Three-dimensional non-orthogonal tracking and scanning test head calibrating method

A technology of scanning probe and calibration method, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of not being able to reflect the working conditions of the internal sensors of the three-dimensional non-orthogonal tracking scanning probe, adverse effects on accuracy, and large calibration errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

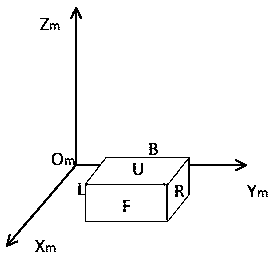

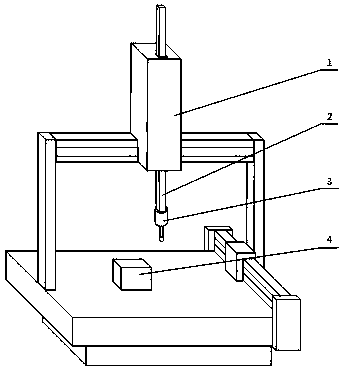

[0033] Step 1 Install the standard measuring cube Q ,Such as figure 1 shown, and operate a CMM using a variety of methods such as a calibrated touch probe or optical scanning to ensure its left L with front surface F machine coordinate axis , machine tool coordinate axis parallel, and read out its mounting coordinates, including: its front surface F , back surface B Corresponding machine coordinate axis coordinate value , left side L , right side R Corresponding machine coordinate axis coordinate value , on top U Corresponding machine coordinate axis Axis coordinate value . CMM C Install a three-dimensional non-orthogonal tracking scanning probe on the z-axis P (hereinafter referred to as the probe P ),Such as figure 2 shown.

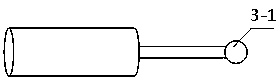

[0034] Step 2 Jog to control the three-coordinate measuring machine C drive probe P move so that the probe P ball finger I (Such as image 3 shown) with standard measuring cubes Q the front surface of F contact, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com