Low-VOC (volatile organic compound) polyurethane foam as well as preparation method and application thereof

A technology of polyurethane foam and foaming agent, applied in transportation and packaging, roofing, vehicle parts, etc., can solve the problems of low elongation at break and high VOC value of polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

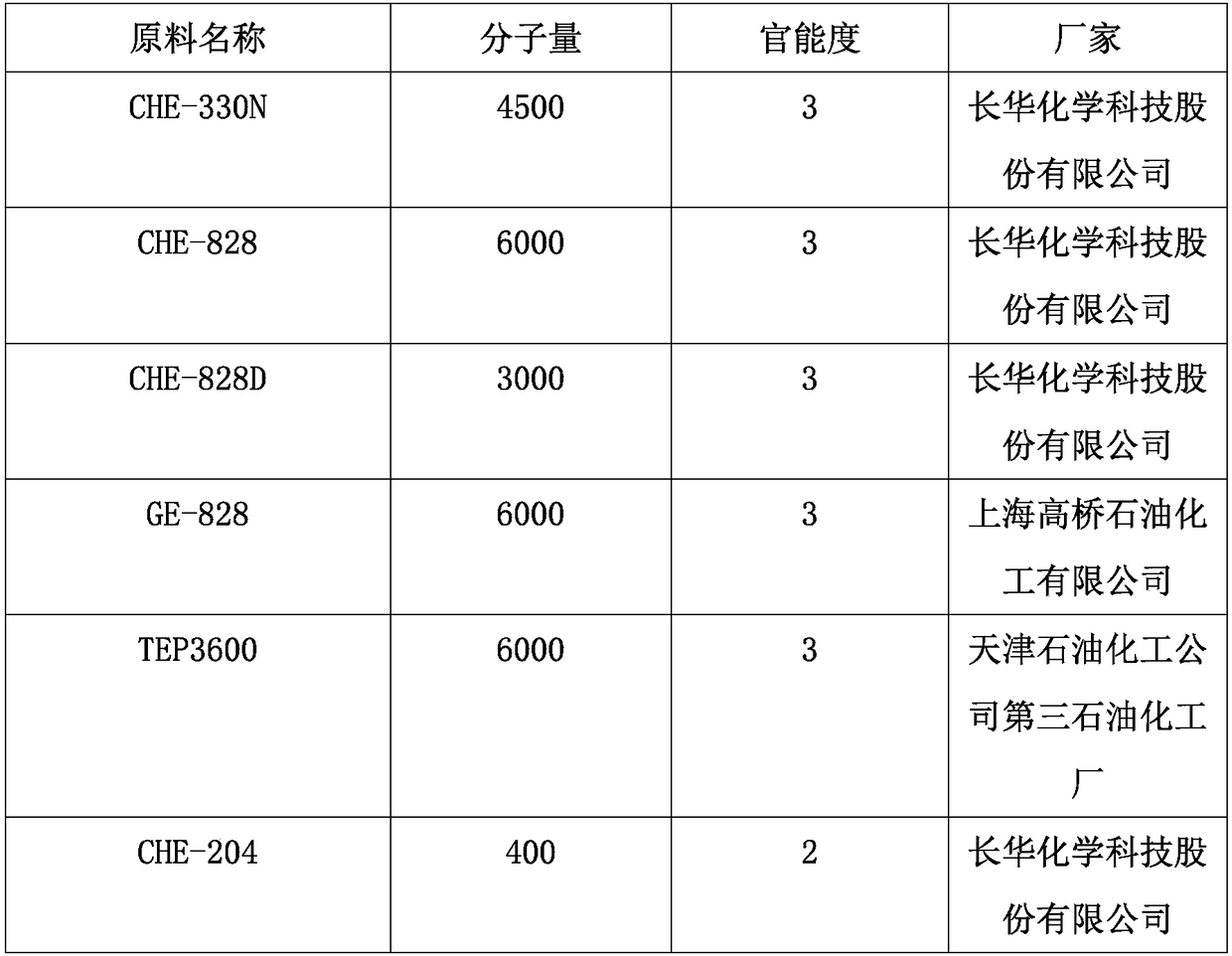

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare component A: 100kg, add CHE-828D: 40kg, CHE-204: 40kg, Multranol 9151: 13kg, water: 3kg, glycerin: 2kg, TMR-2: 1kg, L-5309 into the foaming container : 1kg, the stirring time is 60min, the stirring temperature is 20°C, and component A is obtained after standing;

[0024] (2) Preparation of component B: diphenylmethane diisocyanate (MDI): 30kg and polyphenylpolymethylene polycyanate (PAPI): 70kg, the stirring time is 60min, the stirring temperature is 20°C, and stand That is component B;

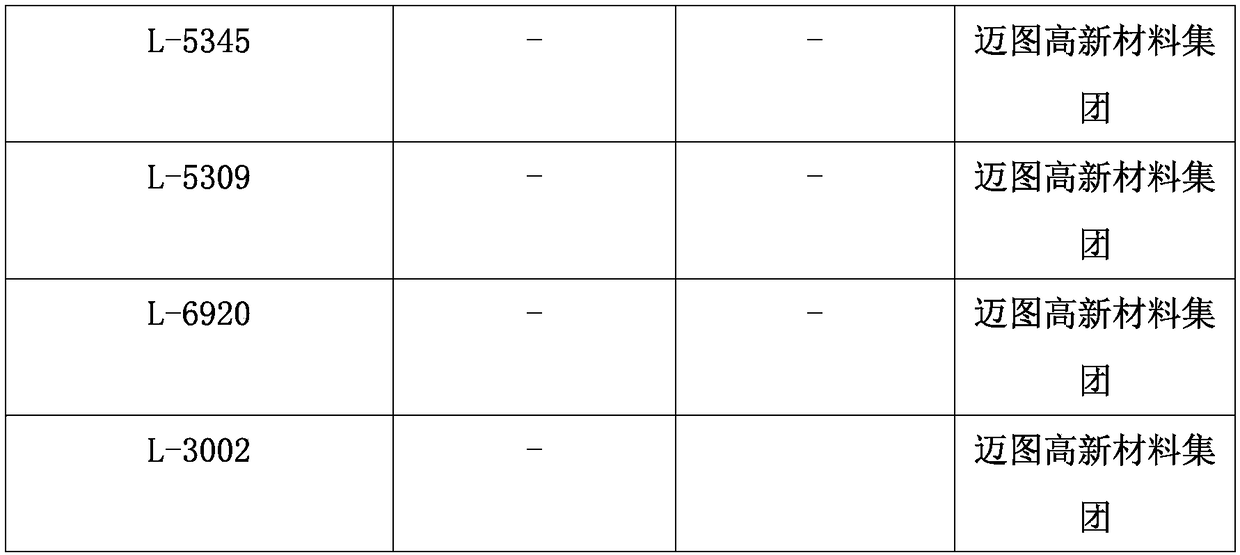

[0025] (3) Prepare polyurethane foam: mix weighed component A and component B, pour into the mold after stirring and foam freely to obtain polyurethane foam, wherein the weight percentage of component A and component B is 1:1, The reaction time is 40 min, and the reaction temperature is 15°C. The quality of the foam product and the detected VOC value are shown in Table 3.

Embodiment 2~5

[0027] The experiments of Example 2 to Example 5 were carried out according to the steps of Example 1, the only difference being that the types and ratios of raw materials were different, as shown in Table 2. The quality of the foam product and the detected VOC value are shown in Table 3.

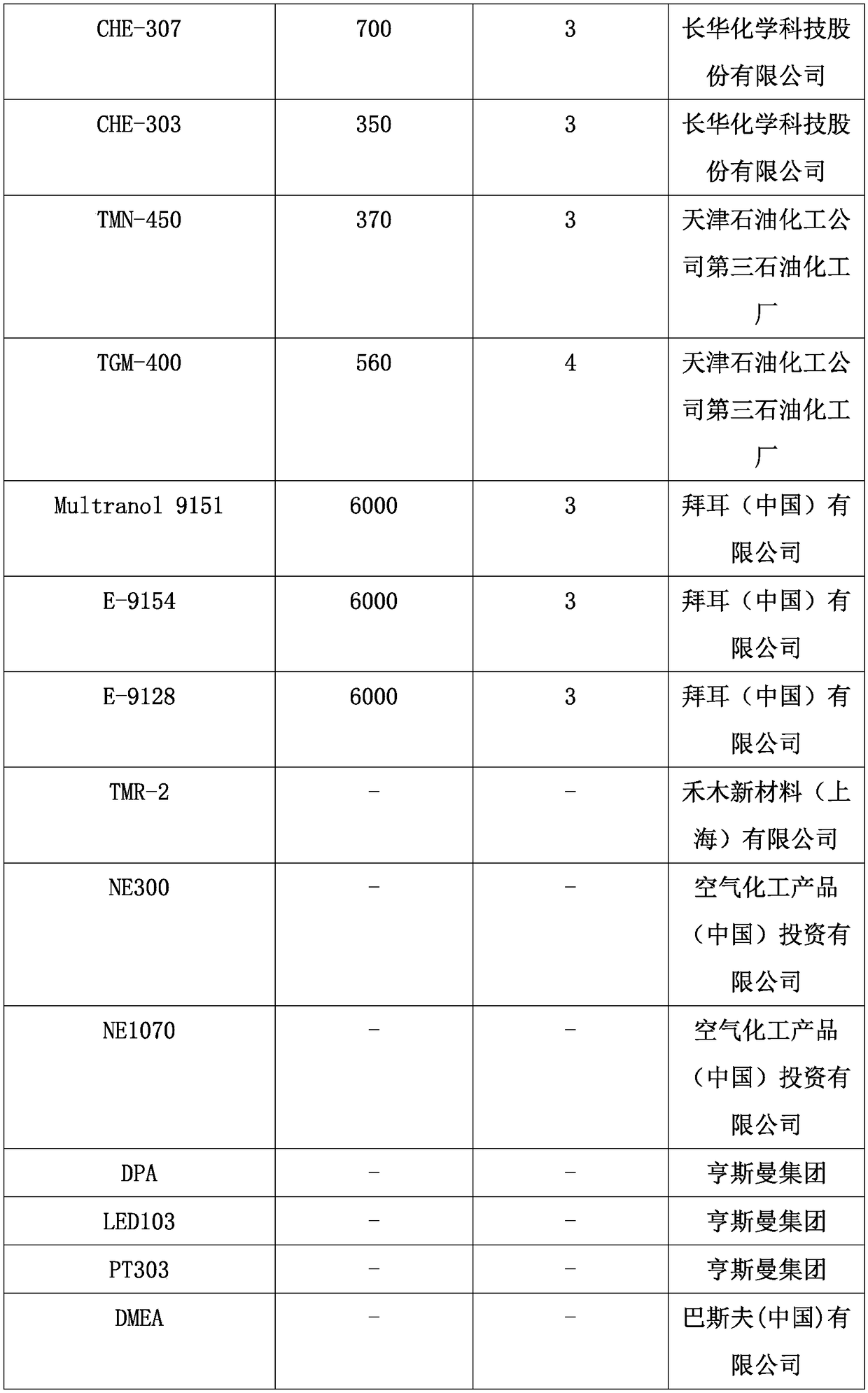

[0028] The weight percent of each component in table 2 embodiment 1 to embodiment 5

[0029]

[0030]

[0031]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap