low-temperature strengthened porcelain products, including the following steps:

[0038] Step 1: take each raw material accor...

Embodiment 3

[0046] This embodiment provides a high-hardness low-temperature strengthened porcelain product, including a green body and a glaze layer applied on the green body, the green body includes the following raw materials by weight: the green body includes the following raw materials by weight: spodumene 53 parts of stone, 40 parts of kaolin, 14 parts of bauxite, 7 parts of zirconia, 4 parts of ceramic fiber, 2 parts of sea mud, 1 part of bentonite, and 0.8 part of sodium oxide; the glaze layer includes the following raw materials in parts by weight: kaolin 12 10 parts, 10 parts of feldspar powder, 10 parts of talcum powder, 7 parts of quartz, 4 parts of magnesium sulfate, 2 parts of porcelain stone powder, and 0.7 part of zeolite powder; wherein, the feldspar powder is potassium feldspar and sodium A mixture of feldspars.

[0047] This embodiment also provides a firing process for high-hardness low-temperature strengthened porcelain products, including the following steps:

[0048...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap