Core tube shaft structure of super high-rise building

A core tube and shaft structure technology, which is applied in building components, special structures, building structures, etc., can solve the problems of horizontal ribs affecting the climbing of the top form, complicated construction process, unfavorable progress and quality of core tube construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

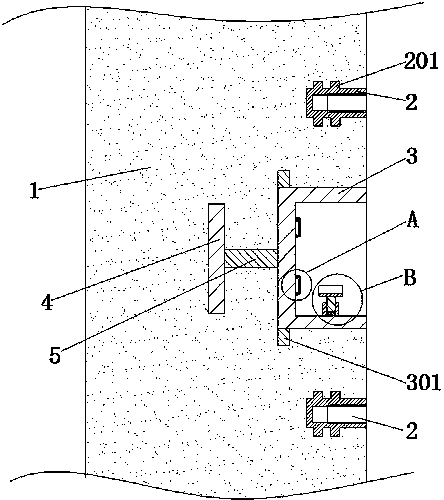

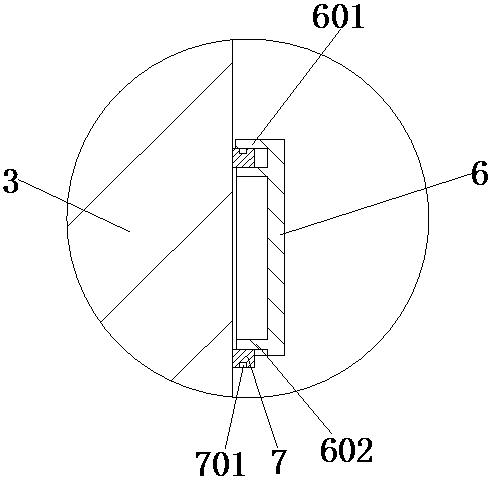

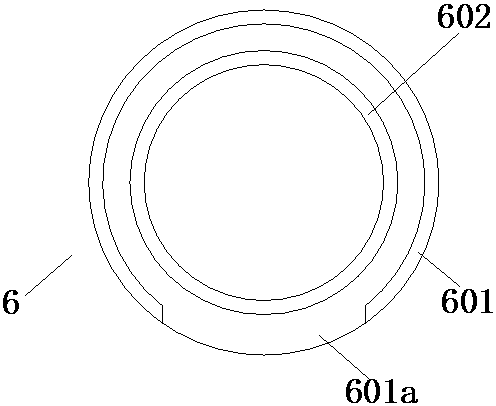

[0025] Such as Figures 1 to 5 Shown, a kind of super high-rise building core tube axle structure described in the present invention, it comprises wall body 1 and support member; The inside of described wall body 1 is pre-embedded with channel steel 3; The axial direction of described channel steel 3 The direction and the horizontal plane are arranged parallel to each other; the opening end face of the channel steel 3 and the side surface of the wall 1 are arranged in the same vertical plane; the bottom of the channel steel 3 is fixed with several connecting rods 5; The end of the rod 5 is fixed with a circular plate 4; the connecting rod 5 and the circular plate 4 are pre-embedded behind the wall 1, so that the channel steel 3 is fixed in the wall 1 as a whole, and the channel steel 3 will not face the wall in this structure. The body forming sliding form slides on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap