Titanium dioxide aluminum coating technology with cost advantage

An aluminum coating, titanium dioxide technology, applied in inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve problems such as the decrease of bulk density and the effect of product gloss, and achieve the effect of reducing the amount of acid and alkali and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

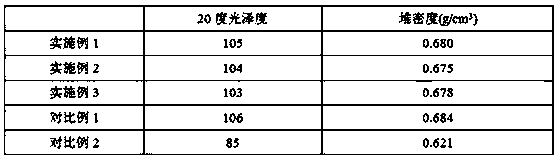

Examples

Embodiment 1

[0023] A kind of titanium dioxide aluminum coating process with cost advantage comprises the following steps: adopting mass concentration is 40g / L (as Al 2 o 3 count) NaAlO 2 The solution adjusts the pH value of the titanium dioxide slurry to 8-11; the NaAlO with a mass concentration of 40g / L 2 The solution and the mass concentration are 40g / L (as Al 2 o 3 count) AlCl 3 The solution is added to the titanium dioxide slurry in parallel, and the pH value of the slurry is controlled to be 8-11; the sulfuric acid solution with a mass concentration of 3% and NaAlO with a mass concentration of 40g / L 2 The solution is added into the slurry in parallel, and the pH value of the slurry is controlled to be 8-11, and the amount of aluminum coating in this step is 0.2%; the pH value of the slurry is adjusted to 6 with a sulfuric acid solution with a mass concentration of 3%. -8. After aging for 30-90 minutes, the reaction is completed, filtered and washed, and then dried to obtain the ...

Embodiment 2

[0025] A kind of titanium dioxide aluminum coating process with cost advantage, comprises the following steps: adopting mass concentration is 100g / L (as Al 2 o 3 count) NaAlO 2 The solution adjusts the pH value of the titanium dioxide slurry to 8-11; the NaAlO with a mass concentration of 100g / L 2 The solution and the mass concentration are 100g / L (as Al 2 o 3 count) AlCl 3 The solution is added to the titanium dioxide slurry in parallel, and the pH value of the slurry is controlled to be 8-11; the hydrochloric acid solution with a mass concentration of 10% and the NaAlO solution with a mass concentration of 100g / L 2 Solution co-flows into the slurry, and the pH value of the control slurry is 8-11, and the aluminum coating amount in this step is 0.5% of the total aluminum coating amount; The pH value is adjusted to 6-8, the reaction is completed after aging for 30-90 minutes, filtered and washed, and then dried to obtain the finished product.

Embodiment 3

[0027] A kind of titanium dioxide aluminum coating process with cost advantage comprises the following steps: adopting mass concentration is 150g / L (as Al 2 o 3 count) KAlO 2 The solution adjusts the pH value of the titanium dioxide slurry to 8-11; the KAlO with a mass concentration of 150g / L 2 The solution and the mass concentration are 150g / L (as Al 2 o 3 Gauge) Al 2 (SO 4 ) 3 The solution is added to the titanium dioxide slurry in parallel flow, and the pH value of the slurry is controlled to be 8-11; the nitric acid solution with a mass concentration of 30% and the KAlO solution with a mass concentration of 150g / L 2 The solution is added into the slurry in parallel, and the pH value of the slurry is controlled to be 8-11, and the aluminum coating amount in this step is 0.8%; the pH value of the slurry is adjusted to 6-10 with a nitric acid solution with a mass concentration of 30%. 8. After aging for 30-90 minutes, the reaction is completed, filtered and washed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com