PH regulation method in high fructose corn syrup production process

A production process and technology of high fructose syrup, applied in the directions of fructose production, sugar production, sugar production, etc., can solve the problems of increased acid-base consumption, increased production cost, increased introduction of relevant impurity ions, etc. The effect of reducing acid and alkali consumption and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

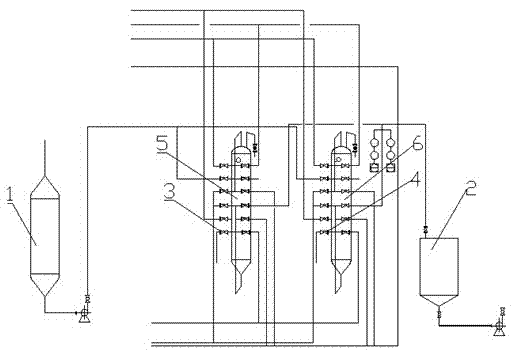

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention, but the present invention is not limited thereto.

[0020] pH adjustment method in the fructose syrup production process, the method comprises the following steps:

[0021] The material whose pH value is to be adjusted is transported to the front tank for pH adjustment, and pumped into two parallel ion exchange columns I and II. The material is ion exchanged in the two ion exchange columns, and the lower parts of the two ion exchange columns are respectively There are sampling valve I3 and sampling valve II4, through which the pH value is monitored; when the pH value of the material is between 7.5-7.8, the ion exchange is stopped, and the material adjusted to the required pH is transported to the adjusted tank.

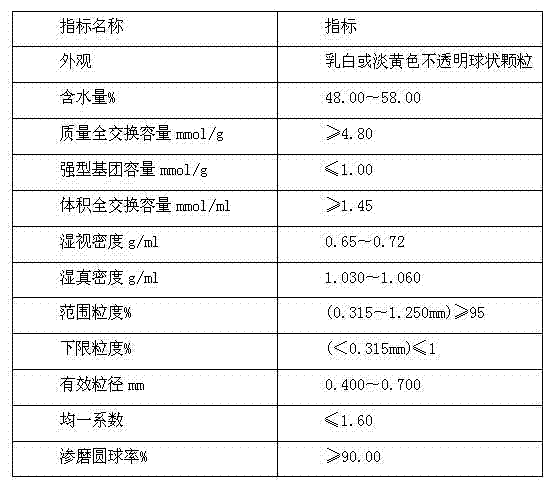

[0022] The resin in the ion exchange column accounts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com