Thin film capacitor metal spraying machine longitudinal spraying range characterization control system

A film capacitor and control system technology, which is applied in the direction of film/thick film capacitors, laminated capacitors, metal material coating technology, etc., can solve the problems of high equipment failure rate, waste of spraying materials, dissatisfaction of discharge, etc., and achieve equipment failure rate The effect of low and simplified peripheral circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

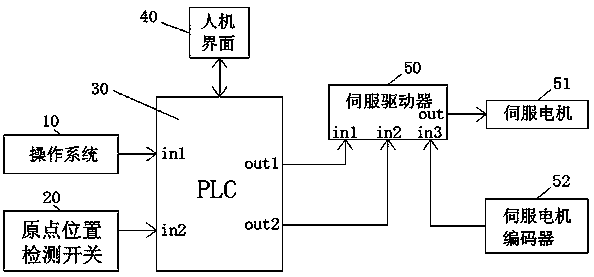

[0030] The position resolution of the servo motor is 1mm, the spraying start position is 3500mm away from the origin position, and the spraying stop position is 4100mm away from the origin position. , the control system automatically calculates that the number of CP pulses representing the distance between the spraying position and the origin position is 3500, and the number of CP pulses representing the distance between the spraying stop position and the origin position is 4100; press the start button of the operating system (10) Finally, the servo drive system drives the main chain to run to a distance of 3500mm from the origin to start spraying, and when the main chain runs to a distance of 4100mm from the origin to stop spraying; when the spraying ends, the servo drive system drives the main chain to run in reverse, when the origin is detected Stop when detecting switch (20).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com