Gas heater

A heater and gas technology, applied in household heating, lighting and heating equipment, household heating, etc., can solve problems such as poor airflow, achieve the effects of saving usage, avoiding poor airflow, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

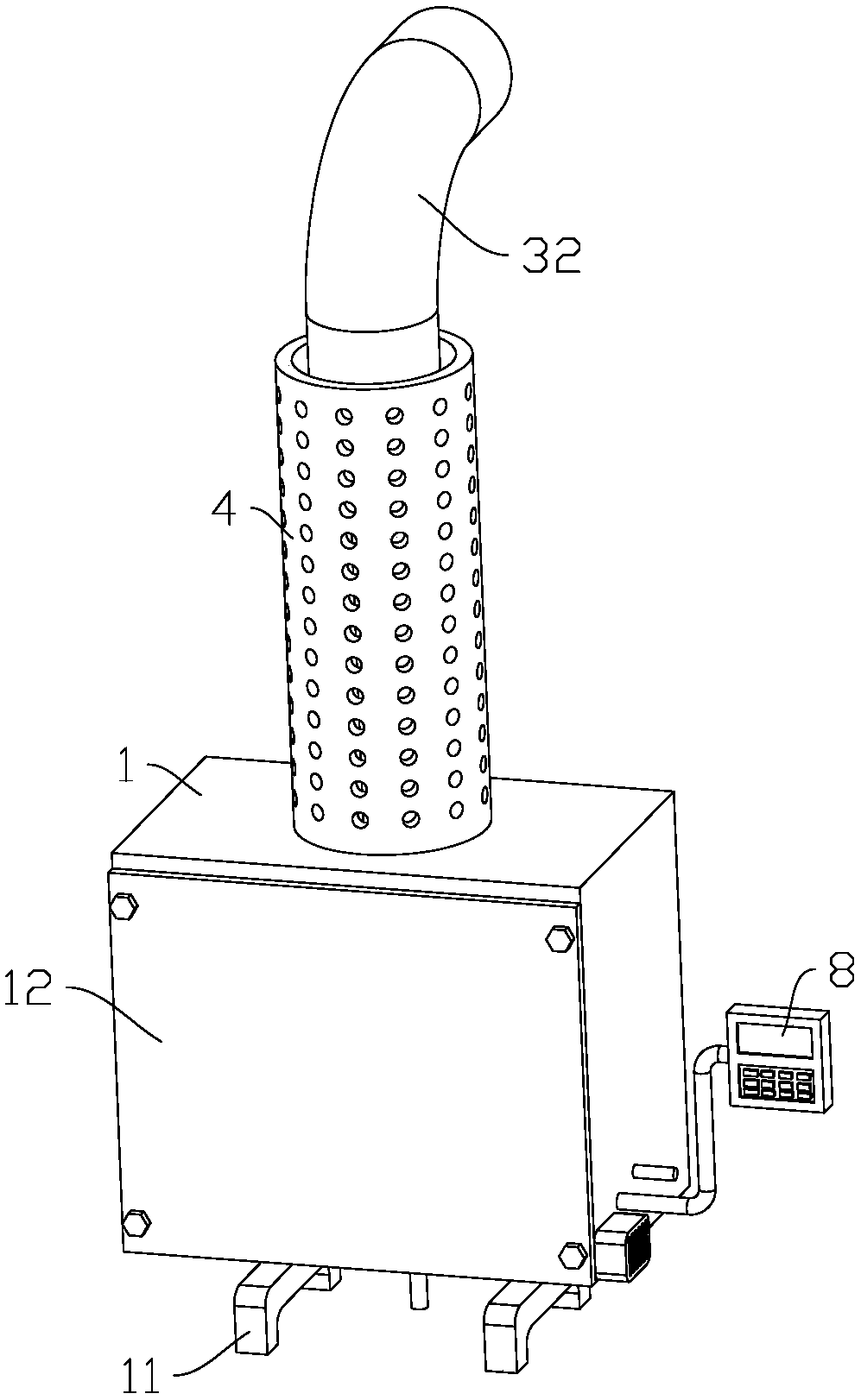

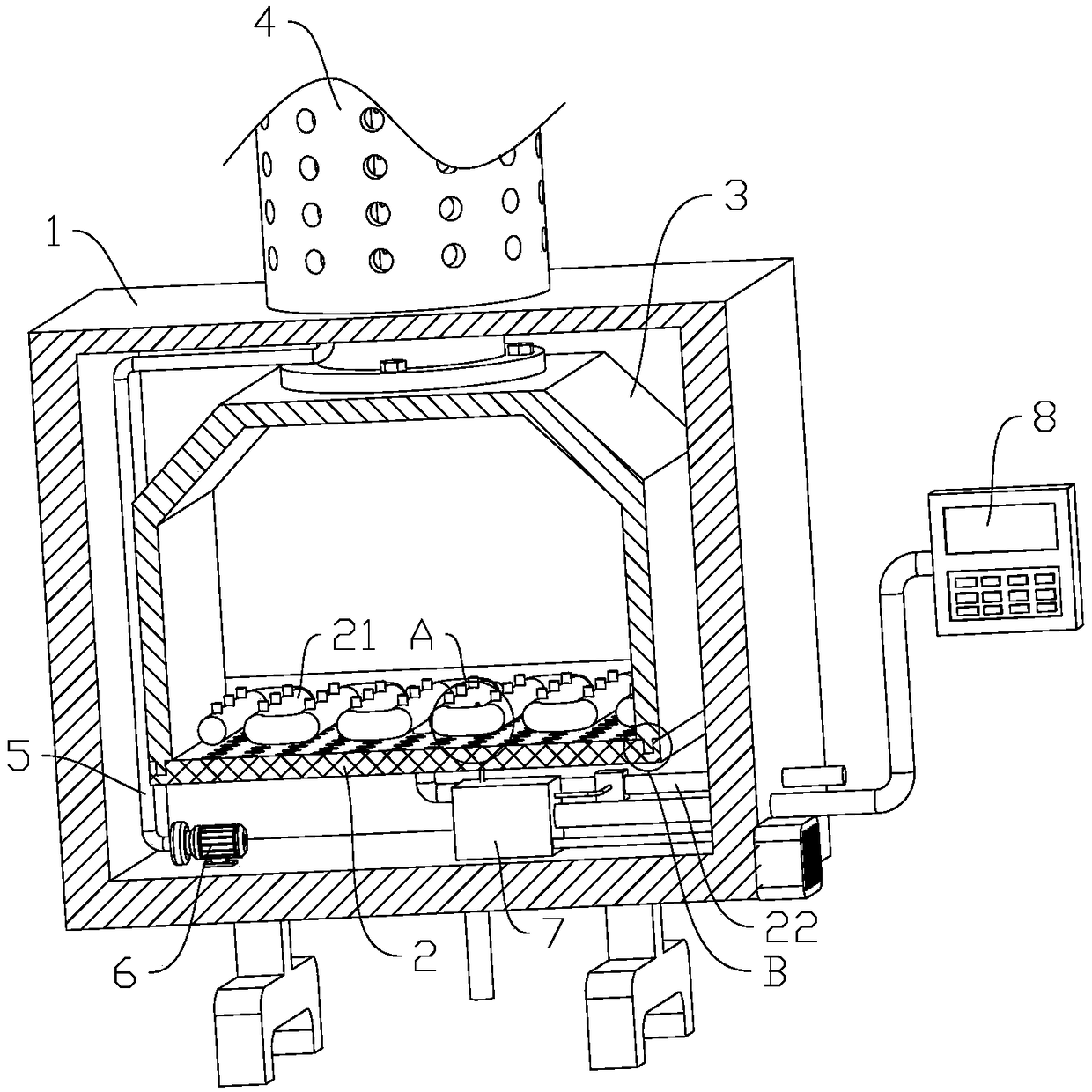

[0041] This embodiment discloses a gas heater, such as figure 1 As shown, it includes a housing 1 with an exhaust port, wherein the exhaust port is set upward to facilitate the exhaust gas to rise away from the housing 1, and the bottom of the housing 1 is detachably connected with several legs 11 to support the housing 1. In this embodiment Two legs 11 are provided, and a mounting opening is opened on one side of the housing 1 and a baffle 12 is detachably connected thereto.

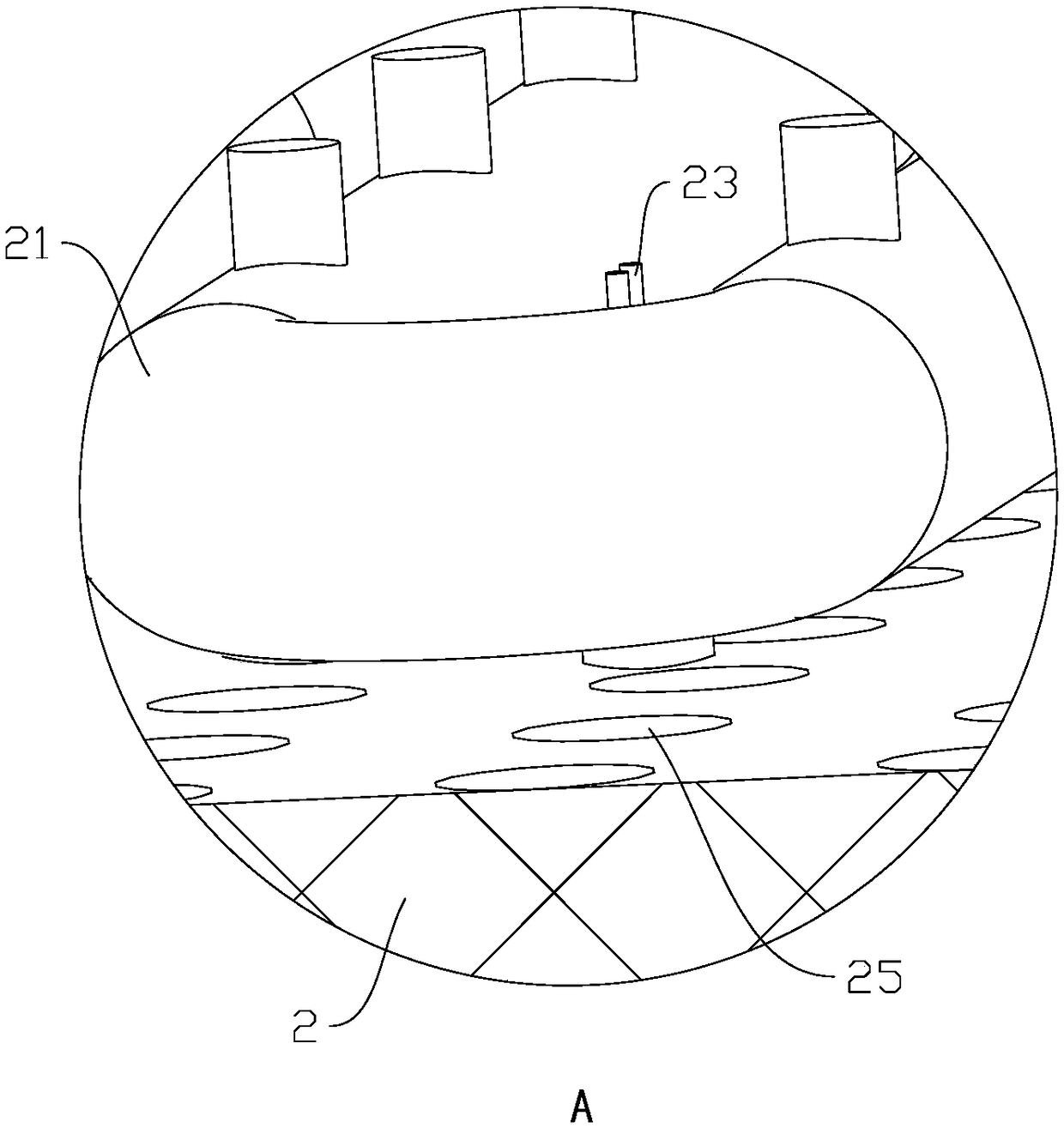

[0042] combine figure 2 , image 3 and Figure 4 , the housing 1 is provided with a combustion platform 2, the combustion platform 2 is detachably installed on the side of the housing 1 away from the installation port through screws, and there is a certain gap between the bottom of the housing 1, and the combustion platform 2 is installed with Fire row 21, intake pipe 22 for supplying gas and igniter 23; a cover body 3 is also clipped on the combustion platform 2 to divide the casing 1 into a cavity a...

Embodiment 2

[0052] This embodiment discloses a gas heater, which combines Figure 6 and Figure 8 The main difference from Embodiment 1 is that an inner tube 324 is arranged in the air duct 32, and the end of the air duct 32 away from the outdoor communicates with the combustion chamber, and the end of the inner tube 324 away from the outdoor runs through the side wall of the air duct 32 and communicates with the cavity. The inner side of the air duct 32 and the outer side of the inner tube 324 form a smoke exhaust channel 322, and the inner side of the inner tube 324 is an air intake channel 323. At this time, the outer wall of the air duct 32 is equidistantly arranged with a plurality of cooling tubes attached to the air duct 32. 5. The corresponding protective cover 4 is circumferentially provided with through holes 41 corresponding to the heat dissipation holes 51 of the heat dissipation pipe 5. In order to strengthen the structural stability of the inner pipe, a number of holes are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com